Buy both? ![]()

Of course! I guess using a regular 0.4mm and the MMU3 will be my daily setup. But I’d love the HF nozzle or a 0.6…

My regular setup is still the 0.6mm carbon nozzle because of all the glow in the dark. If I were you I’d just order a 0.6mm HF carbon nozzle and be done with it forever. You can print one colour officially with the MMU attached (and 0.6mm HF) and with a little rewriting the configuration you can do multicolour as well. Haven’t done that for the MK4S yet, though, so it warns me that it’s using a wrong profile (because I am running a MMU MK4 profile for the 0.6mm multicolour).

Sooner or later they have to add this anyway to not be laughing stock.

Don’t forget that the XL originally came with 0.6 nozzles because they thought with Arachne it would not make a difference.

Then everyone started printing tiny multi colour Nemos and whining about stringing!

For most people, clearly 0.4 is the sweet spot, but for the outliers I’m sure there’s a solution just beyond the next Benchy!

What does this tell us? Nemo can suck it. ![]()

![]()

I will do the opposite of Phillip. He is stubborn and wants to do it his own way. I just want to stay hassle free, keep it simple and follow the book. ![]() Speed is not sooo important. Perhaps a carbon 0.4 nozzle is a compromise.

Speed is not sooo important. Perhaps a carbon 0.4 nozzle is a compromise.

Then definitely go for the High Flow 0.4 Carbon Nozzle. The MMU works fine with it and there are profiles for it, otherwise I see you go back for a HF nozzle later. Using a normal 0.4 does not make sense (in my eyes) except you want to save 2 cents on a multicolour print.

Prusa3d.com here I come ![]()

It seems that my warping problems can be eliminated by setting the bed temperature to 65°C for PLA btw. ![]() I read somewhere that the sensor is crappy and the bed is actually a little lower temperature than it says. Don’t know though, don’t care though.

I read somewhere that the sensor is crappy and the bed is actually a little lower temperature than it says. Don’t know though, don’t care though. ![]() It works now.

It works now.

Because no one did it and I was annoyed at the printer giving me a warning and not starting to print I created 0.6mm and HF0.6mm profiles for the MMU3:

Okay, I helped myself by going through the ini. The new version works with a lot of “inherits=” and then points you to another configuration. If you add those blocks you get 0.6mm for the MMU3 (which I exclusively printed with the last year, so there shouldn’t be any surprises) and the HF0.6 profile for the MMU3 on the MK4S. I can’t promise you that it works though.

In [printer_model:MK4ISMMU3] change variants to 0.4; 0.6; HF0.4; HF0.6

Then add those blocks (you can find the position when searching for “Original Prusa MK4 MMU3 HF0.4 nozzle”, then you add the block after it. The same goes for all four blocks.

[printer:Original Prusa MK4 MMU3 HF0.6 nozzle]

inherits = Original Prusa MK4 MMU3 0.6 nozzle

printer_variant = HF0.6

multimaterial_purging = 240

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_MODEL_MK4IS\nPRINTER_MODEL_MK4MMU3\nPG\nHF_NOZZLE

default_print_profile = 0.25mm SPEED @MK4IS HF0.6

default_filament_profile = "Prusament PLA @HF0.6"

nozzle_high_flow = 1,1,1,1,1

[printer:Original Prusa MK4 MMU3 0.6 nozzle]

inherits = Original Prusa MK4 Input Shaper 0.6 nozzle

printer_model = MK4ISMMU3

multimaterial_purging = 80

printer_variant = 0.6

nozzle_diameter = 0.6,0.6,0.6,0.6,0.6

extruder_colour = #FF8000;#DB5182;#3EC0FF;#FF4F4F;#FBEB7D

single_extruder_multi_material = 1

cooling_tube_retraction = 45

cooling_tube_length = 20

parking_pos_retraction = 84

extra_loading_move = -52

max_layer_height = 0.4,0.4,0.4,0.4,0.4

machine_limits_usage = emit_to_gcode

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_MODEL_MK4IS\nPRINTER_MODEL_MK4MMU3\nPG

