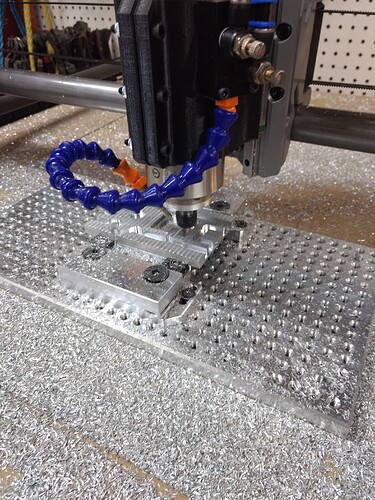

Starting to get the settings real dialed in for aluminum! Little bit of mist coolant didnt hurt either!

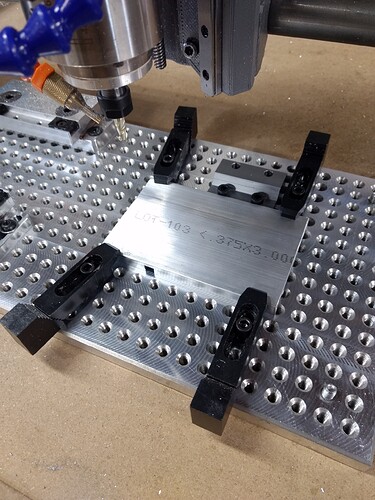

Finished up some tweaks so 25mm and 32mm tubing will work with the new metric parts!

https://www.printables.com/model/190417-printed-cnc-brutus-metric-tubing

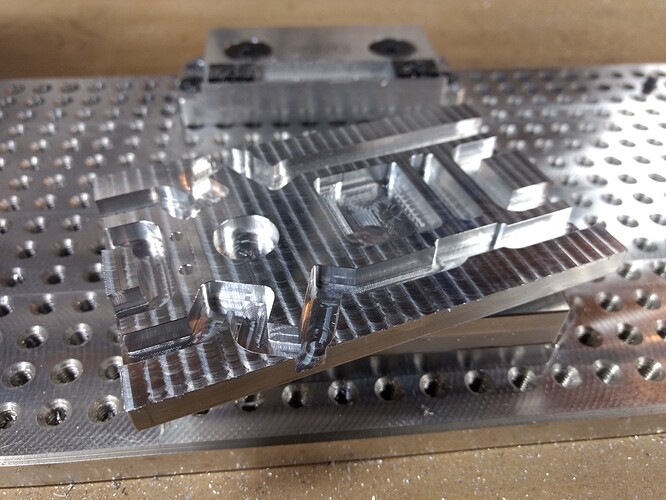

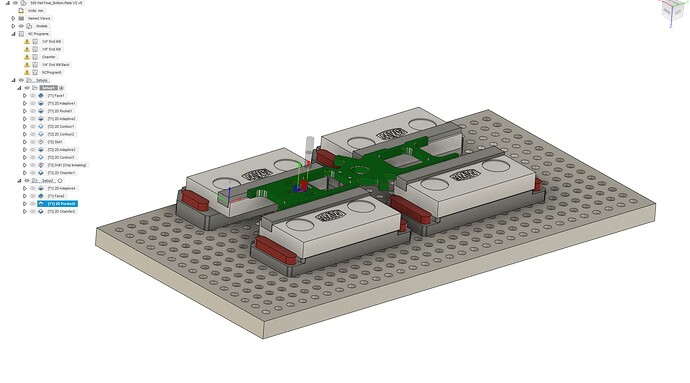

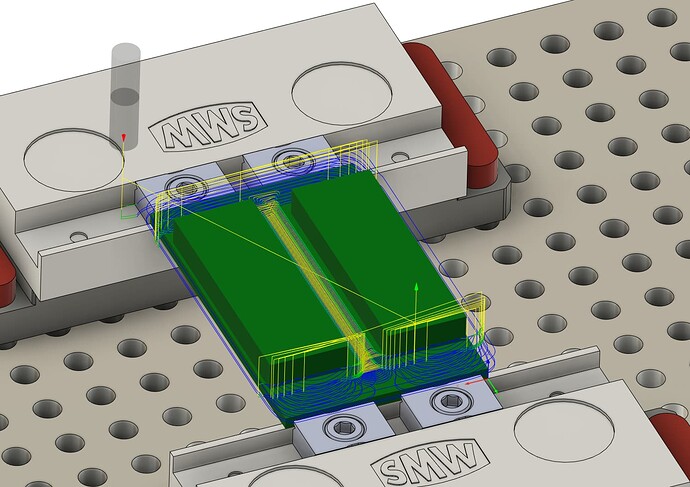

Did some more tool path testing today, even got to test the second setup! Other than a resonance that starts during slotting between the spindle and bed, got it cutting pretty good I think! Really got to build a nicer table for this thing.

