Are you sure?

Doesn’t feel elegant yet, With the wood frame and wire management I might feel otherwise. I am glad it looks that way to you already…I hope to make that better!

Hmmmm, engaging google-fu to investigate my issue further.

I suppose just 200% on an old file is unfair. I will do some proper testing today (super excited to actually).

For me, efficiency is beautiful. Guess that’s it.

I really can’t wait to dig deeper. E3d is showing a PLA volume of 600mm3/min (10mm3/s), then the specs for a volcano are 1800 (30/s)! MirageC is using a volcano…I do have one here that JellyBox gave me. Might finally need to run it!

So I was exceeding the regular heat block recommendations, printing well at 900/m (15/s) and MirageC was hitting around 46/s +++.

Well E3D under rate their hardware, that is awesome…might need a volcano setup now. That means a new fan shroud.

The odd thing is the 24mm/s retract was What I thought would be the limiting factor.

Wow. That is an understatement for what you have accomplished, but Wow. Keep up the great work, I loved following your thought and implementation process. So many people just reach a point they feel challenged and just give up. 3D printing needs more innovation and creativity because it is such a game changing technology.

Luckily, it is super fun almost every step of the way!

Thank you for adding the positivity. As foreign as it feels to me to share “design secrets” and my failures, it did make it a lot more fun. I do enjoy unveiling, a new project, but I do think I liked sharing more. Not sure what this means for future projects yet but I will try to keep updating the progress on this one for a while. I think it will be fun to try and take some of these basic primitive shapes and give them some style and flavor while increasing their functionality, all while sharing what I am doing.

I’m cleaning up my bench, fine-tuning the hardware, and firmware. I hope to share a few more pictures today.

I’ve never felt like a needed another/a new 3d printer. My Prusa is a reliable workhorse. But following this topic makes my thoughts twist and turn to come of with excuses for why I need to build this thing when it’s finished

Only if you want to learn some stuff. I am just about to slice up some test prints to see how that course Z axis works.

Fingers crossed. Last night’s prints look great but I am going to take a harder look now.

The best excuse ever: “Why not? I’m a grown up, and I enjoy it”

Well, that works. I have 8 printers running, my lady asks why are you spending so much time making another one? “Umm, looks fun”…“You’re weird”. AHAHAHAHA I did get a high five when I showed it printing.

Maybe I should try to get more orders on my small-scale business side job. That way I can justify spending money on even more machines… I will never make a living out of it, but I can pay for more machines

Living the dream buddy!! That is all you really need right?!

“why did you get a welder?”, “For the business”…“yeah right you 3D print plastic parts?” “Becuase it looks fun” “Thank you for being honest…and, you’re weird”…HAHAAH we have an amazing relationship

Sure do!!

My wife is a nerd herself, so she can never veto my hobbies - and we are both happy about it. She’s into wool - spinning, weaving, dying, knitting and so on. Right know she is spinning a samoyed+sheep wool combination, funky stuff. I’m trying to make her an motorized spinner, but the electronics keep failing. I should be finishing it up, trying to troubleshoot the driver that acts up…

“Failures” are what we go through in the development of new ideas. Thomas Edison was never ashamed to admit he had thousands of failures before he invented a light bulb filament that worked. At one time he stated he had tried over 6000 different carbonized plant filaments in addition to his metals tests… He had biologists sending him plant samples from all over the world. And then he tried plain old cotton thread. The rest is “illuminated” history.

Oh, now I feel like a quitter! ![]()

As long as I feel like I learned something when it doesn’t work I have no issues moving forward. It’s when no progress is made in any form, I get frustrated.

Running into an issue some of you might have solved.

I am trying to get the bed to stop moving before homing. So if you home to Z max (LR folks) and run a G28 with the BLTouch I can’t get it to move ~10mm further and grinding.

I have changed a few settings but there seems to be something left I am missing.

Turns out Prusa slicer injects it… Works as expected with other slicers.

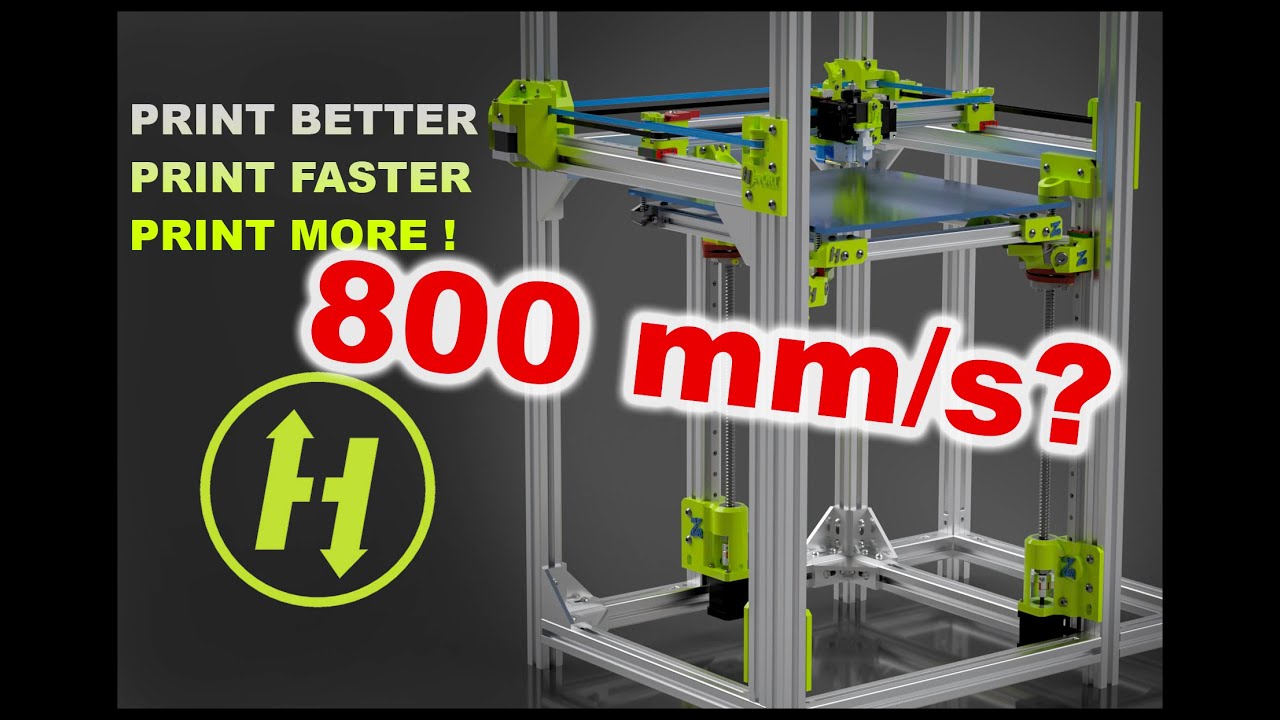

Working on the speed still. Ran into cooling problems more than motion problems. New shroud printing now.

I think the belts are fine. I know people will hate them not holding themselves up, but if you end all prints at your Z max you never notice it. As for resolution, it calibrates for bed leveling just fine typically under 3 iterations (and I am not sure I have the coordinates set right) and it is making tiny corrections. print quality is great…but I am currently doing thick prints. once I get this right I will go thinner.