Yes. You can select each object individually and tell it to machine them in the order they were selected. That will be much faster then grabbing them all at once. Well I guess there is a balance. For a one off just grab them all and let it travel. If you plan on making multiple take the time to do the CAM in order.

You can also speed up your Z considerably. So some test and leave some margin for safety but you can move the Z much faster. It looks like either your depth of cut is too much or your XY speeds are too fast.

You should really take some time to do some smaller sample test cuts to dial that in. Maybe start with a 1/8" flat to take care of most of it before doing the vbit. The last carve I did in pine took a little while but a very quick once over with the wire brush and it was nearly flawless. The newest one is pretty rough, something is a bit too far off.

Oh I love Germany but I don’t think I’d last very long without getting into trouble.

So an artist printmaker - specifically someone who makes lino cuts can’t work to commission or do multiple copies? Why don’t you just do a numbered series (say of 1,000) pieces, sign and number each one as you sell it. Similarly artists accept commissions all the time.

You really just need to see yourself differently - you are an artist who makes things not a maker! ![]()

Do you have a rough guess of where I should start? The one with the video was rough all over. But I was also a thrown in their project. Same sign but wanted to see it carved opposite and I did not adjust settings like I normally would. But you definitely have me wondering what I should have my Z set up at. The carves I have done prior to this always came out real clean. This is a new bit so learning feeds and speeds for sure.

You can, but then you have to found a company that trades with art. So making the art is still a free trade, but selling needs s company. ![]() It’s a tad complicated…

It’s a tad complicated…

There is a setting to optimize toolpaths. It works great if you don’t have a tool change. ![]() If you have a tool change you need to set the order manually for satisfying results.

If you have a tool change you need to set the order manually for satisfying results.

![]() I had an exhibition of paintings in France a few years ago, as an artist (under Australian tax law) I had to earn $40,000 from selling them before I could claim any of the expenses as a deduction. As an art EXPORTER however, well the sky seems to be the limit!!

I had an exhibition of paintings in France a few years ago, as an artist (under Australian tax law) I had to earn $40,000 from selling them before I could claim any of the expenses as a deduction. As an art EXPORTER however, well the sky seems to be the limit!! ![]()

This morning i changed a few things. Slowed feed down from 15mm/s to 12mm/s sped Z up to 10mm/s from 3mm/s Also found machining order menu under Edit that I have never noticed before. When i clicked that I was able to hit optimize like @Tokoloshe suggested. Its still sorta all around but at least its doing a complete letter or carve before it moves on. I took out my 2mm carve bit and just let the V bit do all of it. After optimizing the machining order it wanted like 27 (actual) tool changes and I said no thank you. I can see that i need to change my rapids z settings. its moving faster machining at 10mm/s than it does just picking up to go to the next part. Also I added in a clean up of .2mm hoping that will help it some as well. We shall see shortly! Thanks everyone for the help!

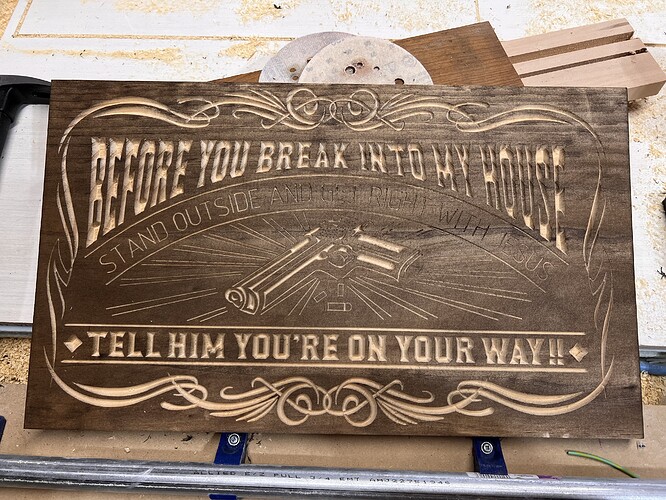

Another sign done after some edits to Estlcam. It still bounces around but it does complete a cut before going to something else so that is MUCH better. Speeding up the Z was a big improvement as well. I took the rapid in main estlcam settings from 250 to 500 but I think I need to go more. I should have calculated it out but I wasn’t awake enough yet lol. Here is the sign from this morning…

That’s after about 5 min with a stiff brush and an X Acto knife. Much better than the first one. I stepped up the cleanup pass too .25mm and slowed down the cleanup speed from 12 mm/s to 10 mm/s. See if it cleans up any better. But I’m much happier with this cut for sure. Thank you to everyone for all the tips and suggestions!!!

I’ll post a finished pic of the first sign soon. Still needs another coat of varnish to be complete

How big are those? I‘d really like to challenge you to a cut the time in half challenge, but I don‘t even have time for my own projects… After the control box maybe. ![]()

They are 11” x 19”. I’m game for the challenge. I’ll have to spend the next 2 weeks researching how to make things faster and still keep quality lol

CNC at it’s finest. I cut a lot of YZ plates, I keep monkeying with things every so often. You can keep shaving time off.

That sign looks amazing.

What type of v bit are you using?

Can you send me the DXF? ![]() I can’t cut, but I can program it at least.

I can’t cut, but I can program it at least. ![]()

SPEED TIGER ICSM Chamfer End Mill - CNC Carving Bits, V Groove, 60 Degree, 1/4"Shank 2"OVL for Wood/Alloy Steels/Hardened Steels-Made in Taiwan(1 Piece, 60 Degree) https://a.co/d/alSJtPl

It wont let me upload the estlcam project. I open the SVG in estlcam under inch and then resize it down to be 11" high. I have my grid in estlcam set up to 25.4 x 25.4 so its easy for me to see inchs lol

Edit…Well i tried to attach the SVG file but i didnt realize it was going to go as an image. If you send me your email address i will email you the SVG and the Estlcam Project.

You can just zip it. ![]()

Too many flutes. You would need slowest RPM possible, with a fast feedrate.

Try a two flute, Amazon.com gives more room for ships to get out of the way an more inline with the RPM and feedrate we use. Even better would be a single flute.

Duh ![]()

D-n-J-1023-Before you Break into my House.zip (120.9 KB)

Tried to do the Estlcam project but the file is too large. For some reason when i try to compress it into a .zip its still the same size file at about 7.5MB

Well crap. i guess i need to go slow the spindle down. Its humming at 24,000RPM right now. I thought i was going to slow at 18,000 and that was causing it to leave stuff. I’ll drop it to 12,000 and see how it goes. Also i will order the one you suggest! Thank you for that!

Also what’s a good “Safe” Z speed? Im running 24v if that matters. I’m set at 12mm/s now but would like to go more if it will be ok and no worry of skipping steps or over heating the driver.