That’s a possibility, it’s not impossible that some issues were coming from noise or from over compensation due to steppers fighting each other (haven’t thought of that one before actually, good point). But I got them to work at some point, only thing I needed to do was to tune the PID, which was not possible without some very complicated firmware edits, using the manufacturer firmwares which didn’t work.

I got them replaced with version 1.1 instead of version 2.0, but I had no time and frankly no motivation to give it another test.

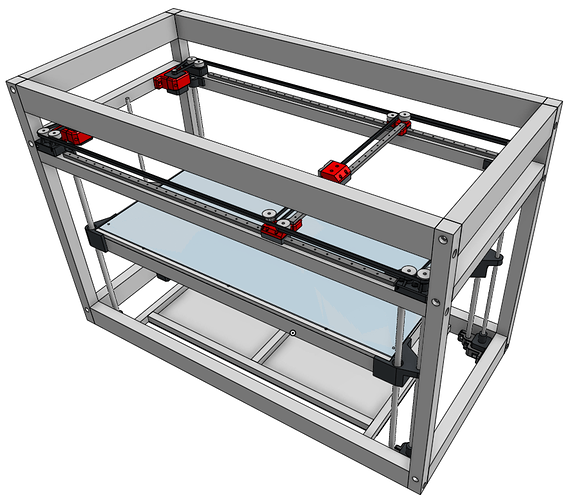

Over the past months my machine has printed a lot of stuff, I’ve used more than 20 kilos of plastic printing things for work, many jigs, parts for machines, test or assembly benches parts, etc. Goal was to test the printer’s reliability.

It helped tremendously my career, I’ve now become officially engineer in my company despite not having any engineer degree, and to be honest this forum and the MPCNC have not been strangers to this: I’ve learnt tons of stuff from building my first MPCNC and from you guys on the forum so I really thank all of you for that, and especially Ryan obviously!

Too bad we can’t share a beer to celebrate that, but maybe someday, I hope!

I have to say I’m impressed by how reliable this printer is so far, I don’t even recall when was the last print failure I had, and if I had to guess it was probably not machine but human related.

What is even more impressive is that it still works perfectly fine despite lots of broken parts. It was a bit hot in my garage over the past months, and my stepper motors current is set up quite high, so the roller parts did melt, also the print head broke in several places due to some mistakes I made.

But it still carries on and prints just fine, this thing is just great, I think it deserves the name of Big Ox Jeffe gave it, it seems just unstoppable.

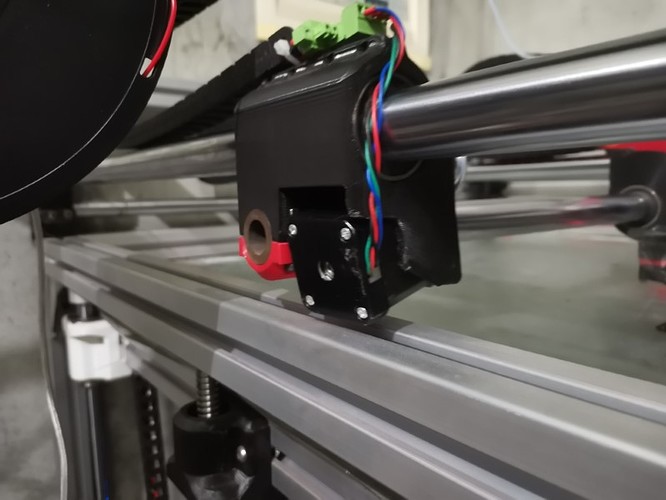

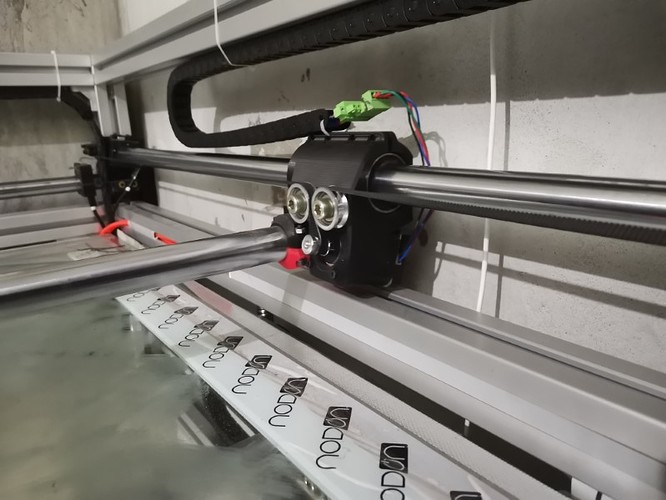

Just look at how deformed the rollers are now, seems like the motors will fall off any second XD

Also a proper repair on the print head, using tape, beautiful work:

Anyway, still works incredible. No problem whatsoever, I love it.

Also, maybe some of you remember I was building a new electric motorbike and printed the battery covers using this machine. Well, on the good news side, the motorbike was almost finished and it is very, very powerful. On the bad news side, I crashed it very hard at 100+kph. Amazingly, both the bike and myself survived with some very minor injuries, just some big scratches and bruises (now I’ve recovered completely so everything’s fine).

And well, those battery covers survived incredibly well. No cracks, they are still in one piece. Remember that this is just PLA. The bike slided on the covers for a bit less than a hundred meters, but as you can see, they are really, really tough, doesn’t look like such a violent crash at all:

So yeah, PLA’s great and you can indeed 3D print some very tough stuff with it!

Sucks because I had just finished the paint of the frame and I think it was looking great, now I’ll have to do it again. That thing is a beast, it has some pretty crazy torque, around 30KW of peak power, and it weights only 110kg, it’s so fun to ride! (well, as long as I don’t crash it obviously):

Anyway, I’ll start by fixing my printer next week with improved rollers and then I’ll work on fixing the bike, luckily the damage is very minimal. Next the plan is to replace the PLA battery covers with carbon fiber ones, I’ll have to print some very big molds for that.

Also I need to make myself a new print head with a 0.4mm nozzle to try and print some large, high definition parts from time to time.

I hope you it works out in your favor in the end.

I hope you it works out in your favor in the end.