Even if you had the skills and the plans I imagine the BOM is a few K. There is a prosumer mill that aims to be as affordable as possible but I followed a build log of it and the number Of manufacturing defects was alarming. Like rows of drilled holes visibly askew!

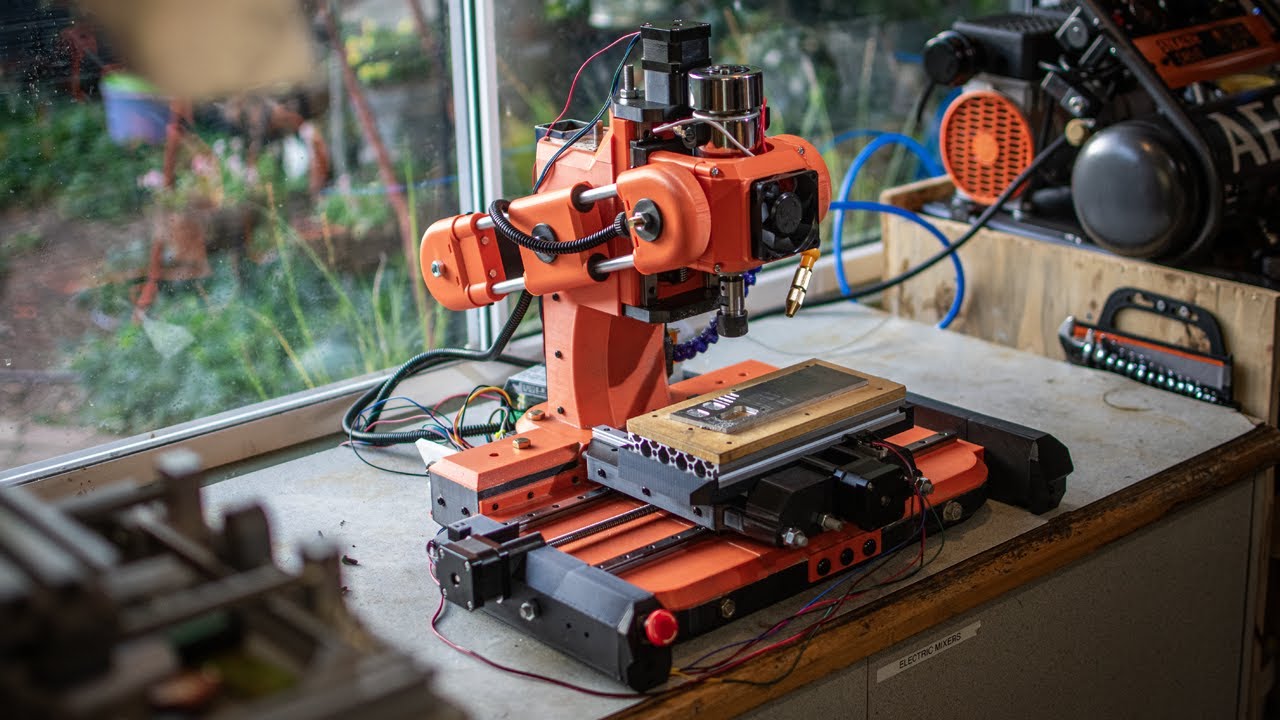

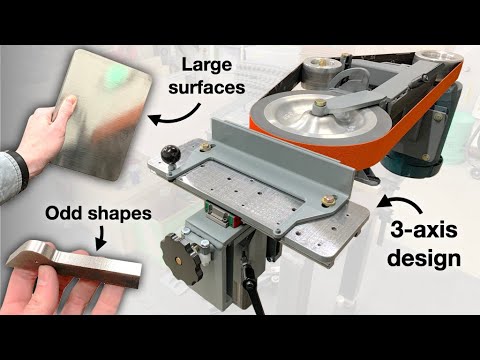

This Australian guy is doing some really cool stuff with 3d printed machines. He often 3d prints a big mold with some metal reinforcement which he fills with concrete. A cool use of a printer I’d like to experiment with.

We have other users here that have done similar with 3D printed concrete molds. It’s an interesting application for very large printed parts.

I thought that looked familiar, I watched the video he did about the lathe.

I really like this idea and things that use multiple processes, making use of the strengths of each. 3D printing things, making molds of them and then casting them in metal is another good one that I’m surprised we don’t see more of.

I’ve been meaning to print something large and hollow on my K1 max and then attempt to fill it with concrete to troll a friend of mine. A ~250mm diameter model that’s roughly spherical should be around 15kg when filled with concrete, which I think would be absolutely hilarious. Basically something that looks like it should be a few hundred grams but ends up being usable as a kettlebell…

Edit: After having watched the video, much like the lathe I think the general idea of concrete in 3D printed forms is a great idea. I think the design itself is flawed in a few ways, like the extremely weak looking anti-backlash springs and the plastic connections between the steppers and lead screws. I feel like this is likely to throw away a lot of the rigidity he’s aiming for with the concrete. Those spindles are also absolute garbage.

I’d be interested to see how far he can push it but from what he shows in the video so far I think a moderately sized LR4 would massively outperform it.

Yeah I don’t see a need to build that mill or his lathe but I like the direction he’s going.

Yea, he said in the video that the spindle is kinda crap. I believe he’s also planning on using it to make better parts for itself.

They have some really cool designs.

Came across this project. It’s a pretty neat idea. Basically he mounted a camera to his machine and has ‘paper tools’ (symbols the webcam registers position and can set up pre-defined tasks with) that he uses to set up jobs without using CAD/CAM. Personally I find the project more interesting than the application but I could imagine a workflow like this appealing to some.

I like the idea of skipping CAD/CAM and going straight to the workpiece. ![]()

Lol. So all I really need to do is transfer my Flite Test DT foamboard plans to the foam and hit “go”. ![]()

A line-follower or “paper tools” add-on to a regular CNC is kind of hacky and not a great fit except for a few specialty use-cases.

But I think line following would be perfect for the Compass Handheld CNC. You print out a giant plan for a boat or something with Matthias’ BigPrint program, tape it onto your workpiece, and then push the machine along the line and let the machine provide the accuracy.

I know it probably doesn’t fit with the current software concept, I’m just thinking what if.

Whoa, that is insane!

I dunno, I think a line follower could be pretty awesome. The Arcdroid has a workflow that’s not too dissimilar where you basically set waypoints and it cuts between them.

I could imagine a similar thing on a CNC… Draw out the shape you want, have it trace the shape with a camera, set whether you want to cut inside, outside or on the line and then have it follow that path with a pre-set behaviour in terms of speed, depth of cut, # passes, etc.

Or something like printing out a black and white image and pasting that on, having a camera scan over that and then engrave based on the results, etc.

I actually think I’d love to use something where I could just layout/draw a shape by hand and then have the CNC cut it, especially for things where I’m modifying an existing part.

Wasn’t sure if this had been posted before. Teaching Tech did an episode on it and I have been having fun doing the practice models. Learned some new stuff too!

And it’s running on FluidNC.

Man, that guy is obnoxious… I can’t stand his way of talking and cutting the videos. ![]()