Hello Everyone,

As some of you probably know, I already made a weird MPCNC featuring many, many mods.

See here for those who don’t know what I’m talking about: My MPCNC made in China

Anyway, after a few years of good service, it was time to make a better version of it. It was working fine most of the time, but it wasn’t reliable enough for my taste, and some things really bothered me, in particular the fact that it wasn’t really square to begin with, due to inaccuracies while building the frame, and also the fact that wood is not the most stable material regarding temperature or humidity variations.

So I started working on a new design. This one has litterally not a single part in common with the original MPCNC, I had to start entirely from scratch. The only things I’m keeping are the tubes, because I already had these in my shop.

I wasn’t sure if I should post it here since it’s basically not V1 design at all, so it’s kinda off topic in a way, but, well I thought I’d share it here because I like the community and it will still somewhat look a bit like a MPCNC because of the tubes and corners.

The goals here are multiple:

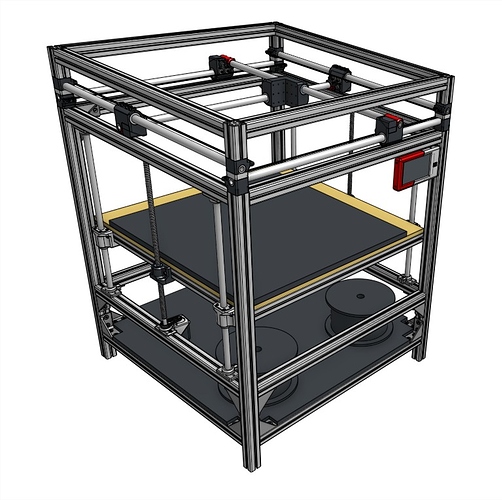

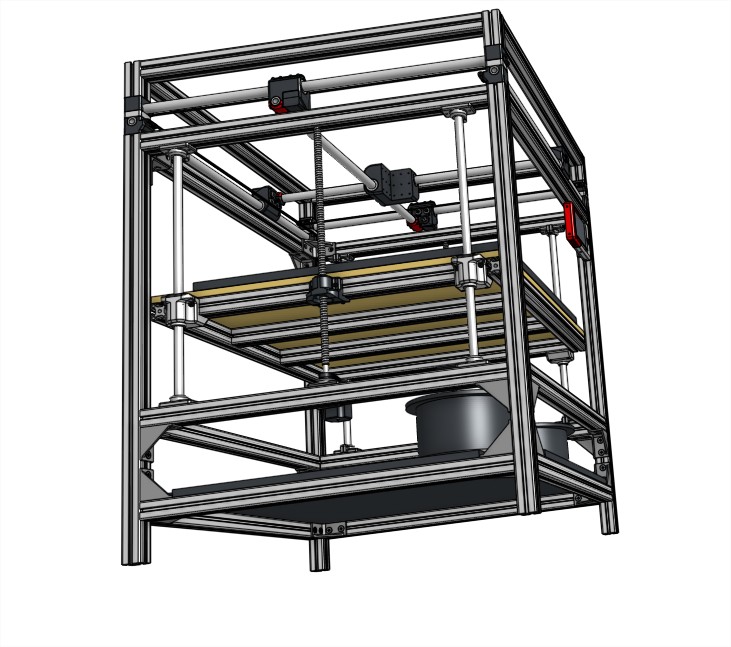

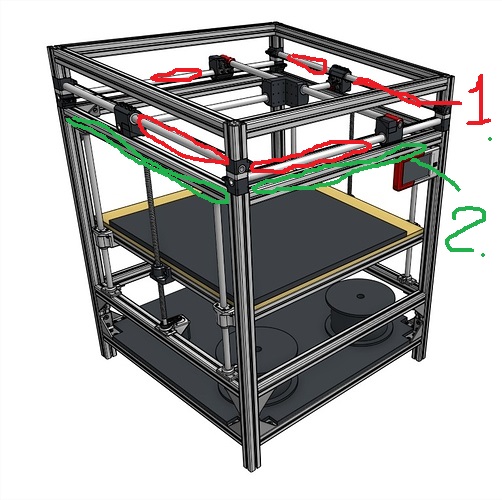

-Have the most possibly rigid gantry system: that implied ditching the Z axis from it. I tried several designs including 4 tubes instead of 2 on Z, semi opened linear bearings, linear guide rails and other systems, but it was just too bulky, complicated and created other issues. So I decided to have only X and Y moving the gantry

-So, as you guessed it, Z will be a moving table, actuated by two or three 16mm ball bearing high precision screws. I’ll first build it with only two screws and add the third one later if it turns out to be necessary.

-Aluminum extrusions frame: I went for 4545 profiles, 4040 was a bit too small to accomodate for the 25mm tubes, and 5050 was really much more expensive. There’s about 22 meters of extrusions in total.

