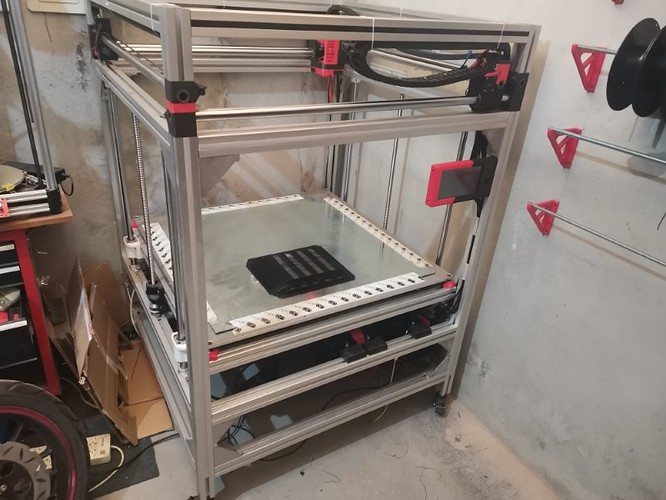

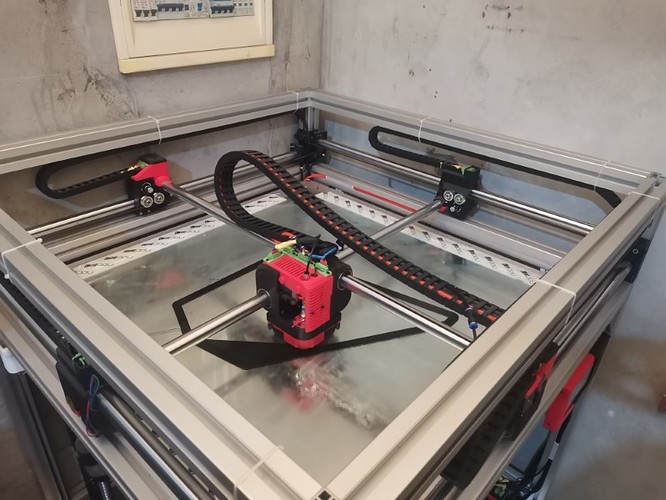

Well, to be honest I have no real good pragmatic/functional reason for this, I just really like how clean and professional it looks with everything contained within the frame instead of having the spools exposed and a filament wobbling around the print head. Plus it actually works really well so I just need to make it a little bit easier and that should be enough. Actually I had an easy idea I’m gonna try: the bowden tube is only useful for curved sections, I could just entirely remove it for every straight line and it would work just the same, while making filament load and unload much, much easier.

So I think I’ll do that instead, that’s the easiest possible solution since it only requires me to print a few little brackets to attach quick fittings.

