Those might make for some cool stickers.

Thank you, Ryan. Don’t mind at all sharing the files… included are svg, dxf, and LB files. Please let me know if I missed something…

– David

V1Engineering-coins.zip (163.7 KB)

You are the best, thank you! Just got an email with a coupon code for some stickers…kismet.

Or a front and rear Tshirt logo… Top one over chest pocket, and the left one blown up on back

Ohhhhh good idea.

Speaking of “good ideas” – an observation…

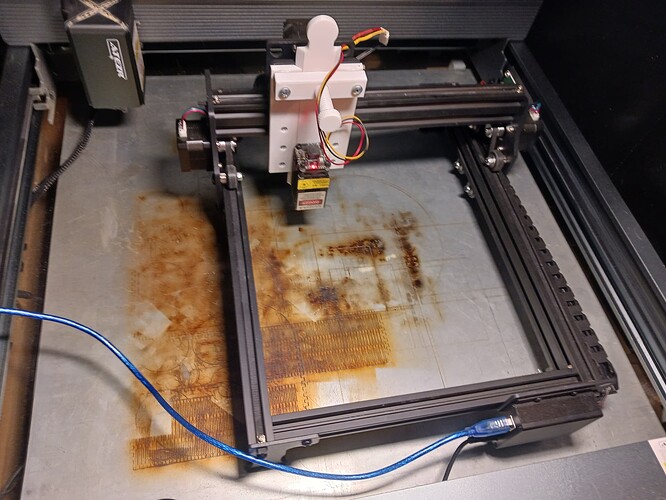

Running out of flat surfaces to put machines on – and still wanting on occasion to use my low-power lasers to do engraving on ceramic tiles and such – I happened to think (in the middle of the night… as crazy ideas often do nowadays ![]() ) to see if the Atezr laser’s large workspace (430mm x 430mm) might possibly double for my $79 Cenoz/Banggood 2.3W laser machine. Hey, no sweat! There’s plenty of room to install and remove the smaller machine…

) to see if the Atezr laser’s large workspace (430mm x 430mm) might possibly double for my $79 Cenoz/Banggood 2.3W laser machine. Hey, no sweat! There’s plenty of room to install and remove the smaller machine…

Not only that, the enclosure’s exhaust fan and air assist are also available and can be operated separately… apart from the Atezr machine.

Not a real biggie, of course, but a surprisingly good idea for an old man to think of in the middle of the night (when not entertaining company, obviously!)… ![]()

– David

laser inception

Are you going to get one of their 35W laser engravers when it comes out? Looks like it uses 6 - 6W diode lasers. Also looks like they currently have their P20 Plus at a little more discount of $850. I am sure considering getting one of these. The P20 Plus is probably all I need. I use to think I needed a CO2 laser, but these lighter weight more portable power diode lasers seem like a very good alternative to those.

Atezr V35 PLUS 35W Laser Engraver with KA and KR Pro Set [Pre-sale]

Hey, Dave! With my current lack of motivation and focus, it’d be hard to justify the 35W machine right now. The 20W machine is a fantastic machine but I’m really not pushing it to do anything particularly noteworthy… and it’s all I need for now. If you’re in the market for one, though, I’d certainly recommend it – and the enclosure! – as there are some pretty nice discounts/bundles right now. While certainly lighter and more portable than most CO2 laser machines, it and the requisite accessories are still pretty bulky and heavy by comparison to the many 2020/2040 extrusion-based laser engravers out there right now. But the beefier construction seems to be the trend now… and other vendors seem to be following suit with their latest offerings.

I’ve gotten side-tracked a bit by several other projects lately… turning a couple of EOL’d Chromebooks into real Ubuntu 20.04 laptops (for LB compatibility), getting my CO2 laser running under Lightburn and VirtualHere control (it’s far more fun and useful now), playing with RPi camera, etc. But I’m hoping that I’ll be able to get back to playing with my lasers soon. I’ve got a couple of things in mind I’d like to try…

– David

Interesting. I’m hoping this diode power race drives CO2 prices down because I’d really like to eventually buy a CO2 to cut clear/transparent acrylic. I just can’t justify the cost right now. ![]()

Another cool feature of the latest Lightburn is the QR feature, you could burn that on the back with any information you wanted to have in the QR code. I have tried it and it works great You can scan it with a phone that has that capability to read QR codes. It is under tools.