-Duet2 Wifi control board with a huge 7 inches touchscreen. So, unfortunately I won’t be able to use Marlin anymore on this machine, but according to many peole this board is really awesome so I’ll give it a try.

-Better cable management. I’m still not decided yet, but I’ll try to make a better job at cabling, using some lighter stuff since I won’t use plasma cutting on this machine. My only requirements here is that it must look super clean and be easy to disassemble. If possible, off the shelf components, wiring is tedious so I’d like to be lazy on this one.

-Simple tool changing gantry. Right now I designed a system that allows to swap tools relatively easy manually, but later on the goal will be to automatize it.

-Using multiple extruders for color and material changes. I never tried this, but this new platform will be perfect for it.

Main goal is really to achieve very reliable printing at relatively high speed and high accuracy. I want it to be a no brainer machine, launch a print, go open a beer and come back later, if possible drunk, to pick up your print.

Anyway, First thing I had to do was a bit heartbreaking since I had to tear up entirely my good ol’ MPCNC. After so much time and effort invested in it, I felt a bit sad.

But this will not be going to trash anytime soon, the plan is to convert it to plasma cutting only. I’ll build a water table for it and hopefully it should cut metal before the end of the year.

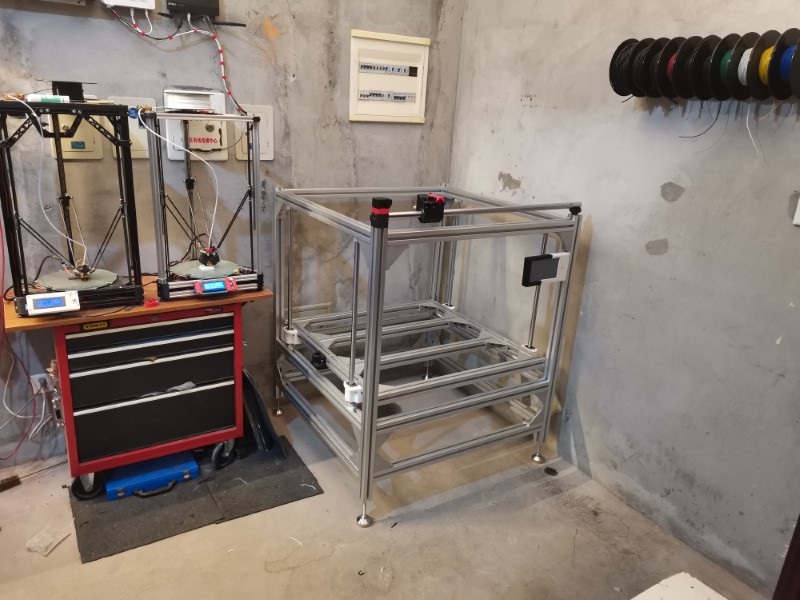

Later yesterday, I received all the necessary hardware for building the frame:

