I agree with the advice to not try printing that standing up like that.

You’re probably aware that Tom Myers (@tgm022861) part shown there is LR2 as opposed to LR3.

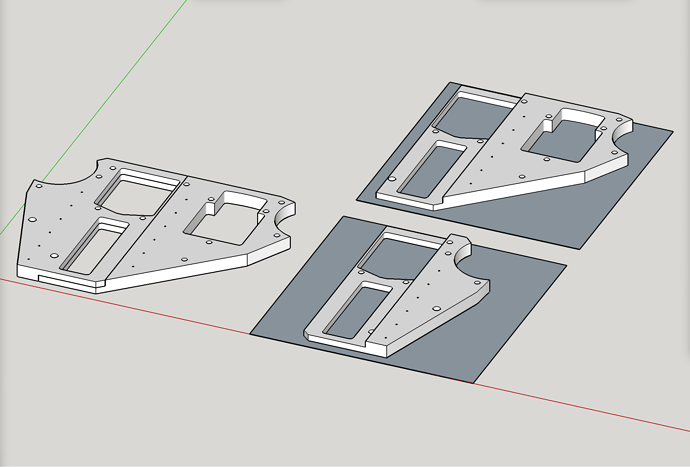

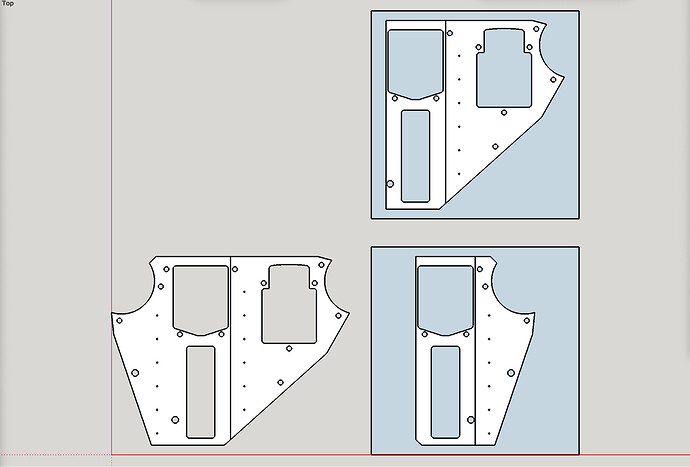

I’ve quickly worked up an approach to splitting the YZ plate for printing as two pieces. This is based on the approach shown by Tom, but it seeks to have all the cutouts completely contained as opposed to a slice running right through any of them.

YZ Plate - split for printing.zip (119.2 KB)

The illustrations show how they would fit on a 220x220 print bed.