Pfffft. That’d be too smart.

On the plus side, the new core finished. I’ll get this installed on Thursday. Maybe I’ll try some of that fancy loctite stuff.

Pfffft. That’d be too smart.

On the plus side, the new core finished. I’ll get this installed on Thursday. Maybe I’ll try some of that fancy loctite stuff.

Well. That print failed. I was afraid it would. I hadn’t replaced the core yet and one of the belts was still stuck on using the end of a zip tie as a wedge.

This morning I finally replaced the core. In the process of doing that, I discovered all the Z belts were loose. That led me down the trail of checking all the other bolts going through plastic on the machine. I don’t know if the heat in the shop is causing the plastic to get soft, so the bolts are loosening, or what. I really need to finish callibrating ASA prints and reprinting all the parts in ASA.

I have a test print running now. It’s looking good. The wife needed the huge print for something she was doing with her students today, so no need to wast filament re-trying it now. Although, she could probably use the things in the future.

All of mine are actually staying good except one that was printed in translucent yellow. Almost every one of those prints failed in different ways, bending and cracking. Horrible stuff. All the rest are in a hot 95-100F garage and holding up pretty well after I replaced the Cores.

Are you running really fast and beating it up? I run 55mm/s with a large nozzle I could see running 70mm/s+ with a small nozzle beating the hell out of it. Part of the reason I am not convinced those speed printers will last long…they are always rebuilding to upgrade so no longevity reports that I know of.

I have the max in S3D set to 60mm/sec, but it rarely runs that fast due to it’s internal algorithms. I’m using a .4 nozzle. I’ve switched over to using Gyroid infill, which isn’t too abrupt on direction changes.

I did have a failed print last night when the one belt came loose again and a large portion of the print was spent dumping filament near the front of the build plate. It was quite spectacular actually.

The inside of my shop hit 108f yesterday and it wasn’t even the hottest day of this year. I do see that the glass temp of PLA is 60c. I know the inside of my cabinet while printing has seen temps close to 50c when working with ASA, but I guess that shouldn’t have caused issues.

I also don’t recall re-tightening anything since I started using this machine. Periodic (monthly?) maintenance should probably be done anyways.

Ok. I’m about over this belt-holder stuff.

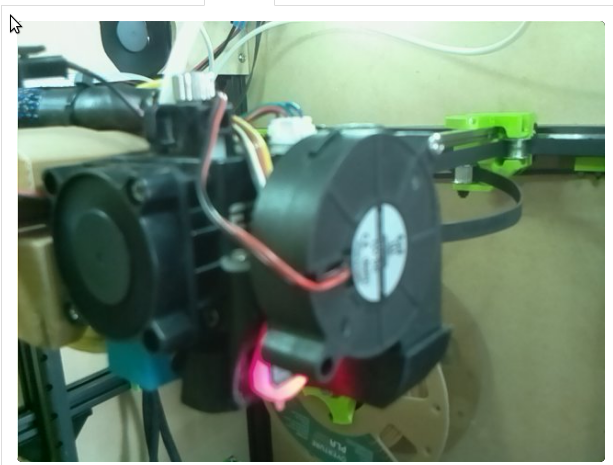

20 minutes left in a 7 hour print and a belt came loose. You can see it loose on the right side of the picture.

I was even watching the print when it let loose, so I killed it. The parts may still be usable. All it had left was printing the top two layers on all 5 parts.

That was with the new core?

Yes. I’m wondering if my belt ‘wedge’ piece is too small. The one I was using only had 3-4 teeth. I just replaced it with a piece that’s closer to an inch long and fills in the void from where it widens all the way out the back of the core.

It was the same belt side/position that pulled out previously.

https://www.printables.com/model/282346-mp3dp-v41/files#preview:file-QB2Wc

Pulled out from Bottom Right belt holding slot?

Bot left.

DAng, back to the drawing board, sorry.

How do you fix? Grub screws (or regular bolts with/without captured nylock nuts to press/crush belt.

Mini tensioner block, larger/tighter turns, or multiple turns like LR3 Belt holders? Triple belt maybe?

Or double belt wrapped still, but with additional wraps of painters/kapton tape? And/or, maybe something else…

Looking at the parts that printed, they printed on a slope.

Could I have had the belts over tensioned? Or is the slope what happened when the one belt first came a little loose?

I have a small print I need to print tomorrow. We’ll see how that one goes.

Part of me is thinking of just gluing the belts in place, but that sure would make repairs expensive.

Happy with your extrusion esteps/calibration, and that slight under extrusion isn’t resulting in looser fit? Would wrap(s) of Kapton/Painter tape help stop Belt pulling through?

Just tugged pretty hard on my belts, they’re not coming out. But then I haven’t done tons of printing with my PETG Core. Just 5-6 teeth on the short Belt bits, I couldn’t get belt to double back on itself.

Am not heating the chamber.

Printed on a slope as there was a skew vertically? Or they were clocked on the bed differently than they were sliced? Have a picture of those skewed parts?

If vertically sloped, that says there is additionally a problem with one or more Z axis steppers/belts.

How flexible is that PETG compared to the PLA? Are they working their way free one jumped tooth at a time?

What happens if you grab a fine point sharpie and mark the belts when you (Re)attach and tension them? Does the alignment between the belt end and loop/segment that secures it change over the span of time? Or does it jump all at once?

Alternately, I wonder if you could be running into some weird resonance when printing. Do you ever notice any significant changes in the way that the corexy motion sound when printing?

Slope… as in, the x-y is shifted slightly towards the back of the machine on each layer. The thickness of the print is the same, so I’m assuming Z is ok. if one of the Z was moving more than the others, I’d expect that corner of the print to be thicker than the rest.

My core is printed in PLA. Someone else mentioned Petg, but it wasn’t me.

I have video of the last failed print. I’ll have to go watch it to see if I can see the small piece of the belt wiggling loose or something. The camera angle is bad for seeing under the printhead.

I tried slowing down my max print speed to 55mm/s . I figured that’s not that big of a difference, but it couldn’t hurt.

It pinches down to a few tenths of a mm over the width of one belt. After printing, that usually means it is the exact width of a belt. The angle is so it is easier to get a doubled up belt into place and then pull it into locking position.

I think this is the most likely. It is super easy to over tension since the tensioners are doubled up, each twist pulls on two belts if you think about it. My belts are extremely loose and the machines are extremely accurate. Belt tension should be about 7lbs. Aza you felt my belts would you describe them as tight? My belts make a barely barely audible pluck. I am sure there are apps to actually check this now, Pretty sure Prusa includes this as a build step.

Screws can easily put hundreds (~400lbs) of pounds of force, adjustments are made by the 1/16 of a turn when tension gets close.

On that same note just pulling on the Z belt tensioners I can overtighten them to the point of stalling the steppers, and that is without the mechanical advantage of a screw.

A drop of superglue is actually pretty easy to break if you need but will hold the belt it. I used it in the first failing core for several days while I made the new one.

Nope built in so you can insert the belt.

Your belts felt surprisingly looser than I expected. Completely changed what I thought was needed. I’ve been over tightening my belts thinking that’s needed to reduce vibrations making their way into the prints as ghosting artifacts.

Coke can based belt tension gauge would be nice.

Or a stacked coin hanging gauge. This could work for every machine.