Yeah that thing amazed me, just up and over everything except that wall in the picture. It would have made it but it pulled the boulder under itself on the first attempt and then we just could not figure a way over it.

Super fun to watch it come together from a little green suzuki to a stretched frame on both ends and losing nearly all the body panels, and a motor swap. Completely different animal now.

I had not planned on the three SSR’s for the touch probing. Instead of moving everything around I made a bit of a cheat. This was supposed to just be to make sure they would fit then make it a little nicer. Well, I added all the chamfers, and then decided it needed to get a render even though no one else will ever need this exact part. I think I needed some seat time.

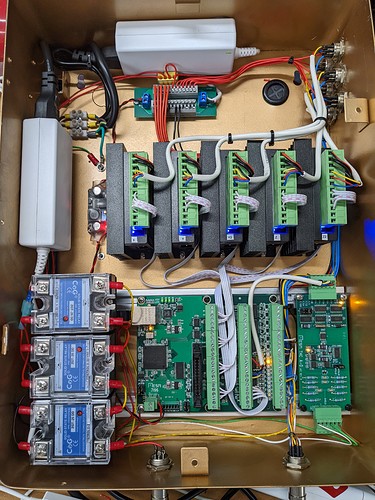

All wired up. Everything seems to work, ohmic seems ready. So just solder a couple more external plugs and swap out my LR brains. I never seem to get too much time with it, this pace is killing me.

If it makes you feel any better, I bought a new table saw fence back when Covid hit and work sent us all home - March of 2020. I got the rails installed 2 nights ago. Now I need to splice some surplus countertops to rebuild the extension tables. If past performance is any guide, that will be another 18 months.

It’s taken me 3 days to glue 2 pieces of PVC pipe together on my current project.

I have a half day at work today, so hope to make much more progress on that project.

That’s nothing. I started a project over seven years ago and he still hasn’t moved on to college. Kids take forever!

Tell him this is his high school graduation gift.

What do I use for CAM? I never even thought about this. I know linuxcnc can do basic shapes on its own but can I just drop in a DXF and tell it what side to pierce on and go, or do I need to use Estlcam?

I don’t have a plasma myself, but would expect it would be kind of like needing the lead-ins for cutting vinyl, as you don’t want the punch-through to be right on your cut line.

Yeah I just started reading through a bit more. It has so many fancy features for offsets, recovery, common shapes, recovery, and consumables changing. But yes, it looks like you still need estlcam or other CAM. Seems kinda obvious now.

Getting pretty excited, I even had dreams about it last night…sometimes you just can’t turn it off.

LinuxCNC doesnt run dxf files, you’ll need to run it through cam like usual.

I use sheetcam, there’s a trial version but I broke down and purchased the license. There is a plasmac post.

You could probably get estlcam to work but I guess you’d need to make your own post. Way back when I asked the estlcam developer about using it for plasma and they specifically told me it’s not well suited. BUT I don’t think they were familiar with plasmac and most of the plasma specific dirty work is handled by the plasmac component dynamically so estlcam might could work just fine. If I remember correctly the estlcam post functionally was kind of limited, worst case you could make your own script in python or something…

The QTPlasmaC gui has a “conversational” tab where you can build basic parts and cut them out skipping the whole cad/cam process. This is super useful for a fab shop for quick parts but probably not so much if your primarily doing art work kind of stuff.

Thanks, I will have to take a look at both. Can’t wait!!!

My little aluminum protection sheet is bending faster than the THC…or the thc isn’t working right. So many things to watch…maybe I need to change some settings, since I didn’t change anything other than voltage offset.

So cool.

If I were still working on a project car, I’d most definitely want CNC plasma. Even without a project car, I still want one.

First though, I really ought to learn to make use of the MIG welder I bought 3 or 4 years ago. I’ve never even finished unpacking the argon gas cylinder I bought for use with it.

Oh man I feel great! That was a long complex project far out of my wheelhouse, but it works fantastic so far. I can not wait to cut some thangs! I need a water table of some sort though. That stuff is nasty and a big fan was not doing squat.

Dude with a welder and a plasma cutter, you are set to make some madness. First, a steak branding iron, then probably 100 more throwing stars…I mean logo’s, then a little fire pit!

I’ve had a blast with my welder. All project requests from the wife had turned into ‘steel projects’ since I got it early last year. Recently she asked for a project and at the end of the request goes, “can you just use wood?”

That’s awesome. You have more pictures of the machine, or is that hush hush for now?

This guy on Twitter had some details