Hey, Dave. I’m gonna amend my previous “I can’t justify it” answer to your question. Atezr did indeed come out with the P35 and essentially it was the same machine as the P20 I have… just a more powerful laser module. I really couldn’t justify it on increased power alone… the 20W P20 machine really was a nice machine.

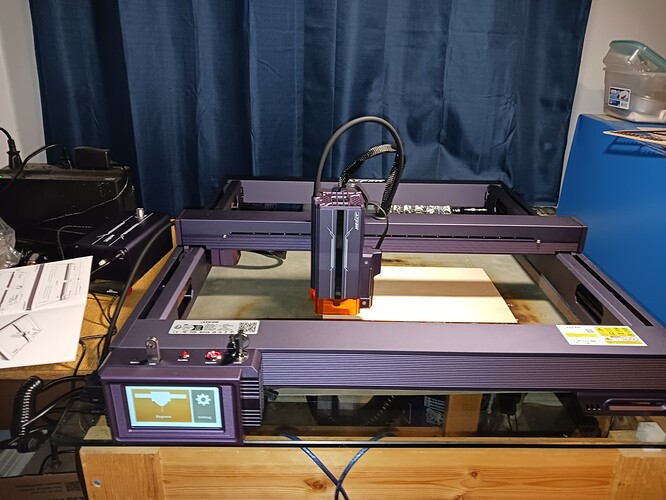

What I didn’t forsee was that Atezr was also working on a 2nd generation of their machines… the L2 series. It’s a different machine altogether… a true motorized Z-axis with auto-focus, linear bearings vs POM wheels, air-assist on/off controlled with LB, and a whole host of new features. Faster, quieter, and more powerful… I fell prey primarily to the linear-bearings and motorized Z-axis; i.e. I bought the L2 36W machine.

I’m gradually getting back into it and starting to play again with some of the inlay tests I had started with the P20. I’m very impressed with the new machine and really starting to have some fun with it.

More later.

– David

Nice to hear this. I have been looking more seriously at these lately & have come close to buying the 24W model. I was looking more at the 24W version as the 36W didn’t seem like it gave me enough advantage for the extra price. I see the 36W has a 0.08x0.1 laser spot versus 0.06x0.8mm spot for the 24W. Is that enough difference to matter? I also like the idea of getting the $160 cover with it to protect my eyes easier & route the smell & smoke to a single outlet. I used to think I wanted a CO2 laser for cutting, but one of these seems like it would work for my purposes just as well & be a lot less cumbersome. A few things I imagine using it for is cutting 1/4" cast acrylic or up to 1/2" to 3/4" plywood. Guess it would put burn marks on the edge of the acrylic. Would burning acrylic be a bad idea with the fumes? I would also eventually get their rotary axis & do away with my DIY pen engraver. I seem to recall you have the Xtool chuck rotary axis. What do you think of the Atezr rotary axis? Looks like they came out with a chuck version + the older roller style. I will add that link in case someone else wants to see this. Atezr KR PRO Multi 4-in-1 Rotary Roller for Laser Engraver

Also looks like there are some inexpensive honeycomb work panels on Amazon. Is 500mmx500mm the best size honeycomb to get for one of these? I am making myself clean up the clutter in the shed before buying one these.

Dave, now that I have it I like the additional power (36W vs 24W) and the difference in spot size is almost negligible IMO. And I’d definitely go for the Gen2 L2 machines rather than the older P-series machines… for the reasons I cited in my last post. The spot size might make a “microscopic” difference in the detail when engraving images but I doubt you could see it with the naked eye.

