Also, I’d love to use estlcam, but it’s not available for Mac, and I don’t have a Windows computer anymore.

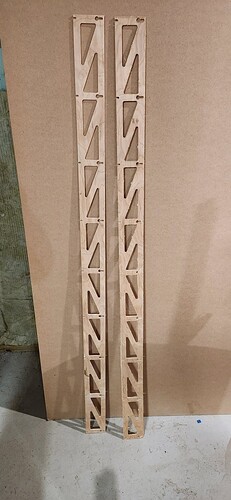

Two down, one to go!

I got the first strut really cleaned up and the second one cut last night. For the third/face strut, I may try the custom version; That file is currently in progress.

QUESTION: Has anyone else found the screw slots to be tight? The keyholes fit a 5mm machine screw just fine, but the open-ended slots not so much.

I realized what’s going on with the length error: I designed the strut at 1450mm, not 57" (close, but not exact). 1450mm is actually 57.08661 inches, where 57+1/16 is 57.0625. Even without any machine calibration, that’s only an error of .024" over a 57" distance, and that doesn’t account for error in my tape measure skills!

You might find this thread interesting. (I did)

I sure did. I found the keyholes did not fit over the screw heads and the slots both top and bottom were too tight. I did a little finish work on each and every one to get them to work. I chalked it up to it being my first actual cuts and use along with the machine not being dialed in yet.

Great stuff, thanks! It looks like it’s leading me down another deep rabbithole of good stuff to try. My laptop is an Intel-based MacBook Pro 13"

For intel-based Macs then Bootcamp may be a better choice. You could also use a virtual machine, since the underlying architecture works, it would probably have better performance than any of the other options that are directed at the ARM architecture. Good luck!

Good suggestions. I use VirtualBox a bit for work, but with Ubuntu Linux OS. A few years ago I used VirtualBox on the Mac with Windows10, but those old VM images no longer boot, and I can’t find a free Windows disk image like they used to provide. I guess I could actually buy a copy of Windows… ![]()

One thing I love about the Mac (and Linux) is that I rarely have to reboot, so I tend to have a lot of open apps and windows/tabs. Rebooting to get into Windows doesn’t sound too pleasant, because it would interrupt my workflow on anything else I’m using the Mac for.

Sounds like a VM solution may be the way to go…

hello @beerreason just seeing if you had any updates. Have you got to use your machine yet?? I am still stuck in the finalizing steps, getting the wiring and dust collection completed to be actually done with building and designing this monstrosity.

Hey – thanks for checking in. See this thread for something I’ve been playing around with! Anybody creating architectural moldings?

My machine still doesn’t have permanent struts, no real table. I had hoped maybe to cut out a torsion box table last weekend, but life has turned again (not that I’m walking away from the LR3 this time, though). Find out why here Message #2006 by beerreason – #Random !

Well I definitely understand that! The puppy in my first posts was my version of the same process you have went through I lost Otis and it took almost a year until my wife surprised me with a puppy. I can tell you like the german shepards and I am the same way with basset hounds.

Best of luck with the puppy.

Well, crap. I think I just answered a 3D printing question I’ve had for a while. If the PLA filament gets brittle sitting in ambient room air, what’s to keep the printed objects from getting brittle?

Answer: NOTHING. My LR3 basically just fell apart. Nearly every brace is cracked where it grips the conduit, and the gantry fell to the table. Fortunately, I had a 1/4” bit in the router, and it wasn’t even spinning, so no collateral damage. But now I’m printing a new set of gantry braces and I’m out of commission for a while.

Anyone else had this happen? How to prevent it? I had used Inland PLA+ (before reading that I should use plain PLA). Now I’m reprinting with some of the freshest Inland PLA (plain) that I have on hand. It’s gonna be a while.

I had a roll of PLA+ that at first glance printed beautifully, but eventually everything printed with it delaminated due to abysmal long-term adhesion in Z layers.

I did not use that filament for any functional parts because PLA is better for our application.

Do you have pictures of your failed parts?

Are the failures fractures not along Z layer lines?

No, not along Z layer lines. It’s possible that I over-tensioned my bolts that clamp the conduit, but it’s essentially the thin part of the “jaw” just past the bolt (on the conduit side of the bolt) where these have snapped.

I was air-testing my gcode with no material and the router not spinning, and I’m not sure whether it broke first, causing the gantry to fall, or maybe the gcode was bad, causing it to drive the bit into the table, over-stressing the gantry braces, thus the failure. Either way, it’s new braces for me and a good portion of the weekend down the drain.

And OF COURSE it’s right when I have a project for a friend’s birthday next weekend that I’m trying to get done… ![]()

I’ll shoot some photos and post this evening.

Every time. If you were just messing around with no deadline at all, it would all go perfectly smooth ![]()

In a way, I guess I’ve (re)learned a lesson about painting yourself into a corner, schedule-wise. I’ve been working on modeling the object for the past few days, got my toolpaths created in Fusion360, everything ready to go to start cutting as soon as I quit work (from home) today. Didn’t even occur to me that the machine might break or die.

In 20/20 hindsight, if I had at least tested the machine a few days ago and had this happen, I could’ve been printing anything I needed on the side while I was doing “real” work this week. Kinda kicking myself now for not planning for contingencies, for not thinking enough ahead, all that stuff.

Here’s where they broke, almost uniformly.

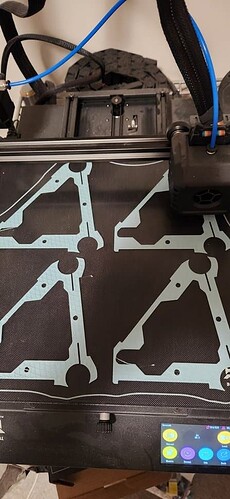

And the Biqu B1 SE Plus hard at work

And the #1 reason I haven’t been doing much CNC stuff these past 4 months. She just turned 6 months old this week.

A few thoughts occur to me.

- This might have been caused by a brain fart/memory lapse. When I last used my LR3 (in April), I was cutting the struts and was about to install them. It’s possible that I had loosened all these brace bolts in preparation for installing the struts, and then got sidetracked with the new dog. Then today I tried to run a gcode program, and the thing shook itself loose, causing those clamps to snap. I’m not sure, but there’s a nagging possible memory to that effect.

- CA glue probably wouldn’t be enough to hold these parts back together.

- Just as a test, I’m wondering if an army of zip ties would hold it enough for me to at least dry-run the gcode while I’m printing new braces. It’s the outer half of each clamp that’s broken, so maybe I could tie the conduit back against the braces, where the inner half of the clamps is still intact. Hey, it’s worth a shot. I’ve got nothing but dead time on my hands right now.

Speak now if you think this is insane. Otherwise, I’ll post an update later, using my remaining fingers.

I’ve seen this before from overtightened braces. And unless I am misunderstanding your idea for the zipties, I don’t think it will work since the core bearings wont be able to ride over the zipties.

Crap, you’re right.