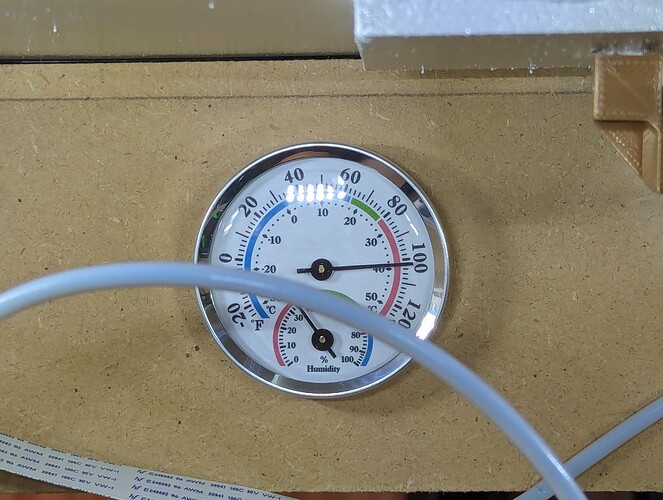

Printing Asa got a little toasty inside the chamber.

Man that’s warm for sure! Hottest mine has gotten with all this ASA/ABS I have been printing is a little over 60°c but I don’t have an active heater

The outer ring is F. That’s only 40C.

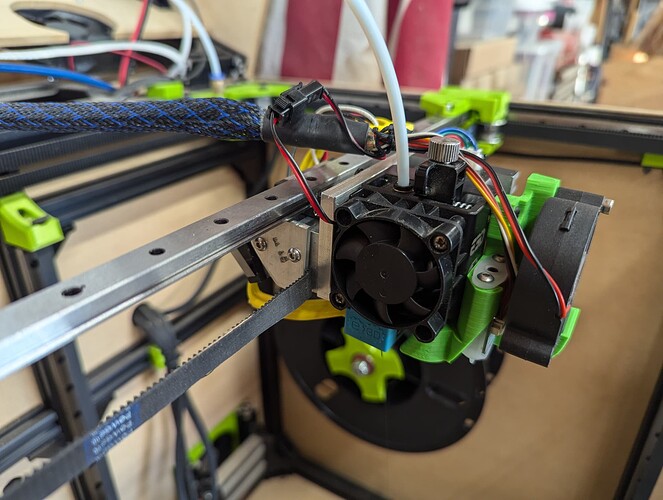

On a side note. I’ve had 4 successful ASA prints without the new core/fan failing. I think I finally have this printer printing ASA.

Which is good. I’m working on a rather large mount for a vertical fan to mount it on a wall in the travel trailer. I’ll need ASA for this print.

![]()

I need to do some serious tuning on this thing.

3.5 hour ASA print. 100 total layers. First layer took 45 minutes of that. I think I’m running that first layer a little slow.

Ordered some new BTT gear for the MP3DPv4. Picked up a new Manta8p, CB2, and 7" screen.

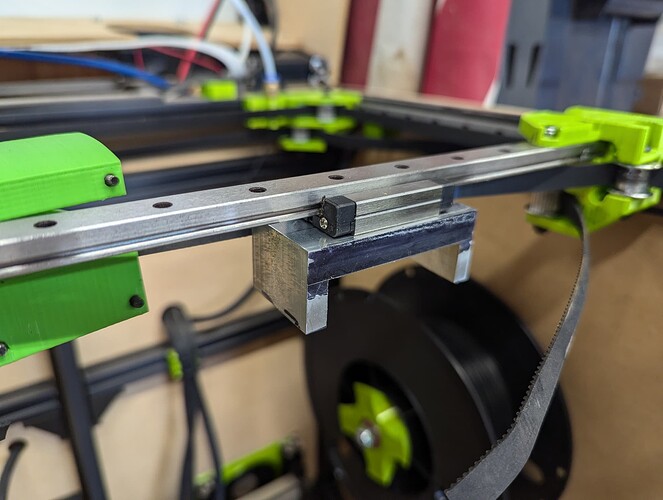

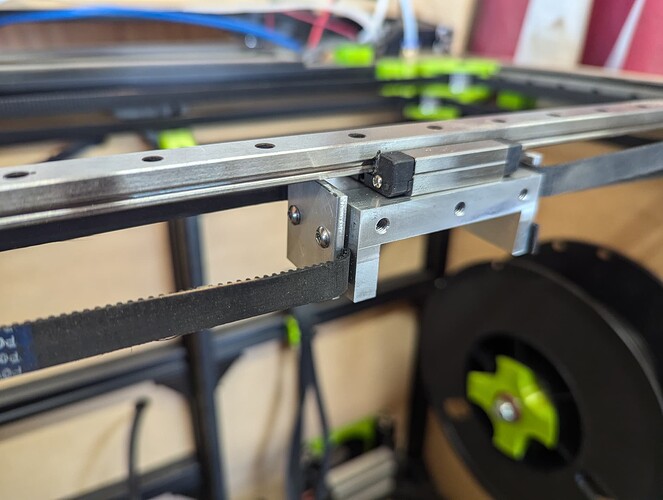

I’m still fighting the X gantry on this machine. For some reason the entire ‘core’ leans forward on the X axis I did find one bolt head stripped. I’ll have to drill it out to replace it.

I’m wondering if the PLA XY pieces got soft while I was trying to print ASA previously and now they’re out of whack.

For some reason. The idler pulleys on my v4 were never level/trammer and it made the belt ride up on the idler pulley on they carrier for the lower belt on the left side. I swapped it out once and then upgraded to the v5 with laser cut instead of milled parts. I had to slightly widen the frame in x, cut down the x rail 1" and resquare and re tighten. That worked because I built it 300x300 to begin with. I’d recommend the upgrade if you are at a point where you have to replace your printed components. The x core is much better on the v5 in my opinion.

smol

I don’t have the time or funds to upgrade to a v5 at this point.

Understandable. The time was the factor I had issue with. I printed the parts with pla in hand and I used a piece of leftover acrylic for the cladding. I had to buy new belts, longer bolts, and a couple idler pulleys. Everything else was reused from the v4. It isn’t a free upgrade. With the v4 compromised, do you need an extra piece printed to get you going?

I still have my original 3d printer. It doesn’t make the best prints, but they’re usable.

Almost changed my mind and just bought a Bambu P1S.

Went back out to the shop and took another look at the v4. I replaced the one screw that had the head strip out. I also noticed both XY blocks were loose. I tilted the core back as far a I could and re-tightened the bolts on the XY blocks to their bearings.

I think I still have a small tilt forward on the gantry, but there is just enough clearance for the Z sensor to clear the height of the filament being extruded by the nozzle.

I think my babysteps is set to just over 5mm now. When I first built the machine with all PLA parts, I think the babysteps was set to around 3 mm. I know there’s a lot of factors that contribute to that value, but that’s what I look at to see how much ‘tilt’ I have.

I have a test print running now.

I have nothing to do on Saturday. I may go take another look at the all aluminum core I started a while back and see if I can figure out where I was on that and resume building it.

I should really be working on the house LEDs as they’re not working again.

Test print done. It looks pretty good. Tomorrow I may try to print one of those articulating dragons again.

Rad! Time to start print tuning.

I need to modify the fan mount or something. There’s a slight tilt to it and the Z probe may hit the ezlxtruded filament. I’m thinking washers under the arms.