Waspjr

December 23, 2024, 7:46pm

864

We get this done at work. They say it’s better than plasma spray. I absolutely hate plasma spray. I am sending some samples to see if it bonds as well as they actually say.

1 Like

Dreyfus

December 26, 2024, 9:32am

865

Came across a graphics editor embedded devices:

UI graphics editor for embedded screens with pixel perfect code builder and export. Best for Arduino, STM32, ESP32. Converts images to

uint32 and uint8 variables for Adafruit GFX, u8g2 and TFT_eSPI

It was used by the guy in this video who looks like he made his own M5Dial from scratch, which is interesting too.

I was going to post it in the WebUI thread but it’s not fair to make Jason Squirrel with another distraction

7 Likes

Dreyfus

December 26, 2024, 10:01pm

866

Another esp32 with a screen and rotary encoder.

Note [For orange button]: Since the edge of the button is orange, the color of the light shown in RGB is recommended to use white light, if the corresponding RGB color cannot be displayed, please purchase carefully. T-Embed is an IoT...

Price: USD 1.96

1 Like

Dreyfus

December 31, 2024, 11:19am

867

Someone’s trying to develop full colour 3d printing at home. Cool.

4 Likes

Bigchepin

January 6, 2025, 10:13pm

870

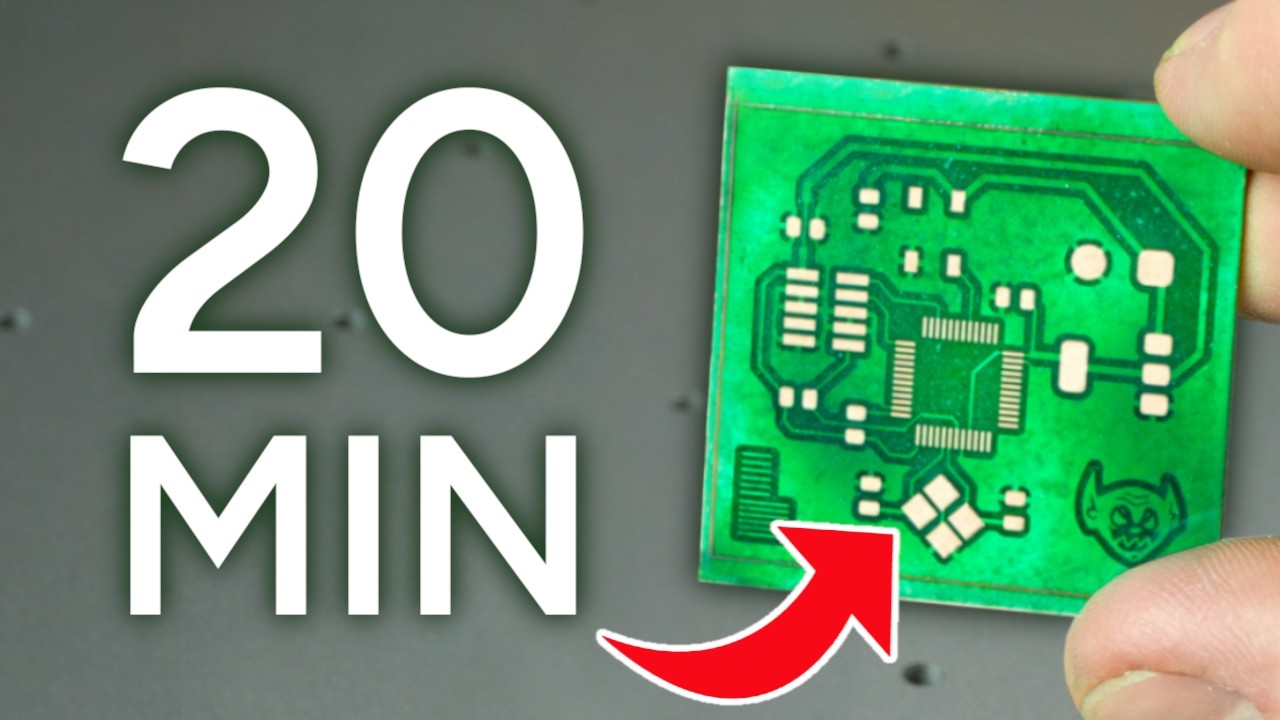

This is pretty slick if you have a fiber laser and can’t wait for board house.

3 Likes

Dreyfus

January 7, 2025, 12:12pm

872

‘They gave me this 2k laser cutter for free, but this video isn’t sponsored’

4 Likes

He didn’t have to make the video.