You definitely need an enclosure for it. The amount of material removed in the inlay photos in the last post (one pass at 2000 mm/min and 100% power) generates a lot of smoke and the Atezr enclosure does a great job of getting it out of the house. I haven’t cut any acrylic with it… only wood. You’ll still have the limitations on the colors of acrylic you can cut simply because of the wavelength of the diode laser… CO2, not so. 1/2" plywood (always “iffy” from glue inconsistencies) is probably slow but doable… and you’ll definitely appreciate having 36W over 24W. 3/4" plywood will probably drive you nuts… with either machine. If you primarily work with 1/2" material or less, you’d probably be okay with a diode laser… anything more and you’d probably be happier with CO2 or router. The small 1/4" planks of red cedar, red oak, and yellow pine that I’m resawing from limbs and construction lumber for the inlay stuff cuts like a champ with either machine.

I did get the Xtool chuck rotary, It’s very high-quality and works well… and was the only chuck rotary available at the time. It was a bit cumbersome, however, to level the work by blocking up on end with shims of some sort. For the same $$$ now, Atezr has their chuck rotary that also has the tilt adjustment to accommodate leveling the workpiece. Since I’m apparently solidly in the Atezr “ecosystem” now, I’ve already ordered one and am patiently waiting for it to magically appear on my doorstep.

I’ve got a couple of honeycomb panels, and they’re okay, but I really don’t use them all that much. I get by most of the time using some small passive heatsinks, spread around to support my workpiece where it needs support.

It’s good to hear from you, Dave.

– David

Thanks for the info & glad you are getting back to your lasers. Guess I will start leaning towards the 35W model. It is currently $341 difference, but they seem to keep offering different sales on these engravers. Maybe price will closer before long.

From their site, it shows the weight the same for 24W & 35W at 12kg. I would think the 35W was a little heavier or maybe it is less than 1kg heavier? I didn’t realize there was a problem with different color acrylics with the diode laser. After searching on this, I found this article on xTool’s site. Laser Cut Acrylic: All You Need to Know - xTool

Looks like I should be able to cut black acrylic, which is what I have. I was going to make an X-carriage for a 3d printer or two. I bought a couple of these 12"x12"x1/4" Cast Black Acrylic from openbuilds a while back. Cast Acrylic - Black - OpenBuilds Part Store

What is your workflow with Atezr? Seems like part of their software is close sourced?

I probably will get a honeycomb bed since there are some nice 3d printed hold down clamps to use with it. I know it should stay in place, but I am liable to bump it at some point.

I was early enough with both my Atezr machine purchases to get some pretty nice discounts so that ultimately I paid about the same $$$ for each of them. They’re not cheap but as I’ve said before, they are like Prusa printers… once you have one you appreciate the reliability and features they bring to the party and never regret the purchase. Plus I can hand these down to my heirs and they’ll have a better chance of figuring them out than with my “undocumented” DIY machines…

Not sure the weight comparison concern. The Atezr generation 1 and 2 machines are somewhat similar in size and construction so they’ll weigh pretty close to the same. The laser modules do get progressively larger/heavier with their power capability but in a ~12kg package you’d probably be hard-pressed to say which laser module is inside based on package weight alone.

Again, I haven’t done acrylics but only certain colors – black being one of them – cut fine with diode lasers… whereas it is my understanding that transparent/translucent “colors” won’t cut hardly, if at all. I have a CO2 laser (that I don’t like using) and it will indeed cut clear acrylic… but the diode laser won’t even mark it, regardless of the power. It’s a wavelength thing… not a power thing.

Not sure the software concerns either. There are indeed different ways to connect to these machines… wifi, usb, and touchscreen. There’s supposedly a phone app capability that’s useless to me… I hate using cellphones, except for the camera!. The touchscreen allows selecting files and running jobs from SD card… and I don’t use that either (though I do use that for my Prusa 3d-printer). You can use the USB connectivity a couple of ways… either direct Lightburn control or, as I prefer, using a Chromebook and wifi to RPi/V1Pi/CNC.js connected to USB. These machines are running Grbl 1.1h firmware and are perfectly happy with Lightburn, CNC.js, or other. I do most of my design work in Lightburn and save the gcode. Using the Chromebook’s browser, I access the V1Pi and CNC.js and then load and run the gcode file… all from my recliner.

I read somewhere about using plastic fender rivets for hold-downs on honeycomb. They’re cheap so I ordered a package of 100 and they do indeed seem they’d be useful for light hold-down tasks.