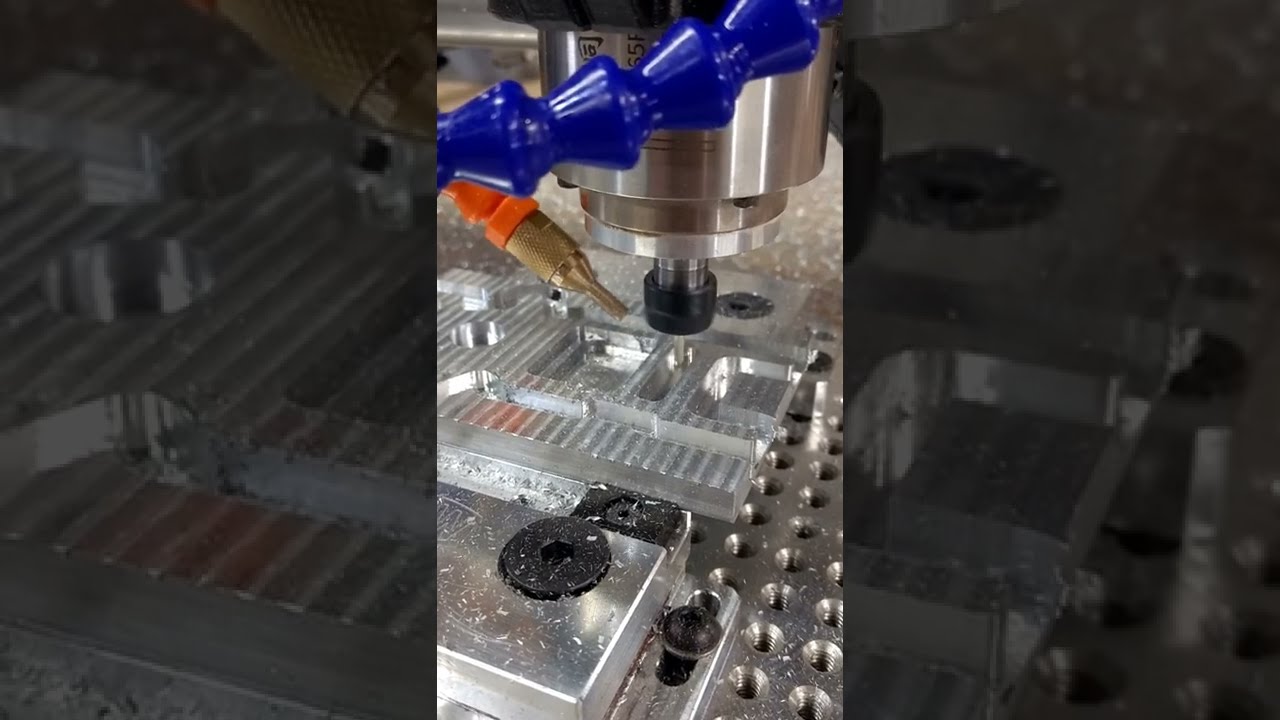

Did however take a couple snippets of some tool paths!

Nice! If you’re using fusion, you can change the lead in/out speeds to really save some time on adaptive paths.

Looks really solid, very very good work.

I’ll keep that in mind! Still working on finding the goldilocks doc and step over. 3mm doc and 3mm step over @ 42ipm works but makes a bit of noise beyond just cutting at times, 2mm doc and 3mm step over is ok and I use that on the internal stuff, just want to use some more flute if I can.

The chamfer looks worse than it actually is, but I still could use a little more tuning on it.

Imo using more flute is something of a siren song. Sounds beautiful and makes you dream of a perfect world, drawing you in with empty promises.