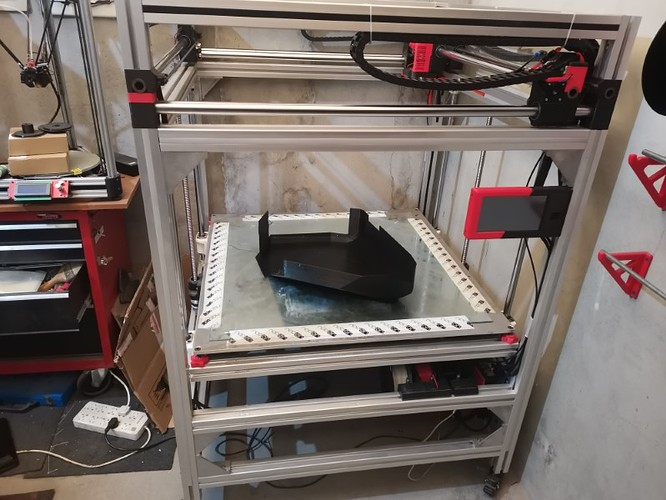

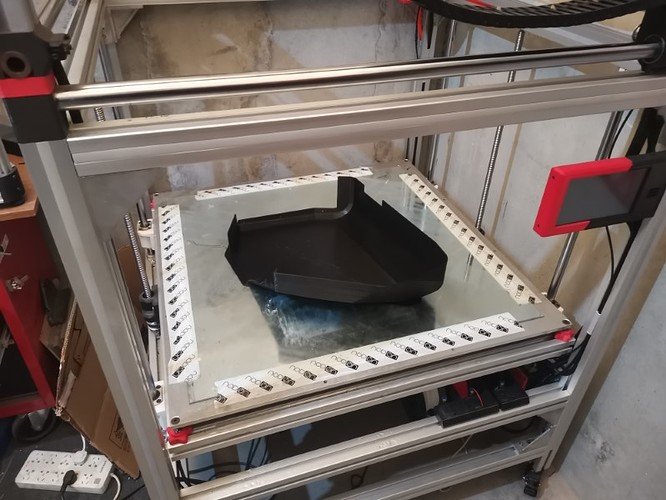

Anyway, the printer is super reliable now, I can’t be happier with it. I printed a lot of stuff and made some relatively long prints.