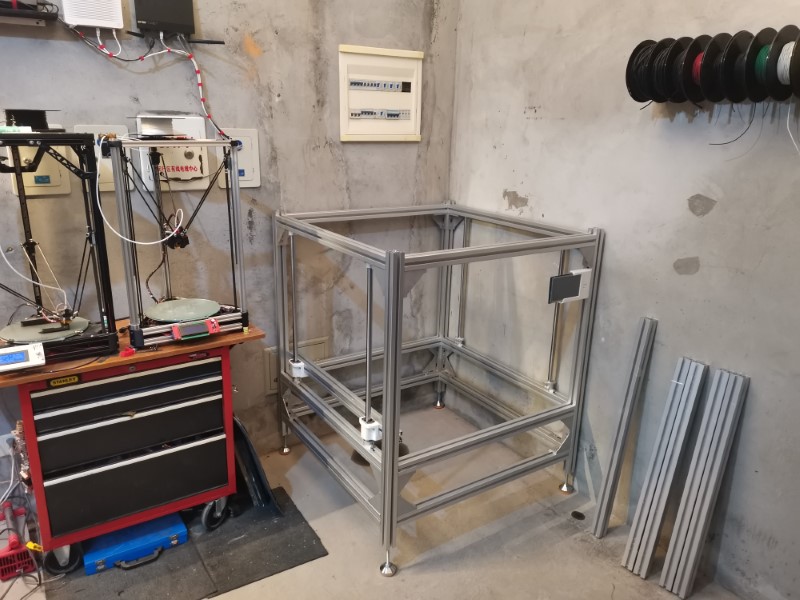

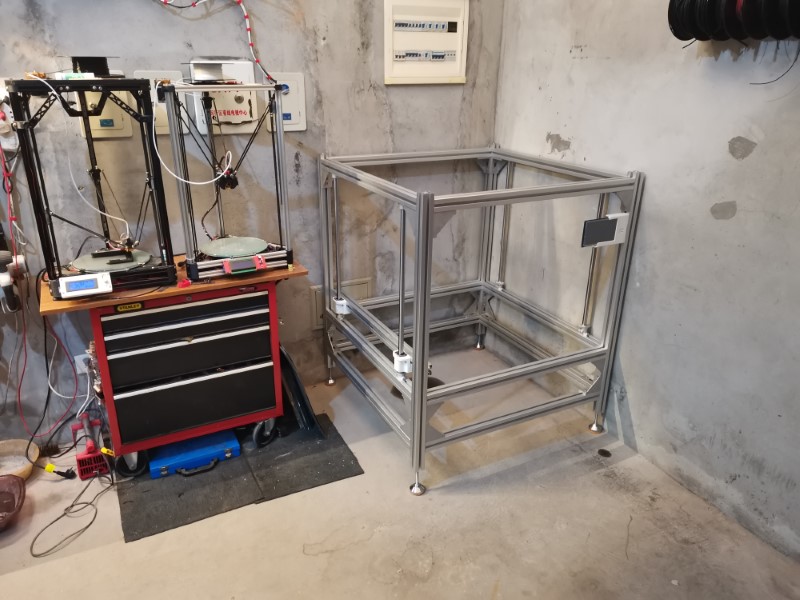

So I started the assembly, which is basically lego, relatively easy to build:

Installed the linear guides for the bed: Some heavy duty 20mm rods with linear ball bearings. I was very pleasantly surprised about how rigid this assembly was. I was not able to feel any play whatsoever lifting one side of the bed frame, the other side followed pretty much instantly. I wasn’t able to twist it either. This is very encouraging because this was the biggest fear I had with this design, now I’m pretty confident the bed will be rock solid! Total Z travel distance will be around 600-700 mm.

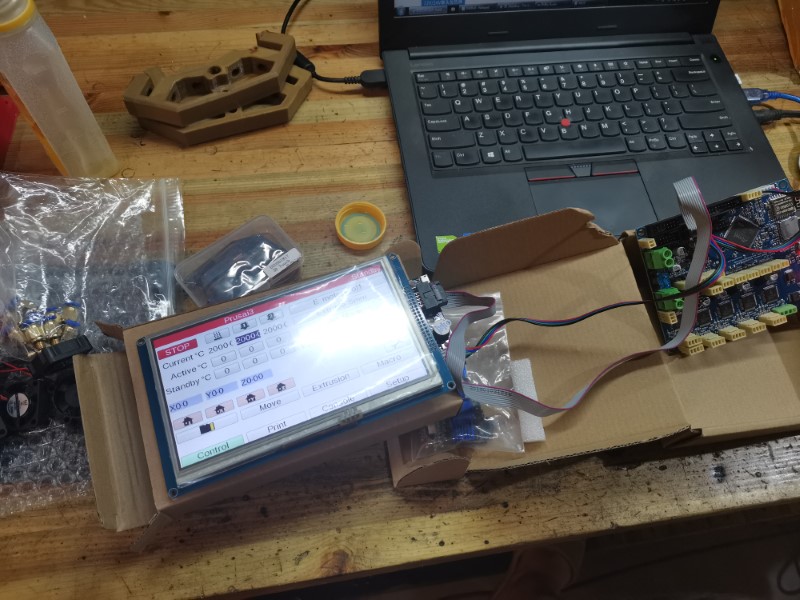

Adding the screen just to see how it’ll look like. Currently printing an enclosure I designed for it so there’s just half of it at the moment:

I tried switching on the Duet just to make sure it worked fine (since this is an expensive board, didn’t want to wait until the machine was finished to discover a potential issue). The screen looks amazing and is quite reactive to the touch. The Duet can be controlled over wifi by a computer, a tablet or a phone, a friend told me later that the screen wasn’t really necessary, but, what the heck, it looks so cool!

A few more pictures of the beast:

It is really sturdy, this thing doesn’t move at all. Haven’t checked the squareness yet since I have to install the linear bearings on the right side before, The white supports for it are being printed right now.

Footprint is a lot smaller on the X axis but a bit bigger on the Y axis than my previous machine was. But in the end, printable area should be bigger on all axis, I plan it to be around 800x800x650mm or so. It is much more space efficient than my previous version, because the wooden frame was really massive, so that gives me a bit more space in my tiny, overcrowded workshop!

Now I’m printing the other parts and trying to make decisions for the stuff I haven’t purchased yet, like the cables and a few other stuff. I’ll keep posting the progress here if it’s not considered too much off topic, so stay tuned!