In aluminum, you’ll probably crash the tool or drop it before you wear it out (assuming good carbide, not HSS). So the only real benefit might be higher MRR from going deeper. But then, mrr only matters of you spend enough time cutting and not rapiding/travelling. For modt of us, you have to bring the stepover down so far that you run into the machine’s speed limit trying to make it back up.

I get the best results at moderate DOC, fat stepover, full send(1/8 mill)

You might have a lot more rigidity than most of us, too, though. It does look really solid, so I’ll cross my fingers for you.

I gave up on cheap cutters early on in my hobby machining career lol. Been using the Shars Zrn coated carbides on the CNC as a cheaper learning bit. Did order one of my favorite end mills in a 2 flute variety to try though (Gorilla Mill Silverback, they have a variable helix, crushes any chatter I used to get on the manual mill and leaves a beautiful finish).

It is more of a can I do it for the doc, not so much a need lol. Do want to try a 3 flute at 70 ipm though just to see what happens, chip load and hp requirements are met for it (3mm doc 1.5mm step over), curious to see if the rest of it is as well. Been a fun trip in to the cam world from just turning handles though.

Go for it, and take a video!

Use trochoidal milling and you can go really, really deep.

Example here: Estlcam Trochoidal Milling - YouTube

That is what F360 will use in adaptive depending on feature. I have done 6mm doc with it on the internal features, for that slot it is a lot of wasted move time though. Have changed strategies to make a second setup be the final cnc setup where I dont slot around it any more, I use adaptive to clear all the material around it. Lets me flip the part and use my smooth faced jaw inserts to hold the part while I clear and finish the other side.

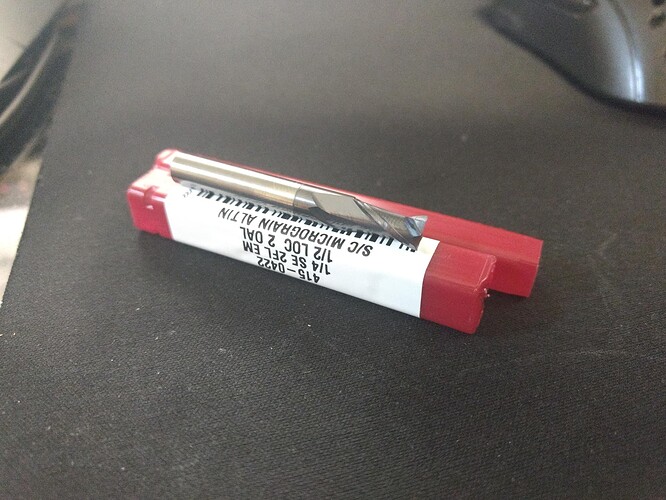

I don’t know if all of you will get what this end mill means, but I am excited to try cutting another material with it

Altin… Going after some steel. Good luck!

Yessir! We will see if it can “cut” it! Feel like I have a good enough handle on the cam side of things to give it a go.

I’m interested in seeing how it goes. My last test with steel had the tool grab the stock and overpower the steppers. You aren’t geared down at all, right?

I think all that metal in your Z will help. Watching the slow mo, i think it pulled the entire core around, and it might have been the bouncing that did it in.

Still the same 16T pulleys, I am running a 24V psu that helps the torque curve out. Also moved to .65Nm steppers on the Z and Y. Was losing steps on the Z during the CNC race testing and realized I didnt unsimplify the Y axis figures for when the carriage is at the ends of travel, .65Nm gives me a little more margin to work with there.

Definitely not expecting to hog the steel out, but we will see what it can manage.

So I played a little more with my feeds today on a 2 flute end mill still (1/4" dia, 3/4" doc, variable flute). Who wants to guess what feed rate I got up to doing an adaptive path 3mm deep 1mm step over? I did take a vid that I will get uploaded today/tomorrow.

The answer is 224 ipm where I started getting some bad chatter, but it did hammer through at 194 ipm doing 3mm doc with a 1mm step over! Definitely need to give the 3 flute I have a shot since it is shorter than the 2 flute and a bit stouter. Never thought I would be zipping along like that in aluminum!

That is very impressive. Nice work!

How hard would it be to make a 35mm tubing version? I was given some nice stainless steel tubing a while back but it’s 35mm OD and I haven’t had time to design a CNC around it. However, if it’s kind of easy for you I’d really appreciate it.

Unfortunately going that much larger would be a partial redesign of the X carriage itself and would likely need special caps for the uprights.