Devhammer

January 7, 2025, 6:15pm

874

Build a Gothic-style Monastery with CNC, without any CNC experience? These monks are doing just that:

The sheer scale in terms of the size and weight of the stone being used is mind-boggling.

And as a fan of Gothic architecture, this is especially cool to me. Here’s one of the machines they’re using:

A wee bit beyond my humble Primo…

5 Likes

22k subscribers… yeah, they did! I have no issues with manufacturer’s giving content creators stuff, and if it’s free they should say so. I do have issues when the content creators then offer affiliate links (these guys don’t so they get a pass from me) or when they do half baked “reviews”.

I was thinking about the “good old days” when reviewers would have stuff for months before magazines were published, the reviews then weren’t always objective either, but at least there was proper testing done. These days the race to be first wins the views, so nothing is objective.

jeyeager

January 10, 2025, 2:47pm

876

This is a cool 4 axis camera motion control rig running FluidNC! One of those axes is camera zoom.

Found out about it in this FluidNC github issue:

opened 09:13AM - 06 Nov 24 UTC

### Wiki Search Terms

G93, feedrate, inverse

### Controller Board

ESP32… WROOM-32

### Machine Description

Two naked boards without any periphery connected except two probes to my oscilloscope to measure the timing.

One machine is configured with 4 axis and the other one is configured with 1 axis (plus two dummy ones).

Both machines have user output pins defined. I toggle these pins at the start and end of the program to measure timing with my oscilloscope.

I have pasted both my config files in the config file section

### Input Circuits

```yaml

Two naked boards without any periphery connected except two probes to my oscilloscope to measure the timing.

```

### Configuration file

```yaml

#########################################

# first config file

board: ESPDUINO-32

name: PANTS

user_outputs:

digital0_pin: gpio.2

digital1_pin: gpio.4

axes:

shared_stepper_disable_pin: gpio.12:high

x:

steps_per_mm: 160

max_rate_mm_per_min: 10000

acceleration_mm_per_sec2: 500

max_travel_mm: 1000

motor0:

stepstick:

direction_pin: gpio.16:low

step_pin: gpio.26

y:

steps_per_mm: 257.777

max_rate_mm_per_min: 10000

acceleration_mm_per_sec2: 500

max_travel_mm: 1000

motor0:

stepstick:

direction_pin: gpio.27

step_pin: gpio.25

z:

steps_per_mm: 257.777

max_rate_mm_per_min: 10000

acceleration_mm_per_sec2: 500

max_travel_mm: 1000

motor0:

stepstick:

direction_pin: gpio.14:low

step_pin: gpio.17

a:

steps_per_mm: 44.444

max_rate_mm_per_min: 40000

acceleration_mm_per_sec2: 3000

motor0:

stepstick:

direction_pin: gpio.18

step_pin: gpio.19

##############################

# second config file

board: Wemos D1 mini

name: Rotodactyl

user_outputs:

digital0_pin: gpio.2

digital1_pin: gpio.4

axes:

shared_stepper_disable_pin: gpio.27:high

x:

steps_per_mm: 113.333

max_rate_mm_per_min: 16900

acceleration_mm_per_sec2: 500

motor0:

limit_all_pin: NO_PIN

stepstick:

direction_pin: gpio.32

step_pin: gpio.25

