Ooohh I see, I nearly snapped off the one on the first side build, got my way for the second one and it was easier.

I think the problem is more of a built method than a design issue…I’ve got thick hands and fingers ![]()

Should work. Go to the wifi network selection, sign into FluidNC, pass 12345678. From the instructions. you might have to then go the the web page at 192.168.0.1

I flash all jackpots before they leave, yes.

Got everything wired and turned on the board, it looks like it works ![]() , connected to FluidNC and loaded through the URL, Tried moving Z, at it showed like trying to go opposite way, turned it off, then tried to home X axis and it moves like under some trembling and not smooth

, connected to FluidNC and loaded through the URL, Tried moving Z, at it showed like trying to go opposite way, turned it off, then tried to home X axis and it moves like under some trembling and not smooth ![]() and then FluidNC throws an alarm message on the end-stop once it triggers.

and then FluidNC throws an alarm message on the end-stop once it triggers.

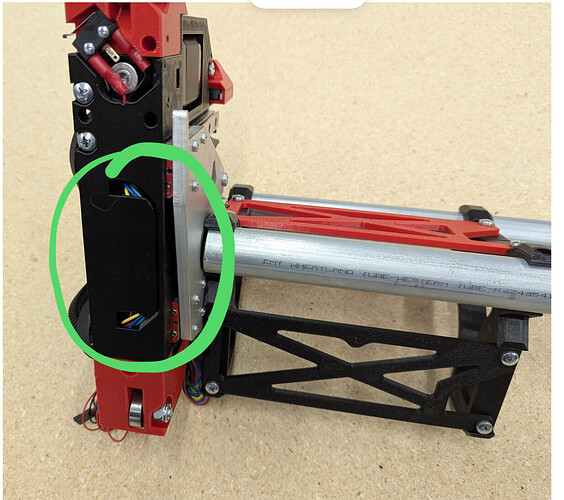

So I’d like to double check my steppers wiring is fine in the first place…anyone can help to check if my steppers terminals match the connections on the board ? Just in case I need to swap some wires which stepperonline advices of on their site.

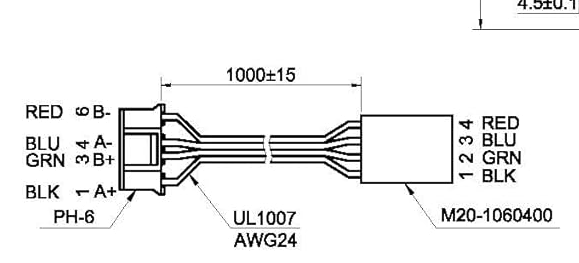

Here’s the info on my motors:

Stepperonline motors

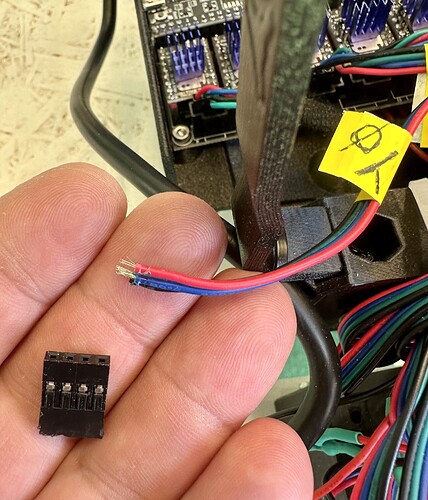

Here’s how I have them at the moment.

Use $limits in the terminal to check all your connections first. Then you can home each axis and trigger the switch by hand to see if that stepper stops.

Is this only when homing? does it move the correct direction when you try to jog? If not, see which side (or both) that is going the wrong way, disconnect power and flip the motor plug on the jackpot.

This sounds like a bad motor connection somewhere. Check your wiring all the way back to the motor. Make sure you dont have a wire that has slipped in a connector.

I’ll do that first thing.

Thanks

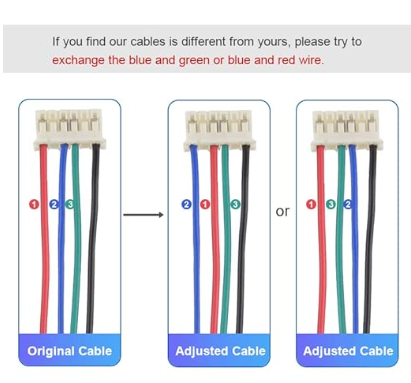

Only tried to jog it…regarding the connectors I have a weird instruction from Steppermotors which I don’t fully understand…Why should I need to do this cable change ? I’m using their extensions with same colors all the way from the motors ![]()

Some steppers are wired AABB and others are wired ABAB. We need AABB and I have seen past threads where people had to swap the middle 2 wires. I am not sure if their extensions do this for you but worth double checking for sure.

Thanks, that means I need to swap them as the extenders stay as ABAB…so need to swap green and blue to get AABB.

That will probably cure some of the problems.

![]()

The only reason to swap wires is if when you try to move it sounds like a very nasty grinding instead of moving. If they move, swapping wires is not needed.

That is what sort of happens…I’ll try on X axis and see if that sorts the erratic moving…mine doesn’t slide at the moment, just shakes madly while trying to move…so I guess I need to change the wires.

I’ll come back as soon as I can try it.

Thanks

Awesome!!! ![]()

![]()

I only have a question now…is X+ supposed to move the core towards the endstop side? And is Y+ supposed to run towards the Y endstops side?

Want to make sure it’s running the right way ![]()

BTW how is the machine supposed to know the limits on the non endstop ends?

Thanks

X+ should move away from the endstop

Y+ should also move away from the endstops. If you are standing at the front of the machine looking at the core Y+ should move away from you and X+ should move to the right

It doesn’t. When you set up your CAM for your jobs you make sure to not go beyond what the machine can move to. As you get used to it and learn more it is quite easy to stay inside of your limits.

Very helpful. Thanks

No problem.

To change the direction of an axis. Power down the board and unplug the stepper, flip the plug 180° and plug it back in.

I have one of those 3d printer belt tension tools, it shows info on mm/inch, can I use it in some way to achieve the desired tensioned on the LR4 ? What should I expect it to be like in terms of tension ?

Or do I just go for an initial guess ?

Cheers,

If i can ruin things i do it ![]()

![]() , now crimping time, which i hate

, now crimping time, which i hate ![]() , at least it was only one.

, at least it was only one.

I’ve managed to test all motors and make them run on the right direction.

X and Z work fine and enstops work too…now only need to test Y. Let’s see if I can do it tonight after work.

I’ll change my belts for nylon reinforced ones, the ones I had at home are too flexible when under hot days !!!

Thanks everyone for your help !!!

![]()

![]()

![]()

![]()