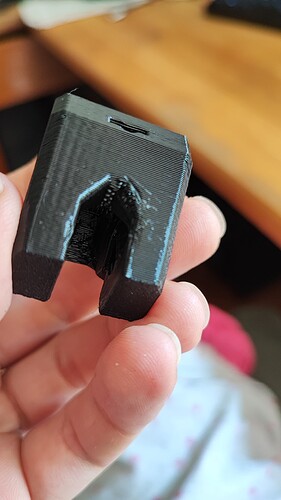

Ghosting and bad overhangs. ![]() Still works, but doesn’t look good.

Still works, but doesn’t look good.

Is that a part that came in the kit or you printed that? I’ve seen some of your prints and don’t remember any of them looking like that lol

Came with the kit (the E6 gives it away). ![]() As long as it works it’s fine, but the ghosting is worse than on my first Primo core. Those parts won’t be seen later, the orange ones look better.

As long as it works it’s fine, but the ghosting is worse than on my first Primo core. Those parts won’t be seen later, the orange ones look better.

The frame feels great and sturdy. And yes, my desk is a mess.

They must be running at beyond max capacity in the print farm.

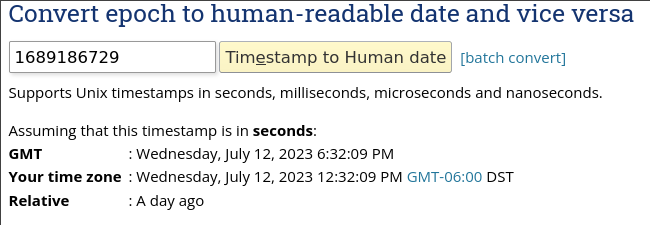

You bastards… “Order 1689186729 confirmed”

My FDM printer is shit anyway, and I’m not going to fight with it to make it useful.

Good for you. That should be a lot of fun.

My mk3s had a big dent/hole in the packaging. It actually bent a few pins on the back of the main pcb. Everything worked as it should, but annoying that shipping is so rough! Support didn’t have anytime else to say than have me report back of there were any actual issues…

There is no loctite for the grubscrews. I am sweating. ![]()

Production of the Mk3 was rumoured to be around 10,000 units shipped per month - add Mk4, Mini and XL and divide by 500 printers in the farm - they are busy little gadgets!

It will come as no surprise that I don’t like nasty looking prints even if they aren’t seen, but the other side of that coin is that this is quite an endorsement for the “print it fast and strong” school. With the number of units shipping they must be pretty confident of the serviceability of those parts.

I guess we just have to think of it as art! ![]()

![]()

I recently bought a bambu p1p. Printed the LR3 core in 7.5 hours / 250 mm/s 0.2 layer height

not sure what that line is (its on a dresser, wondering if it starts rocking the whole thing at that point) but its loads faster and better quality than my first 3d printer, the wanhao duplicator I3, which the bambu p1p is replacing.

I’ve never had a prusa or any other brand of printer so I can’t compare. But I’m loving it.

I printed my core in five times that time! ![]()

Has anyone done any testing on the strength of PLA with that sort of speed? I suspect it is all a bit academic but it would be nice to know.

There are so many cores with a slight layer shift (mine included) that I started to wonder if it was part of the design, but since they all occur at different heights I suspect not!

I thought the Core XY printers would be immune from that but apparently not.

Start em young!

I just thought about that this morning. I grew up without a microware for a long time, people still used handsaws because cordless was not an option…growing up in today’s world must be so very different.

I also have a Johanna. While her bigger brother should in theory be better suited as an assistant, he’s way too independent and impatient to help his father out. His sister on yhe other hand, loves to help out and be in a two-some company, so I think she’ll be more interested.

Buuut, now I’m starting to grow impatient here! This is the last shipping day of late 12th of april batch, and still no sign of life from Prusa. ![]()

Our kids are kind of blased with robotics and technical stuff. Both their mum and me like to build and make things, so they grow up thinking that it’s perfectly normal that their parents renovates old cabins, builds robots and weaves nice pillows and textiles.

I think about some of the stuff I used to do and wonder where the knowledge and confidence to do it came from.

Mostly it was because we pulled stuff apart from a very early age to see if we could put it back together again, and mostly we could.

Our “youtube” was Popular Mechanics magazine and the like, but I still shake my head at the thought of a 16 year old me shaving the warped head of the car using valve grinding paste and a sheet of glass and a few (what seemed like thousand) hours of elbow grease.

I don’t understand how any of what we did was possible with almost no tools or instruction .

Carpenter builders today take truck and trailer loads of gear to building sites, my father in law used to take all his tools in a Gladstone bag (on the bus) to do the same job.

Make some side panels for it. Should stiffen it up quite a bit.

There often wasn’t a question in there. It was a matter of survival. You damn well better put it back together again! Usually with the same rusty, pitted, stripped out philips screwdriver you found in the empty lot and janky Boy Scouts pocket knife that you took it apart with. Lord help you if you broke a solder connection. If you were lucky, you might have access to electrical tape, but that was iffy, at best.

Pro tip: If you drop a mushroom with tomatoe sauce on the sleeping baby wearing your wife’s favourite baby-pants and wash it out with greasy hands from lubricating the rods, you are going to have a bad time. ![]()