```

### Startup Messages

```text

#########################

# First startup message #

#########################

ets Jul 29 2019 12:21:46

rst:0x1 (POWERON_RESET),boot:0x13 (SPI_FAST_FLASH_BOOT)

configsip: 0, SPIWP:0xee

clk_drv:0x00,q_drv:0x00,d_drv:0x00,cs0_drv:0x00,hd_drv:0x00,wp_drv:0x00

mode:DIO, clock div:1

load:0x3fff0030,len:1184

load:0x40078000,len:13260

load:0x40080400,len:3028

entry 0x400805e4

[MSG:INFO: uart_channel0 created]

[MSG:RST]

[MSG:INFO: FluidNC v3.9.1 https://github.com/bdring/FluidNC]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.7-dirty]

[MSG:INFO: Local filesystem type is spiffs]

[MSG:INFO: Configuration file:config.yaml]

[MSG:INFO: Machine PANTS]

[MSG:INFO: Board ESPDUINO-32]

[MSG:INFO: Stepping:RMT Pulse:4us Dsbl Delay:0us Dir Delay:0us Idle Delay:255ms]

[MSG:INFO: User Digital Output: 0 on Pin:gpio.2]

[MSG:INFO: User Digital Output: 1 on Pin:gpio.4]

[MSG:INFO: Axis count 4]

[MSG:INFO: Shared stepper disable gpio.12]

[MSG:INFO: Axis X (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: stepstick Step:gpio.26 Dir:gpio.16:low Disable:NO_PIN]

[MSG:INFO: Axis Y (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: stepstick Step:gpio.25 Dir:gpio.27 Disable:NO_PIN]

[MSG:INFO: Axis Z (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: stepstick Step:gpio.17 Dir:gpio.14:low Disable:NO_PIN]

[MSG:INFO: Axis A (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: stepstick Step:gpio.19 Dir:gpio.18 Disable:NO_PIN]

[MSG:INFO: Kinematic system: Cartesian]

[MSG:INFO: STA SSID is not set]

[MSG:INFO: AP SSID FluidNC IP 192.168.0.1 mask 255.255.255.0 channel 1]

[MSG:INFO: AP started]

[MSG:INFO: WiFi on]

[MSG:INFO: Captive Portal Started]

[MSG:INFO: HTTP started on port 80]

[MSG:INFO: Telnet started on port 23]

Grbl 3.9 [FluidNC v3.9.1 (wifi) '$' for help]

##########################

# second startup message #

##########################

ets Jul 29 2019 12:21:46

rst:0x1 (POWERON_RESET),boot:0x13 (SPI_FAST_FLASH_BOOT)

configsip: 0, SPIWP:0xee

clk_drv:0x00,q_drv:0x00,d_drv:0x00,cs0_drv:0x00,hd_drv:0x00,wp_drv:0x00

mode:DIO, clock div:1

load:0x3fff0030,len:1184

load:0x40078000,len:13260

load:0x40080400,len:3028

entry 0x400805e4

[MSG:INFO: uart_channel0 created]

[MSG:RST]

[MSG:INFO: FluidNC v3.9.1 https://github.com/bdring/FluidNC]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.7-dirty]

[MSG:INFO: Local filesystem type is spiffs]

[MSG:INFO: Configuration file:config.yaml]

[MSG:INFO: Machine Rotodactyl]

[MSG:INFO: Board Wemos D1 mini]

[MSG:INFO: Stepping:RMT Pulse:4us Dsbl Delay:0us Dir Delay:0us Idle Delay:255ms]

[MSG:INFO: User Digital Output: 0 on Pin:gpio.2]

[MSG:INFO: User Digital Output: 1 on Pin:gpio.4]

[MSG:INFO: Axis count 3]

[MSG:INFO: Shared stepper disable gpio.27]

[MSG:INFO: Axis X (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: stepstick Step:gpio.25 Dir:gpio.32 Disable:NO_PIN]

[MSG:INFO: Axis Y (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: Axis Z (-1000.000,0.000)]

[MSG:INFO: Motor0]

[MSG:INFO: Kinematic system: Cartesian]

[MSG:INFO: STA SSID is not set]

[MSG:INFO: AP SSID FluidNC IP 192.168.0.1 mask 255.255.255.0 channel 1]

[MSG:INFO: AP started]

[MSG:INFO: WiFi on]

[MSG:INFO: Captive Portal Started]

[MSG:INFO: HTTP started on port 80]

[MSG:INFO: Telnet started on port 23]

Grbl 3.9 [FluidNC v3.9.1 (wifi) '$' for help]

```

### User Interface Software

FluidTerm, custom python program

### What happened?

I create two gcode files with the same amount of moves. All moves are G93 inverse feedrate moves and have the same duration.

The only difference is that one file has four axes and the other has only one. At the begin and ending of both programs I toggle a user output pin to measure timing between the two controllers with my oscilloscope. I upload the files to the controllers via xmodem and start them with $LocalFS/Run=moco.nc . I send the start command to both controllers via custom python code. The first pulse that indicates the start of the program has a deviation of about 2ms between controller 1 and controller 2. The second pulse has as a deviation of 1.3 seconds between controllers. The whole program runs for 7.1 seconds on controller two, executing 200 moves. Each move should take 41.7ms (1/24 s). All moves should therefore take 8.33s .

Controller one finishes correctly in 8.3s.