– David

Thanks for the details. I didn’t realize this machine ran grbl 1.1.h. I was thinking it had propriety firmware. Those plastic rivets do look less trouble to just go ahead & buy. My only decision now is to whether I want to spend the extra money on the 35W instead of the 24W.

Thanks again for your help.

-The other David

I’ve been really inspired by Broinwood’s magnificent cutting boards such as this one…

Hattori Hanzo cutting board #1 / butcher block. Cnc inlay. Wood inlay 4k video. - YouTube

While he’s using CNC router methods to create pockets and the contrasting inlay pieces, I wanted to see if I could reasonably mimic those operations with a laser. I can create reasonably clean and quick 2mm to 3mm deep pockets and inlays in a single pass in the red cedar, oak, and pine from abundant downed tree limbs and lumber scraps that I can easily “plank out” with my bandsaw.

Using contrasting woods – primarily red cedar and oak or pine – I start by resawing 1/4" planks from a log/limb section or scrap 2x4…

I then use my belt sander to quickly remove the saw marks from both sides of the plank…

leaving planks of ~6 mm thickness.

I then use Lightburn to create side-by-side pocket and inlay images – remembering to mirror them – and save the gcode file. I use V1Pi/CNC.js running on a RPi to connect to the laser machine, load a plank on the work bed, load the gcode into CNC.js, and then run the job. The density of cedar and pine are close enough I can use the same speed/power settings for either plank and each plank takes only 20 - 30 minutes to laser…

resulting in two pockets and two inlays… one light-on-dark and the other dark-on-light.

Glue them up and clamp overnight (longest part of the process)…

Once dry, quickly bandsaw off the backs of the glued-up inlay pieces and belt sand to reveal your masterpieces…

Your collection grows surprisingly fast…

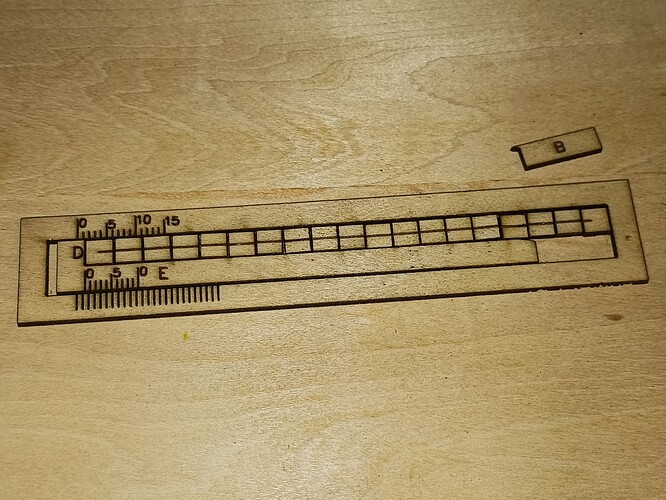

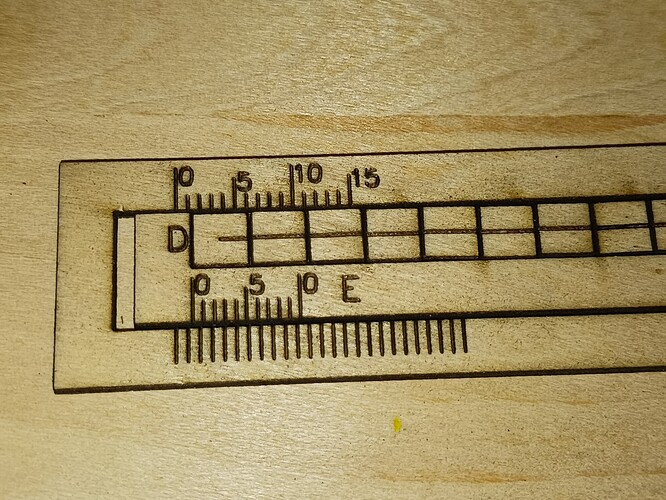

I also played a bit with the laser kerf… there’s still a tiny amount of slop before glue-up but it’s not too bad. Right now I’m using 0.07 mm – 1.4 mm / 20 cuts, shown here…

– David

Those inlays look great!

Those inlays are awesome!

Where did you get that kerf measuring ruler design?