retract_length = 0.7,0.7,0.7,0.7,0.7

wipe = 0,0,0,0,0

retract_before_wipe = 80,80,80,80,80

retract_speed = 35,35,35,35,35

deretract_speed = 25,25,25,25,25

retract_length_toolchange = 0,0,0,0,0

start_gcode = M17 ; enable steppers\nM862.1 P[nozzle_diameter] A{((is_extruder_used[0] and filament_abrasive[0]) ? 1 : (is_extruder_used[1] and filament_abrasive[1]) ? 1 : (is_extruder_used[2] and filament_abrasive[2]) ? 1 : (is_extruder_used[3] and filament_abrasive[3]) ? 1 : (is_extruder_used[4] and filament_abrasive[4]) ? 1 : 0)} F{(nozzle_high_flow[0] ? 1 : 0)} ; nozzle check\nM862.3 P "MK4" ; printer model check\nM862.5 P2 ; g-code level check\nM862.6 P "Input shaper" ; FW feature check\nM862.6 P "MMU3" ; FW feature check\nM115 U6.1.2+7894\n\n; setup MMU\nM708 A0x0b X5 ; extra load distance\nM708 A0x0d X140 ; unload feeedrate\nM708 A0x11 X140 ; load feedrate\nM708 A0x14 X20 ; slow feedrate\nM708 A0x1e X12 ; Pulley current to ~200mA\n\nM555 X{(min(print_bed_max[0], first_layer_print_min[0] + 32) - 32)} Y{(max(0, first_layer_print_min[1]) - 4)} W{((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) - ((min(print_bed_max[0], first_layer_print_min[0] + 32) - 32))} H{((first_layer_print_max[1])) - ((max(0, first_layer_print_min[1]) - 4))}\n\nG90 ; use absolute coordinates\nM83 ; extruder relative mode\n\nM140 S[first_layer_bed_temperature] ; set bed temp\nM104 S{((filament_notes[initial_tool]=~/.*HT_MBL10.*/) ? (first_layer_temperature[initial_tool] - 10) : (filament_type[initial_tool] == "PC" or filament_type[initial_tool] == "PA") ? (first_layer_temperature[initial_tool] - 25) : (filament_type[initial_tool] == "FLEX") ? 210 : (filament_type[initial_tool]=~/.*PET.*/) ? 175 : 170)} ; set extruder temp for bed leveling\nM109 R{((filament_notes[initial_tool]=~/.*HT_MBL10.*/) ? (first_layer_temperature[initial_tool] - 10) : (filament_type[initial_tool] == "PC" or filament_type[initial_tool] == "PA") ? (first_layer_temperature[initial_tool] - 25) : (filament_type[initial_tool] == "FLEX") ? 210 : (filament_type[initial_tool]=~/.*PET.*/) ? 175 : 170)} ; wait for temp\n\nM84 E ; turn off E motor\n\nG28 ; home all without mesh bed level\n\nG1 X{10 + 32} Y-4 Z5 F4800\n\nM302 S160 ; lower cold extrusion limit to 160C\n\n{if filament_type[initial_tool]=="FLEX"}\nG1 E-4 F2400 ; retraction\n{else}\nG1 E-2 F2400 ; retraction\n{endif}\n\nM84 E ; turn off E motor\n\nG29 P9 X10 Y-4 W32 H4\n\n{if first_layer_bed_temperature[initial_tool]<=60}M106 S100{endif}\n\nG0 Z40 F10000\n\nM190 S[first_layer_bed_temperature] ; wait for bed temp\n\nM107\n\n;\n; MBL\n;\nM84 E ; turn off E motor\nG29 P1 ; invalidate mbl & probe print area\nG29 P1 X0 Y0 W130 H20 C ; probe near purge place\nG29 P3.2 ; interpolate mbl probes\nG29 P3.13 ; extrapolate mbl outside probe area\nG29 A ; activate mbl\n\n; prepare for purge\nM104 S{first_layer_temperature[initial_tool]}\nG0 X0 Y-4 Z15 F4800 ; move away and ready for the purge\nM109 S{first_layer_temperature[initial_tool]}\n\nG92 E0\nM569 S0 E ; set spreadcycle mode for extruder\n\nT[initial_tool]\nG1 E{parking_pos_retraction + extra_loading_move - 15} F1000 ; load to the nozzle\n\n;\n; Extrude purge line\n;\nG92 E0 ; reset extruder position\nG1 E{(filament_type[initial_tool] == "FLEX" ? 4 : 2)} F2400 ; deretraction after the initial one before nozzle cleaning\nG0 E7 X15 Z0.2 F500 ; purge\nG0 X105 E36 F500 ; purge\nG0 X115 E4 F650 ; purge\nG0 X125 E4 F800 ; purge\nG0 X{125 + 3} Z{0.05} F{8000} ; wipe, move close to the bed\nG0 X{125 + 3 * 2} Z0.2 F{8000} ; wipe, move quickly away from the bed\n\nG92 E0\nM221 S100 ; set flow to 100%

end_gcode = {if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+1, max_print_height)} F720 ; Move print head up{endif}\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X241 Y170 F3600 ; park\n{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+23, max_print_height)} F300 ; Move print head up{endif}\nM702 ; unload the current filament\nG4 ; wait\nM572 S0 ; reset PA\nM593 X T2 F0 ; disable IS\nM593 Y T2 F0 ; disable IS\nM84 X Y E ; disable motors\n; max_layer_z = [max_layer_z]