### GCode File

# first gcode file

G94

G0X0.00Z89.00Y-90.00A100.00

G93

M62 P1

G4 P0.1

M63 P1

G1X0.00Z89.00Y-90.00A100.00F1440.00

G1X0.00Z89.00Y-90.00A100.00F1440.00

G1X0.35Z89.00Y-90.00A100.00F1440.00

G1X0.70Z89.00Y-90.00A100.00F1440.00

G1X1.06Z89.00Y-90.00A100.00F1440.00

G1X1.43Z89.00Y-90.00A100.01F1440.00

G1X1.81Z89.00Y-90.00A100.01F1440.00

G1X2.19Z89.00Y-90.00A100.02F1440.00

G1X2.57Z89.00Y-90.00A100.02F1440.00

G1X2.97Z89.00Y-90.00A100.03F1440.00

G1X3.37Z89.00Y-90.00A100.04F1440.00

G1X3.77Z89.00Y-90.00A100.05F1440.00

G1X4.18Z88.99Y-90.00A100.06F1440.00

G1X4.60Z88.99Y-90.00A100.07F1440.00

G1X5.02Z88.99Y-90.00A100.08F1440.00

G1X5.45Z88.99Y-90.00A100.09F1440.00

G1X5.88Z88.99Y-90.00A100.11F1440.00

G1X6.32Z88.99Y-90.00A100.12F1440.00

G1X6.76Z88.99Y-90.00A100.14F1440.00

G1X7.21Z88.99Y-90.00A100.15F1440.00

G1X7.66Z88.99Y-90.00A100.17F1440.00

G1X8.12Z88.99Y-90.00A100.19F1440.00

G1X8.58Z88.99Y-90.00A100.21F1440.00

G1X9.04Z88.99Y-90.00A100.23F1440.00

G1X9.52Z88.99Y-90.00A100.25F1440.00

G1X9.99Z88.99Y-90.00A100.27F1440.00

G1X10.47Z88.99Y-90.00A100.29F1440.00

G1X10.96Z88.99Y-90.00A100.31F1440.00

G1X11.44Z88.99Y-90.00A100.34F1440.00

G1X11.94Z88.99Y-90.00A100.36F1440.00

G1X12.43Z88.99Y-90.00A100.39F1440.00

G1X12.93Z88.99Y-90.00A100.42F1440.00

G1X13.44Z88.99Y-90.00A100.44F1440.00

G1X13.95Z88.99Y-90.00A100.47F1440.00

G1X14.46Z88.98Y-90.00A100.50F1440.00

G1X14.97Z88.98Y-90.00A100.53F1440.00

G1X15.49Z88.98Y-90.00A100.56F1440.00

G1X16.02Z88.98Y-90.00A100.60F1440.00

G1X16.54Z88.98Y-90.00A100.63F1440.00

G1X17.07Z88.98Y-90.00A100.66F1440.00

G1X17.61Z88.98Y-90.00A100.70F1440.00

G1X18.14Z88.98Y-90.00A100.73F1440.00

G1X18.68Z88.98Y-90.00A100.77F1440.00

G1X19.23Z88.98Y-90.00A100.81F1440.00

G1X19.77Z88.98Y-90.00A100.84F1440.00

G1X20.32Z88.98Y-90.00A100.88F1440.00

G1X20.88Z88.98Y-90.00A100.92F1440.00

G1X21.43Z88.98Y-90.00A100.96F1440.00

G1X21.99Z88.98Y-90.00A101.00F1440.00

G1X22.55Z88.98Y-90.00A101.05F1440.00

G1X23.12Z88.98Y-90.00A101.09F1440.00

G1X23.69Z88.97Y-90.00A101.13F1440.00

G1X24.26Z88.97Y-90.00A101.18F1440.00

G1X24.83Z88.97Y-90.00A101.22F1440.00

G1X25.41Z88.97Y-90.00A101.27F1440.00

G1X25.99Z88.97Y-90.00A101.32F1440.00

G1X26.57Z88.97Y-90.00A101.36F1440.00

G1X27.15Z88.97Y-90.00A101.41F1440.00

G1X27.74Z88.97Y-90.00A101.46F1440.00

G1X28.33Z88.97Y-90.00A101.51F1440.00

G1X28.92Z88.97Y-90.00A101.56F1440.00

G1X29.52Z88.97Y-90.00A101.61F1440.00

G1X30.12Z88.97Y-90.00A101.66F1440.00

G1X30.72Z88.97Y-90.00A101.72F1440.00

G1X31.32Z88.97Y-90.00A101.77F1440.00

G1X31.92Z88.97Y-90.00A101.83F1440.00

G1X32.53Z88.97Y-90.00A101.88F1440.00

G1X33.14Z88.96Y-90.00A101.94F1440.00

G1X33.75Z88.96Y-90.00A101.99F1440.00

G1X34.36Z88.96Y-90.00A102.05F1440.00

G1X34.98Z88.96Y-90.00A102.11F1440.00

G1X35.60Z88.96Y-90.00A102.17F1440.00

G1X36.22Z88.96Y-90.00A102.23F1440.00

G1X36.84Z88.96Y-90.00A102.29F1440.00