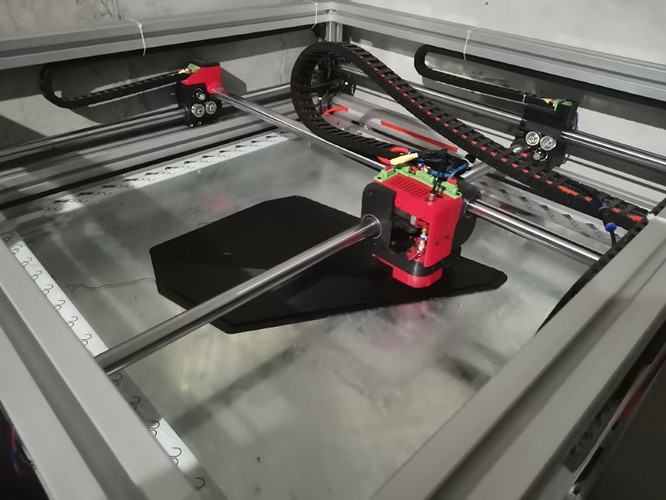

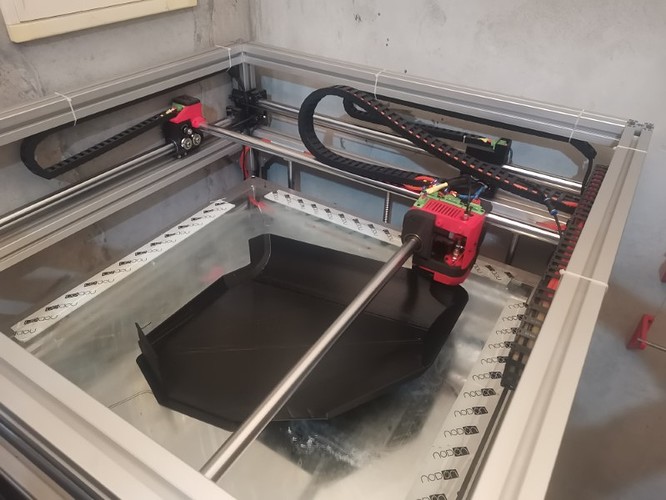

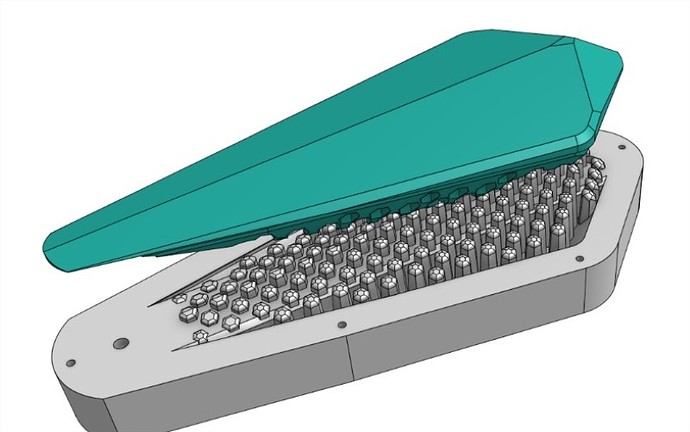

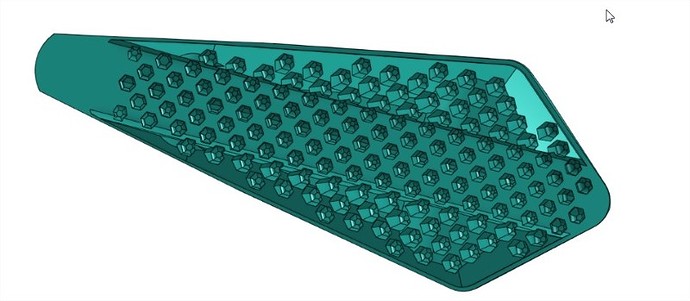

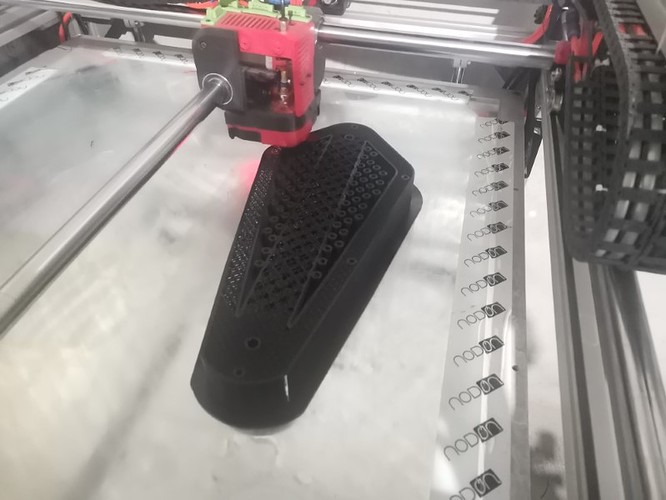

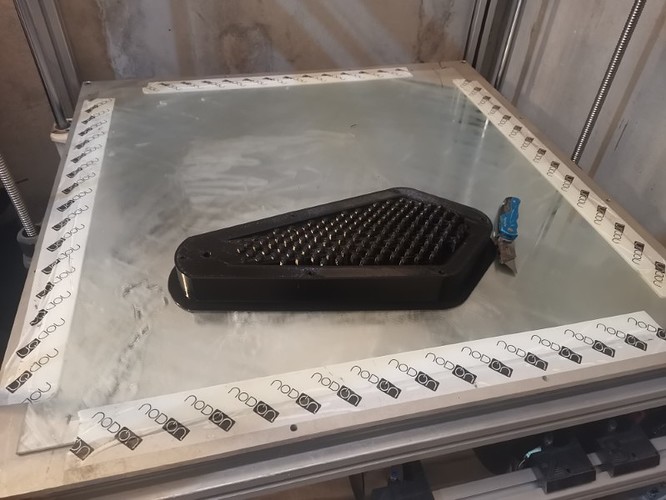

This one for instance took 9 hours, it doesn’t look that big on the picture but it is actually not a small part at all, plus I tried using a weird infill that took a bit longer to print:

This will be the main support for my bike’s battery. I’ll carbon wrap it later but it is really, really strong already.

It printed absolutely perfectly, no warping whatsoever, perfect bed adhesion, the layers were consistent, the first layer is always a success, the top layer is smooth as silk and once the bed cools down the print just pops up without drama… Only thing I could tweak is my initial layer height since I have a bit of elephant foot symptoms on the first three layers, but other than that it’s just spot on.

I’ll also have to change part of my watercooling pipes since I’m using some very soft natural latex on some parts and it doesn’t age well, I have a few leaks. I was expecting that, this was just some random scrap I had layin’ around in the shop. I’ll replace it with some higher quality stuff.

Also have a few little things to take care of, nothing important, just some finishing touches like cleaning the wiring, printing a few brackets here and there to replace the ugly zip ties, wiring the screen again since it’s not connected since I’ve redone my wiring, etc.

Last time issue with the filament sensor was just that I wasn’t careful and cut the signal wire… so once I figured that out that it was an easy fix. Now I have lots of confidence in this machine, no failed print whatsoever, nothing broke or overheated, perfect! Printed two more kilos of PLA since then, not a single issue.

All this hard work paid off, this machine works great!

One improvement I’ll try to work on soon will be to add a little webcam on it. The Duet web interface allows to do this, so it will be very useful for me to monitor from a distance that the first layer did go well and make sure that nothing catastrophic happened during a print. I just need to educate myself a little to see how to do that.

I’ll be able to check the printer easily with my phone, that would be super convenient.