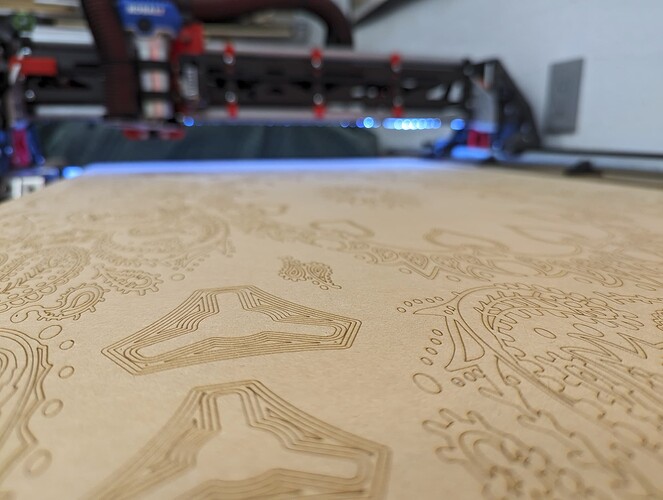

For sure, like a Henna, since it will not last long. I will do it again, though. I like it.

Show off…!

Lol

Very cool!

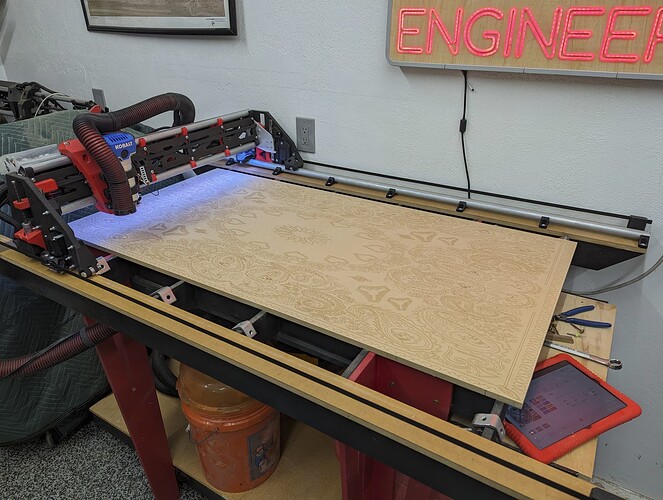

I just need to finish my drawer and the table is done. Playing with the clamps a bit more still as well.

Need to make that into a door or wall art.

I was thinking frosted or etched glass for a door, but yeah, second that thought.

I burned my grid real deep and none of my cuts or sanding have gone though it at all. It took longer to do but will last a lot longer. My logo I didn’t do as deep so it won’t last quite as long. But I figure I can sand over it and just run that part again when I feel like it needs a refresh lol

I like is so much that I’m going to do the little LR3 when I get back home. I did the pen lines on it and that didn’t last long at all. Soon as I sanded screw holes the first time it was practically gone. Don’t have that problem with the laser

@vicious1 , pretty slick. Did you pull that off a deck of cards or create that on your own?

I did a vector search, handkerchief, I edited out the brass knuckles and added the logos.

I can post the link when I get back it is on the shop computer.

So cool

I leave you alone for a few minutes and look at this mess!!! What sort of a can of worms have you just opened?? ![]()

suprised we haven’t seen a picture of your kitchen table top on there getting a tatoo yet.

Not really a tramp stamp… Maybe a chip strip? Or a dust cover?

I came to this thread wondering the same thing (MDF rails longer than 8 feet, but sheets are only 8 feet) and realized that the box stores sell 10’ primed MDF boards up to 5.5" wide. So, if I can figure out the space for it, that’s what I plan on using.

Also TIL Bessel Points. Weird and cool!

I did not know this. Cool.

Airy points as well, depends on what you are going for.

Well, I guess my measurements and my surface spoil board really worked. The laser is still there, yet I cut all the way through.

Now that’s perfection!

I got 2 of these as well to set up my table! Now I just need to find the time to……set up my table!! Doh!!!

A complete newbie here, and to CNC in general. The whole point in my interest in CNC besides the obvious labor savings and exacting repetition, is I’m now a disabled Veteran and can’t stand over a workbench for hours on end carving or cutting hand joinery like I did 40 years ago when I was a Cabinetmaker/Furniture maker. CNC would allow me to replicate many of the things like carving and inlays I used to do entirely by hand. Watching the discussion I like the idea of a drop table. Still, other than removing an entire section of the table, I am wondering if anyone has come up with other ideas, a scissor lift table height adjustment perhaps? Also, this removable center might allow for adding a fourth rotary axis but the stepper-driven ones I’ve seen so far are too small to turn pieces up to 6" in diameter which was on some classic furniture designs. I realize this is usually far beyond the “hobbyist” but if driven slowly, I still believe it doable. 4" would be the norm however. V1 and LRv3 is the most brilliant designs I’ve seen all across the introductory CNC universe, and by FAR the most inexpensive, not cheap, for that would be derogatory, just everything you need and nothing you don’t and giving it out to the community is to be applauded for sure, and I’m sure I echo the thanks of so many you’ve allowed to enter this world of wood/maker technology without selling a child - although I have considered it of my four kids on more than one occasion…grin.

So one of the most clever approaches to this that I have seen, is the one done by Steve, @steved, in which he used the approach of having metal struts for the LowRider to ride on (that are normally used for construction and garage projects, sold in 10 foot sections at Lowe’s or Home Depot, under several brand names, including Unistrut and Superstrut), and instead of cutting off the excess part of the metal struts, the left them sticking out on one end so his LowRider can actually travel right off the end of his table and operate out over mid air, and then he used a couple of (12”?) press screws to add a great Moxon Vise clamp that was made from some extra copies of the torsion box ribs, that he cut and couldn’t use for whatever reason. I think there was some mistake made in how they were cut, and so he didn’t use them for ribs on the table, but rather glued a stack of them together, and use them for this clamping piece. If you check out his build log there are pictures of it. I love the idea.