G1X37.47Z88.96Y-90.00A102.35F1440.00

G1X38.10Z88.96Y-90.00A102.41F1440.00

G1X38.73Z88.96Y-90.00A102.47F1440.00

G1X39.36Z88.96Y-90.00A102.54F1440.00

G1X39.99Z88.96Y-90.00A102.60F1440.00

G1X40.63Z88.96Y-90.00A102.67F1440.00

G1X41.26Z88.96Y-90.00A102.73F1440.00

G1X41.90Z88.96Y-90.00A102.80F1440.00

G1X42.54Z88.95Y-90.00A102.87F1440.00

G1X43.19Z88.95Y-90.00A102.93F1440.00

G1X43.83Z88.95Y-90.00A103.00F1440.00

G1X44.48Z88.95Y-90.00A103.07F1440.00

G1X45.13Z88.95Y-90.00A103.14F1440.00

G1X45.78Z88.95Y-90.00A103.21F1440.00

G1X46.43Z88.95Y-90.00A103.28F1440.00

G1X47.09Z88.95Y-90.00A103.35F1440.00

G1X47.74Z88.95Y-90.00A103.43F1440.00

G1X48.40Z88.95Y-90.00A103.50F1440.00

G1X49.06Z88.95Y-90.00A103.57F1440.00

G1X49.72Z88.95Y-90.00A103.65F1440.00

G1X50.38Z88.95Y-90.00A103.72F1440.00

G1X51.05Z88.95Y-90.00A103.80F1440.00

G1X51.72Z88.94Y-90.00A103.88F1440.00

G1X52.38Z88.94Y-90.00A103.95F1440.00

G1X53.05Z88.94Y-90.00A104.03F1440.00

G1X53.72Z88.94Y-90.00A104.11F1440.00

G1X54.40Z88.94Y-90.00A104.19F1440.00

G1X55.07Z88.94Y-90.00A104.27F1440.00

G1X55.75Z88.94Y-90.00A104.35F1440.00

G1X56.43Z88.94Y-90.00A104.43F1440.00

G1X57.10Z88.94Y-90.00A104.51F1440.00

G1X57.79Z88.94Y-90.00A104.59F1440.00

G1X58.47Z88.94Y-90.00A104.68F1440.00

G1X59.15Z88.94Y-90.00A104.76F1440.00

G1X59.84Z88.94Y-90.00A104.85F1440.00

G1X60.52Z88.93Y-90.00A104.93F1440.00

G1X61.21Z88.93Y-90.00A105.02F1440.00

G1X61.90Z88.93Y-90.00A105.10F1440.00

G1X62.59Z88.93Y-90.00A105.19F1440.00

G1X63.28Z88.93Y-90.00A105.28F1440.00

G1X63.98Z88.93Y-90.00A105.36F1440.00

G1X64.67Z88.93Y-90.00A105.45F1440.00

G1X65.37Z88.93Y-90.00A105.54F1440.00

G1X66.06Z88.93Y-90.00A105.63F1440.00

G1X66.76Z88.93Y-90.00A105.72F1440.00

G1X67.46Z88.93Y-90.00A105.81F1440.00

G1X68.16Z88.93Y-90.00A105.90F1440.00

G1X68.87Z88.93Y-90.00A106.00F1440.00

G1X69.57Z88.92Y-90.00A106.09F1440.00

G1X70.28Z88.92Y-90.00A106.18F1440.00

G1X70.98Z88.92Y-90.00A106.28F1440.00

G1X71.69Z88.92Y-90.00A106.37F1440.00

G1X72.40Z88.92Y-90.00A106.47F1440.00

G1X73.11Z88.92Y-90.00A106.56F1440.00

G1X73.82Z88.92Y-90.00A106.66F1440.00

G1X74.53Z88.92Y-90.00A106.75F1440.00

G1X75.25Z88.92Y-90.00A106.85F1440.00

G1X75.96Z88.92Y-90.00A106.95F1440.00

G1X76.68Z88.92Y-90.00A107.05F1440.00

G1X77.39Z88.92Y-90.00A107.15F1440.00

G1X78.11Z88.91Y-90.00A107.25F1440.00

G1X78.83Z88.91Y-90.00A107.35F1440.00

G1X79.55Z88.91Y-90.00A107.45F1440.00

G1X80.27Z88.91Y-90.00A107.55F1440.00

G1X81.00Z88.91Y-90.00A107.65F1440.00

G1X81.72Z88.91Y-90.00A107.75F1440.00

G1X82.45Z88.91Y-90.00A107.85F1440.00

G1X83.17Z88.91Y-90.00A107.96F1440.00

G1X83.90Z88.91Y-90.00A108.06F1440.00

G1X84.63Z88.91Y-90.00A108.16F1440.00

G1X85.36Z88.91Y-90.00A108.27F1440.00

G1X86.09Z88.90Y-90.00A108.37F1440.00

G1X86.82Z88.90Y-90.00A108.48F1440.00

G1X87.55Z88.90Y-90.00A108.59F1440.00

G1X88.28Z88.90Y-90.00A108.69F1440.00

G1X89.02Z88.90Y-90.00A108.80F1440.00

G1X89.75Z88.90Y-90.00A108.91F1440.00