before_layer_gcode = ;BEFORE_LAYER_CHANGE\nG92 E0.0\n;[layer_z]\nM201 X{interpolate_table(extruded_weight_total, (0,4000), (1400,2500), (10000,2500))} Y{interpolate_table(extruded_weight_total, (0,4000), (1400,2500), (10000,2500))}\n

layer_gcode = ;AFTER_LAYER_CHANGE\n;[layer_z]\n{if ! spiral_vase}M74 W[extruded_weight_total]{endif}\n

default_print_profile = 0.25mm SPEED @MK4IS 0.6

default_filament_profile = "Prusament PLA @PGIS"

[printer:Original Prusa MK4S MMU3 HF0.6 nozzle]

inherits = Original Prusa MK4 MMU3 HF0.6 nozzle

printer_model = MK4SMMU3

printer_variant = HF0.6

multimaterial_purging = 240

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_MODEL_MK4S\nPRINTER_MODEL_MK4SMMU3\nPG\nHF_NOZZLE\nNO_TEMPLATES

start_gcode = M17 ; enable steppers\nM862.1 P[nozzle_diameter] A{((is_extruder_used[0] and filament_abrasive[0]) ? 1 : (is_extruder_used[1] and filament_abrasive[1]) ? 1 : (is_extruder_used[2] and filament_abrasive[2]) ? 1 : (is_extruder_used[3] and filament_abrasive[3]) ? 1 : (is_extruder_used[4] and filament_abrasive[4]) ? 1 : 0)} F{(nozzle_high_flow[0] ? 1 : 0)} ; nozzle check\nM862.3 P "MK4S" ; printer model check\nM862.5 P2 ; g-code level check\nM862.6 P "Input shaper" ; FW feature check\nM862.6 P "MMU3" ; FW feature check\nM115 U6.1.2+7894\n\n; setup MMU\nM708 A0x0b X5 ; extra load distance\nM708 A0x0d X140 ; unload feeedrate\nM708 A0x11 X140 ; load feedrate\nM708 A0x14 X20 ; slow feedrate\nM708 A0x1e X12 ; Pulley current to ~200mA\n\nM555 X{(min(print_bed_max[0], first_layer_print_min[0] + 32) - 32)} Y{(max(0, first_layer_print_min[1]) - 4)} W{((min(print_bed_max[0], max(first_layer_print_min[0] + 32, first_layer_print_max[0])))) - ((min(print_bed_max[0], first_layer_print_min[0] + 32) - 32))} H{((first_layer_print_max[1])) - ((max(0, first_layer_print_min[1]) - 4))}\n\nG90 ; use absolute coordinates\nM83 ; extruder relative mode\n\nM140 S[first_layer_bed_temperature] ; set bed temp\nM104 S{((filament_notes[initial_tool]=~/.*HT_MBL10.*/) ? (first_layer_temperature[initial_tool] - 10) : (filament_type[initial_tool] == "PC" or filament_type[initial_tool] == "PA") ? (first_layer_temperature[initial_tool] - 25) : (filament_type[initial_tool] == "FLEX") ? 210 : (filament_type[initial_tool]=~/.*PET.*/) ? 175 : 170)} ; set extruder temp for bed leveling\nM109 R{((filament_notes[initial_tool]=~/.*HT_MBL10.*/) ? (first_layer_temperature[initial_tool] - 10) : (filament_type[initial_tool] == "PC" or filament_type[initial_tool] == "PA") ? (first_layer_temperature[initial_tool] - 25) : (filament_type[initial_tool] == "FLEX") ? 210 : (filament_type[initial_tool]=~/.*PET.*/) ? 175 : 170)} ; wait for temp\n\nM84 E ; turn off E motor\n\nG28 ; home all without mesh bed level\n\nG1 X{10 + 32} Y-4 Z5 F4800\n\nM302 S160 ; lower cold extrusion limit to 160C\n\n{if filament_type[initial_tool]=="FLEX"}\nG1 E-4 F2400 ; retraction\n{else}\nG1 E-2 F2400 ; retraction\n{endif}\n\nM84 E ; turn off E motor\n\nG29 P9 X10 Y-4 W32 H4\n\n{if first_layer_bed_temperature[initial_tool]<=60}M106 S100{endif}\n\nG0 Z40 F10000\n\nM190 S[first_layer_bed_temperature] ; wait for bed temp\n\nM107\n\n;\n; MBL\n;\nM84 E ; turn off E motor\nG29 P1 ; invalidate mbl & probe print area\nG29 P1 X0 Y0 W130 H20 C ; probe near purge place\nG29 P3.2 ; interpolate mbl probes\nG29 P3.13 ; extrapolate mbl outside probe area\nG29 A ; activate mbl\n\n; prepare for purge\nM104 S{first_layer_temperature[initial_tool]}\nG0 X0 Y-4 Z15 F4800 ; move away and ready for the purge\nM109 S{first_layer_temperature[initial_tool]}\n\nG92 E0\nM569 S0 E ; set spreadcycle mode for extruder\n\nT[initial_tool]\nG1 E{parking_pos_retraction + extra_loading_move - 15} F1000 ; load to the nozzle\n\n;\n; Extrude purge line\n;\nG92 E0 ; reset extruder position\nG1 E{(filament_type[initial_tool] == "FLEX" ? 4 : 2)} F2400 ; deretraction after the initial one before nozzle cleaning\nG0 E7 X15 Z0.2 F500 ; purge\nG0 X105 E36 F500 ; purge\nG0 X115 E4 F650 ; purge\nG0 X125 E4 F800 ; purge\nG0 X{125 + 3} Z{0.05} F{8000} ; wipe, move close to the bed\nG0 X{125 + 3 * 2} Z0.2 F{8000} ; wipe, move quickly away from the bed\n\nG92 E0\nM221 S100 ; set flow to 100%

