Wth! What do they think input shaper will do???

Burn my house down and sleep with my wife… It definitely has got the sex appeal needed. It’s so incredibly fast. I still had the low speeds of TPU in mind and the MK4 goes neoooooooooow. ![]()

@vicious1 I did learn that printers are a tad more complicated than a CNC, but I still think that the LR3 is the more impressive design, considering it looks awesome and only needs two types of screws (okay, four, but those little ones don’t count). Especially this is really appreciated. ![]()

MK4 goes neeeeeeeeeoooooooooow, printing some eyepatches designed by some old guy from Australia (cough@bitingmidgecough). Thanks for the design! Whole printbed full takes 2:20h.

![]() Just be careful with the hot water when you bend them!

Just be careful with the hot water when you bend them!

Going to let my wife do it, she’s got asbestos hands… ![]()

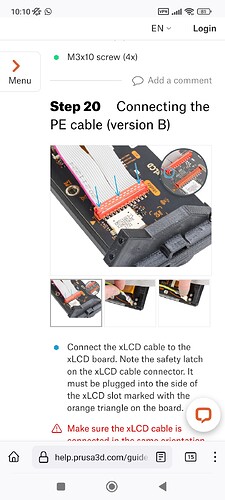

Now a negative: I’ve got a problem with the screen, as described by other people in this topic: Mk4 screen goes blank after some time – Assembly and first prints troubleshooting – Prusa3D Forum

The screen just goes blank at random times, distorts colours or shows weird stuf, some speculate it’s electrical interference because it works if the screen’s cable is ran somewhere else, but there is no official confirmation of what the cause is. The prints still finish, but kind of stupid. ![]()

Go straight to customer support! Presumably there are 20,000 + Mk4’s in the wild by now, so there’s probably a solution!

Yeah, I waited over an hour for the live chat and then decided to call it a night and write an e-mail. It seems to be happening with assembled printers as well and none of them have been given a satisfying answer. Some printers were exchanged, some LCDs, but the swaps of the boards (buddy/LCD) did not solve the problem. Boo! Will tell you if I get an update. ![]()

Yeah, that sounds like textbook noise/EMI issues. Fine most of the time and then something unlucky happens and the LCD is unable to recover cleanly. If anyone was wondering why I was making such a big deal about the routing and signal integrity comments on the 6-pack and pendant threads, this is a pretty good example of how things can go wrong. Features that probably worked 100% in the lab but keel over randomly out in the field with almost no possible way to reliably recreate the issue in order to debug it. Rough.

@Tokoloshe , what about wrapping the cable in copper foil and grounding it? But you should probably wait until you hear back from them before you start doing something that could possibly void your warranty.

Could be worth a try, although I’ve seldom had good luck with that approach. Most foils are so thin that they only really help with particularly high frequencies. Braid might be better, but significantly more expensive to muck around with. Connecting the foil/braid to a chassis earth is also probably better, if the circuit ground is floated from it.

Can also try clip-on or solid cable ferrites as a rough test.

I really hate trying to track down stuff like this without a clear cause. It’s so much easier when you can identify the noise source and then test changes against that directly.

So there’s an advantage to living on the opposite side of the world! Great service from the midnight to dawn shift! ![]()

Would a normal braid already help? I’ve got some lying around.

Not sure what you mean by ‘normal braid’, sorry?

If it’s something like hollow copper braid like the stuff sometimes used for ground straps in enclosures then maybe.

This: https://www.amazon.de/gp/aw/d/B073YL3HMC

Maybe I could wrap it in tinfoil and then use the braid over it?

Ah, that’s PET so non-conductive. It won’t do anything, sadly.

You can try with the tinfoil, that’s pretty close to what Gato suggested above. I’ve personally not had good luck with thin foil shields because if the shield is thinner than a couple of skin depths of the frequency that’s being shielded from, it essentially gets radiated back out the other side, which can potentially even make the situation worse by increasing the surface area of the cable for E-field coupling.

Usually shielding is either conductive braid for lower frequencies, foil for higher frequencies or, ideally, a combination of both.

If you can find a clip-on ferrite (or salvage a ferrite out of an existing cable like an old VGA cable etc.) then you can always try looping that through.

Out of interest, what does the cable look like between the screen and the printer?

Prusa should see this! Wow, I’ll never stop being amazed by all the knowledge this forum gathers.

I’m going straight to my electronics salvage bin to find some ferrite cores. I only lack the printer kit though… Prusa - do you hear??

To be clear, this is all just a ‘hail mary’ kind of attempt, I doubt it’ll actually do much. Shielding and ferrites are normally a ‘last resort’ tool to fix other faults in a design.

I think it’s probably best to assume that the people at Prusa are competent enough that if it were a simple fix, they would have implemented it and this is just a rough ‘maybe it’ll help’ kinda thing. Then again, I guess that logic is circular because if an issue like this were showing up, I’d have also assumed they would have sorted it already.