G1X90.49Z88.90Y-90.00A109.02F1440.00

G1X91.22Z88.90Y-90.00A109.12F1440.00

G1X91.96Z88.90Y-90.00A109.23F1440.00

G1X92.70Z88.90Y-90.00A109.34F1440.00

G1X93.44Z88.90Y-90.00A109.45F1440.00

G1X94.18Z88.90Y-90.00A109.56F1440.00

G1X94.92Z88.89Y-90.00A109.67F1440.00

G1X95.66Z88.89Y-90.00A109.79F1440.00

G1X96.41Z88.89Y-90.00A109.90F1440.00

G1X97.15Z88.89Y-90.00A110.01F1440.00

G1X97.90Z88.89Y-90.00A110.12F1440.00

G1X98.64Z88.89Y-90.00A110.24F1440.00

G1X99.39Z88.89Y-90.00A110.35F1440.00

G1X100.14Z88.89Y-90.00A110.46F1440.00

G1X100.88Z88.89Y-90.00A110.58F1440.00

G1X101.63Z88.89Y-90.00A110.69F1440.00

G1X102.38Z88.89Y-90.00A110.81F1440.00

G1X103.14Z88.88Y-90.00A110.93F1440.00

G1X103.89Z88.88Y-90.00A111.04F1440.00

G1X104.64Z88.88Y-90.00A111.16F1440.00

G1X105.39Z88.88Y-90.00A111.28F1440.00

G1X106.15Z88.88Y-90.00A111.39F1440.00

G1X106.90Z88.88Y-90.00A111.51F1440.00

G1X107.66Z88.88Y-90.00A111.63F1440.00

G1X108.41Z88.88Y-90.00A111.75F1440.00

G1X109.17Z88.88Y-90.00A111.87F1440.00

G1X109.93Z88.88Y-90.00A111.99F1440.00

G1X110.69Z88.87Y-90.00A112.11F1440.00

G1X111.45Z88.87Y-90.00A112.23F1440.00

G1X112.21Z88.87Y-90.00A112.35F1440.00

G1X112.97Z88.87Y-90.00A112.47F1440.00

G1X113.73Z88.87Y-90.00A112.59F1440.00

G1X114.49Z88.87Y-90.00A112.72F1440.00

G1X115.26Z88.87Y-90.00A112.84F1440.00

G1X116.02Z88.87Y-90.00A112.96F1440.00

G1X116.79Z88.87Y-90.00A113.09F1440.00

G1X117.55Z88.87Y-90.00A113.21F1440.00

G1X118.32Z88.86Y-90.00A113.33F1440.00

G1X119.08Z88.86Y-90.00A113.46F1440.00

G1X119.85Z88.86Y-90.00A113.58F1440.00

G1X120.62Z88.86Y-90.00A113.71F1440.00

G1X121.39Z88.86Y-90.00A113.83F1440.00

G1X122.16Z88.86Y-90.00A113.96F1440.00

G1X122.93Z88.86Y-90.00A114.09F1440.00

G1X123.70Z88.86Y-90.00A114.21F1440.00

G1X124.47Z88.86Y-90.00A114.34F1440.00

G1X125.24Z88.86Y-90.00A114.47F1440.00

G1X126.02Z88.85Y-90.00A114.59F1440.00

G1X126.79Z88.85Y-90.00A114.72F1440.00

M62 P1

G4 P0.1

M63 P1

# second gcode file

G94

G0X104.80

G93

M62 P1

G4 P0.1

M63 P1

G1X104.80F1440.00

G1X104.80F1440.00

G1X104.81F1440.00

G1X104.82F1440.00

G1X104.83F1440.00

G1X104.83F1440.00

G1X104.84F1440.00

G1X104.85F1440.00

G1X104.86F1440.00

G1X104.86F1440.00

G1X104.87F1440.00

G1X104.88F1440.00

G1X104.89F1440.00

G1X104.90F1440.00

G1X104.91F1440.00

G1X104.91F1440.00

G1X104.92F1440.00

G1X104.93F1440.00

G1X104.94F1440.00

G1X104.95F1440.00

G1X104.96F1440.00

G1X104.97F1440.00

G1X104.98F1440.00

G1X104.99F1440.00

G1X105.00F1440.00

G1X105.01F1440.00

G1X105.02F1440.00

G1X105.03F1440.00

G1X105.04F1440.00

G1X105.05F1440.00

G1X105.06F1440.00

G1X105.07F1440.00

G1X105.08F1440.00

G1X105.09F1440.00

G1X105.10F1440.00

G1X105.11F1440.00

G1X105.12F1440.00

G1X105.13F1440.00

G1X105.15F1440.00

G1X105.16F1440.00

G1X105.17F1440.00

G1X105.18F1440.00

G1X105.19F1440.00

G1X105.20F1440.00

G1X105.21F1440.00

G1X105.23F1440.00

G1X105.24F1440.00