end_gcode = {if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+1, max_print_height)} F720 ; Move print head up{endif}\nM104 S0 ; turn off temperature\nM140 S0 ; turn off heatbed\nM107 ; turn off fan\nG1 X241 Y170 F3600 ; park\n{if layer_z < max_print_height}G1 Z{z_offset+min(layer_z+23, max_print_height)} F300 ; Move print head up{endif}\nM702 ; unload the current filament\nG4 ; wait\nM572 S0 ; reset PA\nM593 X T2 F0 ; disable IS\nM593 Y T2 F0 ; disable IS\nM84 X Y E ; disable motors\n; max_layer_z = [max_layer_z]

default_print_profile = 0.25mm SPEED @MK4S HF0.6

default_filament_profile = "Prusament PLA @HF0.6"

nozzle_high_flow = 1,1,1,1,1

[printer:Original Prusa MK4S MMU3 0.6 nozzle]

inherits = Original Prusa MK4S MMU3 HF0.6 nozzle; *MK4S_LFNOZZLE*

printer_variant = 0.6

multimaterial_purging = 80

printer_notes = Don't remove the following keywords! These keywords are used in the "compatible printer" condition of the print and filament profiles to link the particular print and filament profiles to this printer profile.\nPRINTER_MODEL_MK4S\nPRINTER_MODEL_MK4SMMU3\nPG\nNO_TEMPLATES

default_print_profile = 0.25mm SPEED @MK4S 0.6

default_filament_profile = "Prusament PLA @MK4S"

nozzle_high_flow = 0,0,0,0,0

I just copied my entry from over there. No idea why it makes parts of the code colourful here. ![]()

Impressive! That’s what I said - you ARE stubborn! And it sure pays off ![]()

Are you thinking of the obXidian nozzle? Can’t find a carbon nozzle, only brazz.

Yeah, that’s the name. ![]() Original Prusa 3D-Drucker direkt von Josef Prusa

Original Prusa 3D-Drucker direkt von Josef Prusa

Do you think the hackerboard is really necessary? Can’t actually think of any use cases. As said already - I just want something that works ![]()

Didn’t order the board. Though it’s cool, I am not REALLY Hackerman.

Eeek! It’s expensive! More than I thought…

Btw: If you let them print the parts you can just throw in another 30€ for the fully assembled MMU. I printed the parts myself though.

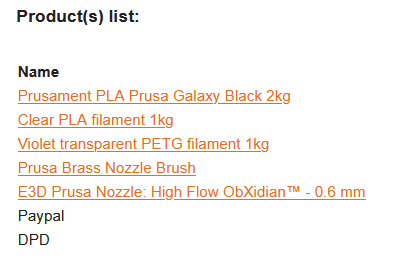

I carved… I can’t live wihout a 0.6mm obXidian HF nozzle any longer. ![]() Also, there is a sale on a few of their other manufacturer’s filament. I mean, 18€ for 1kg of transparent PLA and violet transparent PETG? You can always use PETG…

Also, there is a sale on a few of their other manufacturer’s filament. I mean, 18€ for 1kg of transparent PLA and violet transparent PETG? You can always use PETG… ![]()

Anyone wants to buy a 0.6mm obXidian nozzel? Non-high flow? ![]()