Right click on the image, save as, works great!

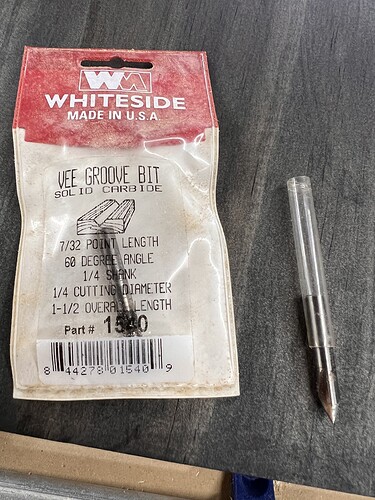

@vicious1 Turns out I have this bit. Would it be better than what I’m using until the new one comes in?? If so suggestions for RPM, feed speed??

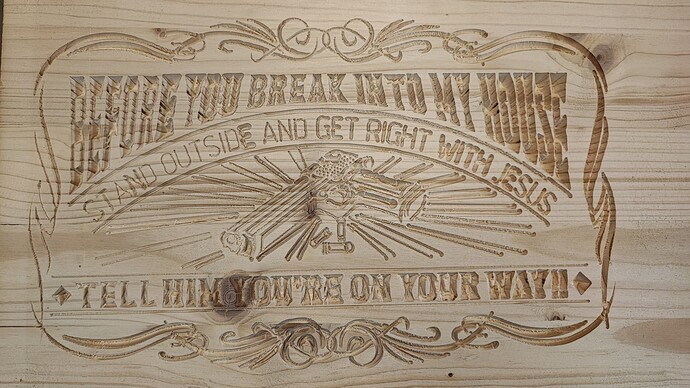

Looks awesome! Nice design!

If you change the setting in youtube that is “not for kids” I can add it to the mpcnc playlist.

Done…Edited all of the ones i have recently posted

Sorry just saw this. Yeah I would think it will be better, slow RPM. I always start a few clicks up and work my way down. Try to go as slow RPM as possible to make carving/chips, not dust. The larger teh diameter the slower the RPM and I use most my single flute 1/8" at the makita’s slowest speed which is about 7k~ish.

According to the spindle paperwork the slowest I should run it is 12,000 and that’s what I ended up running it at. That bit did about the same job as the one before it. I ordered the one you suggested so I will try it next time home and see how it does. Still have several more of these to make. Each one making a little adjustment trying to get better and better. And I guess faster and faster so I can compete with @Tokoloshe lol

The whole thing took me 38 minutes, needs to be cleaned, Z dropped so it looks shitty in a lot of places. You can see the “tell” is still okay, the other text at the bottom is not. Need to fix Z. Hardwood would leave a cleaner cut.

I agree hardwood would come out a lot cleaner than pine. But in my area would triple the cost. Im excited to try the new bit @vicious1 suggested when i get back in town. I think it having a wider cut path will help speed things up quite a bit. I was at around 1hr 30min on the last 2 I did before i left. And then about 10-15 min of brush/x-acto knife work to be real happy with the outcome. a lot of that i think will be taken care of with the wider bit but we will see when im able to test it. I wont be back home until the 15th so long wait till then lol

Here is the whole thing. 5 minutes cleanup since it’s ruined anyway. I might be inclined to do it again some time with Z safe set to 1mm. Might shave off a few minutes. ![]()

I like it!

Sounds familiar, teenagers through young adulthood these days …LOL. You might try prestaining or at least using a pre-stain for the softwood, might ease some of the edge fuzziness.

Wife did a great job on the graphics - first-rate scroll work - VERY nice!!

Ryan, Can you machine the plate you are selling as MDF out of aluminum instead? What would be the additional costs? please contact me directly. What would be the best endmill for cutting 1/4" or 3/8" aluminum? I imagine cutting 1/2" would be pushing it even with a coolant drip feed.

I have cut a few of the XZ plates out of 1/4" aluminum. And I have 2 12"x12" pieces of aluminum here that I was going to try to cut some YZ plates out of for a YouTube video testing the Kobalt router but that has yet to happen LOL. Its defiantly capable of making the cut. Just not going to break any speed records doing it LOL

![]()

JJ is your best bet. I am not set up for that sort of thing right now. Using a new material means going to pick it up (45 minutes away), setting up some test cuts, cutting a lot of aluminum, and you are on your own for tapping all the M3 holes. It is not cheap, and having me do it would not be feasible, I have my hands full with the MDF ones.

Plastic is a much better bet and will save you a ton of money, much less machine time. There is no performance to be gained with aluminum that I can think of.

THIS!!! I agree completely! And I run 1/2" acrylic on both of my machines in a hot Florida garage with no ac

I 3D printed my YZ plates. That was enough to get my machine going to cut my own MDF YZ plates, which are now on my machine. I could now, if I wanted, mill more YZ plates out of aluminum if I wanted to go down that path.

Going this route, although takes more time, etc., is ultimately the cheapest path to getting aluminum YZ plates.

That being said, after sealing the MDF YZ plates, I don’t think there’s really no reason to go Aluminum unless you just think it looks cool. I’m not sure you gain much, performance-wise

But as a bonus, it will make you much better a taking the machine apart and putting it back together ![]()