G1X105.25F1440.00

G1X105.26F1440.00

G1X105.27F1440.00

G1X105.29F1440.00

G1X105.30F1440.00

G1X105.31F1440.00

G1X105.32F1440.00

G1X105.34F1440.00

G1X105.35F1440.00

G1X105.36F1440.00

G1X105.37F1440.00

G1X105.39F1440.00

G1X105.40F1440.00

G1X105.41F1440.00

G1X105.43F1440.00

G1X105.44F1440.00

G1X105.45F1440.00

G1X105.46F1440.00

G1X105.48F1440.00

G1X105.49F1440.00

G1X105.51F1440.00

G1X105.52F1440.00

G1X105.53F1440.00

G1X105.55F1440.00

G1X105.56F1440.00

G1X105.57F1440.00

G1X105.59F1440.00

G1X105.60F1440.00

G1X105.62F1440.00

G1X105.63F1440.00

G1X105.64F1440.00

G1X105.66F1440.00

G1X105.67F1440.00

G1X105.69F1440.00

G1X105.70F1440.00

G1X105.72F1440.00

G1X105.73F1440.00

G1X105.75F1440.00

G1X105.76F1440.00

G1X105.77F1440.00

G1X105.79F1440.00

G1X105.80F1440.00

G1X105.82F1440.00

G1X105.83F1440.00

G1X105.85F1440.00

G1X105.87F1440.00

G1X105.88F1440.00

G1X105.90F1440.00

G1X105.91F1440.00

G1X105.93F1440.00

G1X105.94F1440.00

G1X105.96F1440.00

G1X105.97F1440.00

G1X105.99F1440.00

G1X106.01F1440.00

G1X106.02F1440.00

G1X106.04F1440.00

G1X106.05F1440.00

G1X106.07F1440.00

G1X106.09F1440.00

G1X106.10F1440.00

G1X106.12F1440.00

G1X106.14F1440.00

G1X106.15F1440.00

G1X106.17F1440.00

G1X106.18F1440.00

G1X106.20F1440.00

G1X106.22F1440.00

G1X106.23F1440.00

G1X106.25F1440.00

G1X106.27F1440.00

G1X106.29F1440.00

G1X106.30F1440.00

G1X106.32F1440.00

G1X106.34F1440.00

G1X106.35F1440.00

G1X106.37F1440.00

G1X106.39F1440.00

G1X106.41F1440.00

G1X106.42F1440.00

G1X106.44F1440.00

G1X106.46F1440.00

G1X106.48F1440.00

G1X106.49F1440.00

G1X106.51F1440.00

G1X106.53F1440.00

G1X106.55F1440.00

G1X106.57F1440.00

G1X106.58F1440.00

G1X106.60F1440.00

G1X106.62F1440.00

G1X106.64F1440.00

G1X106.66F1440.00

G1X106.68F1440.00

G1X106.70F1440.00

G1X106.71F1440.00

G1X106.73F1440.00

G1X106.75F1440.00

G1X106.77F1440.00

G1X106.79F1440.00

G1X106.81F1440.00

G1X106.83F1440.00

G1X106.85F1440.00

G1X106.86F1440.00

G1X106.88F1440.00

G1X106.90F1440.00

G1X106.92F1440.00

G1X106.94F1440.00

G1X106.96F1440.00

G1X106.98F1440.00

G1X107.00F1440.00

G1X107.02F1440.00

G1X107.04F1440.00

G1X107.06F1440.00

G1X107.08F1440.00

G1X107.10F1440.00

G1X107.12F1440.00

G1X107.14F1440.00

G1X107.16F1440.00

G1X107.18F1440.00

G1X107.20F1440.00

G1X107.22F1440.00

G1X107.24F1440.00

G1X107.26F1440.00

G1X107.28F1440.00

G1X107.30F1440.00

G1X107.32F1440.00

G1X107.34F1440.00

G1X107.37F1440.00

G1X107.39F1440.00

G1X107.41F1440.00

G1X107.43F1440.00

G1X107.45F1440.00

G1X107.47F1440.00

G1X107.49F1440.00

G1X107.51F1440.00

G1X107.53F1440.00

G1X107.56F1440.00

G1X107.58F1440.00

G1X107.60F1440.00

G1X107.62F1440.00

G1X107.64F1440.00

G1X107.66F1440.00

G1X107.69F1440.00

G1X107.71F1440.00

G1X107.73F1440.00

G1X107.75F1440.00

G1X107.78F1440.00

G1X107.80F1440.00

G1X107.82F1440.00

G1X107.84F1440.00

G1X107.86F1440.00

G1X107.89F1440.00

M62 P1

G4 P0.1

M63 P1

### Other Information

I have tested this with version 3.8.4-pre5 and 3.9.1

If both controllers have the same file, they start and finish at the same time.

The overall delay varies with the number of moves.

7 Likes

Every now and then something bobs up that gives me a head slapping moment! Why hadn’t I thought of modelling hole shapes as negative inserts before?

2 Likes

vicious1

January 10, 2025, 11:03pm

878

I have not watched one of his videos in a long time, I like the tip about modeling the entire screw. That might come in handy with all the overhang counter sink pockets I use that normally take 3+ operations. I will have to give it a shot and see if it is any faster for me.

I occasionally take a peek, but let’s say despite the occasional gem (like this one) we have divergent personalities and leave it at that!

I don’t see how it can’t be! You just keep one single model on file and use it “derived” repeatedly - Even magnet and bolt inserts or even the old “cantilevered countersink” trick now that I think about it ;- just add a “point” and create the mate connector. BAM!!

I might even just use Tom’s models as a sort of payback!

3 Likes

Devhammer

January 11, 2025, 2:43am

880

I wasn’t sure about this video at the start, since it seemed like it was just a rehash of stuff he’d covered before, but I agree that the tips around modeling were very helpful!

1 Like

It’s a measure of the hypocrisy of youtube presenters generally that Tom’s just quietly using Onshape again. Yes I know it was six years ago, but he made a big song and dance about the change in terms for the free version, and he hasn’t removed the video.

Back then he said;

"and it drastically changes what you can do with it on the free plan.

Autodesk must have taken away his affiliate links.

4 Likes

dos

January 11, 2025, 4:36am

882

I like to keep negative space objects (on their own layer) grouped with my fastener objects. Everytime I add a fastener somewhere I then not only have the clearances for the fastener confirmed but I also have the cutouts accurately positioned… and include small details like chamfers on the hole that I’ll often be too lazy (uh, time pressed) to include if I’m doing each hole manually.

I also like to use drywall screws to reinforce pieces that might otherwise snap off between layers. Using the drywall screw model (not from McMaster Carr, of course

10 Likes

Dreyfus

January 11, 2025, 8:48pm

883

Some interesting design ideas. Granite epoxy for mass and rigidity (fancy concrete) and I notice he’s using a fluid dial

Note the built in round display - separate from the pendant

3 Likes

Waspjr

January 13, 2025, 5:04pm

884

Iirc the granite epoxy helps with resonance as well.

![]()

![]()

![]()

![]()

![]()

![]() ) as the negative model for these holes works great.

) as the negative model for these holes works great.