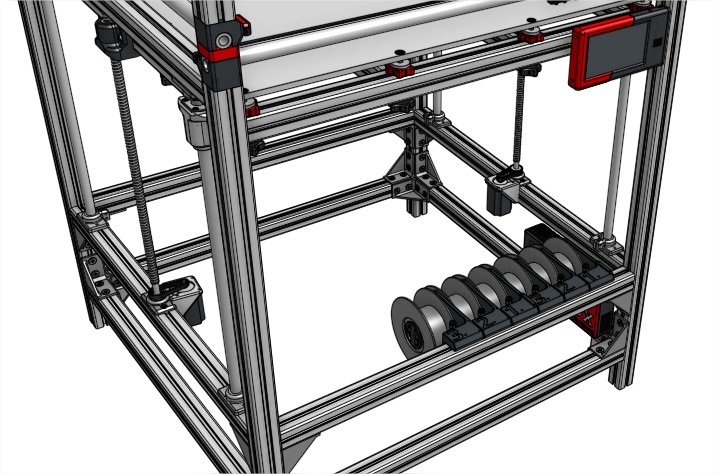

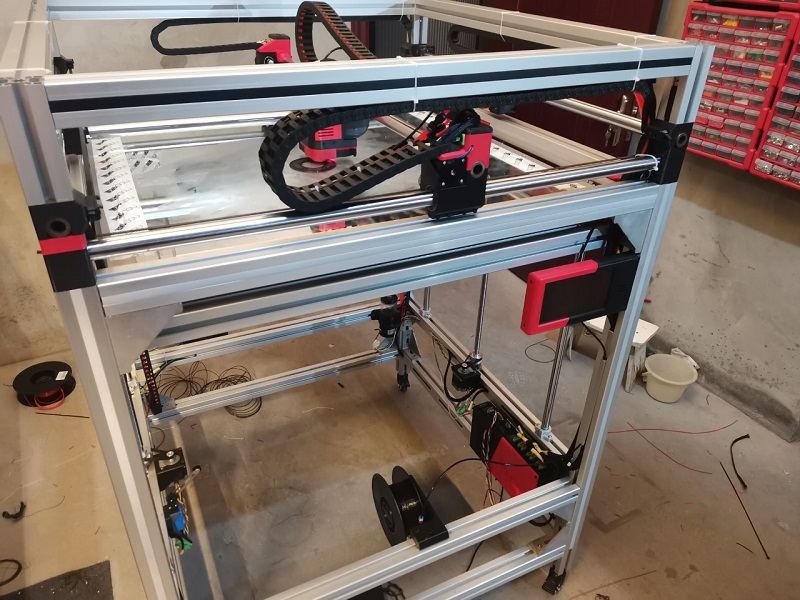

Ok, thanks Barry. Yeah, that’s what I’m doing also too, but with only two Z motors I can only adjust one one axis.

So I’ll just add one more later.

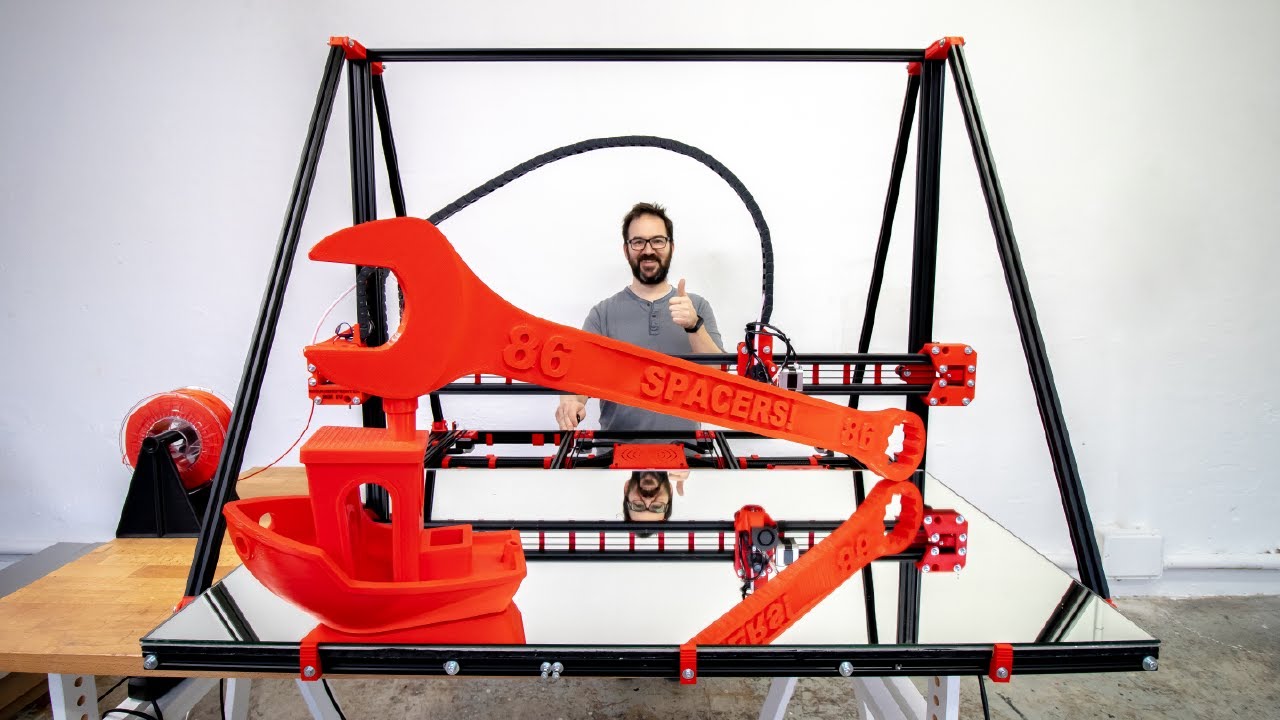

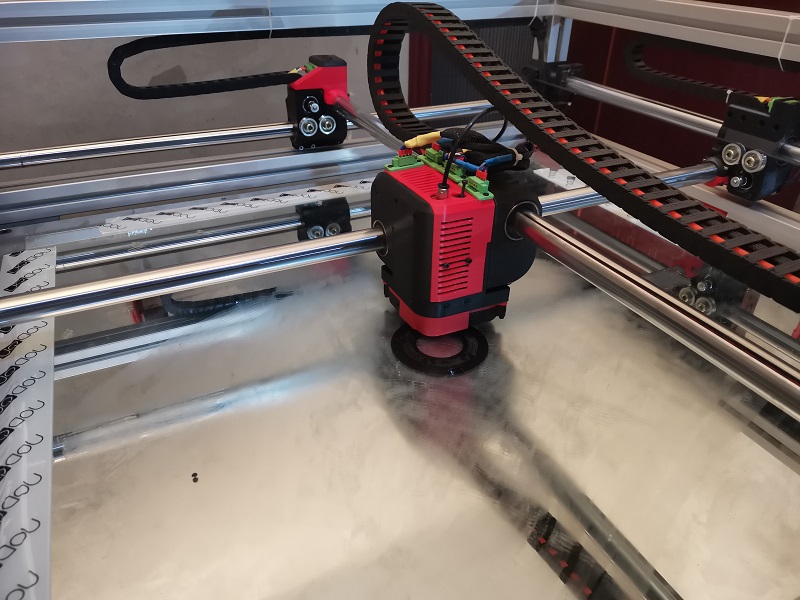

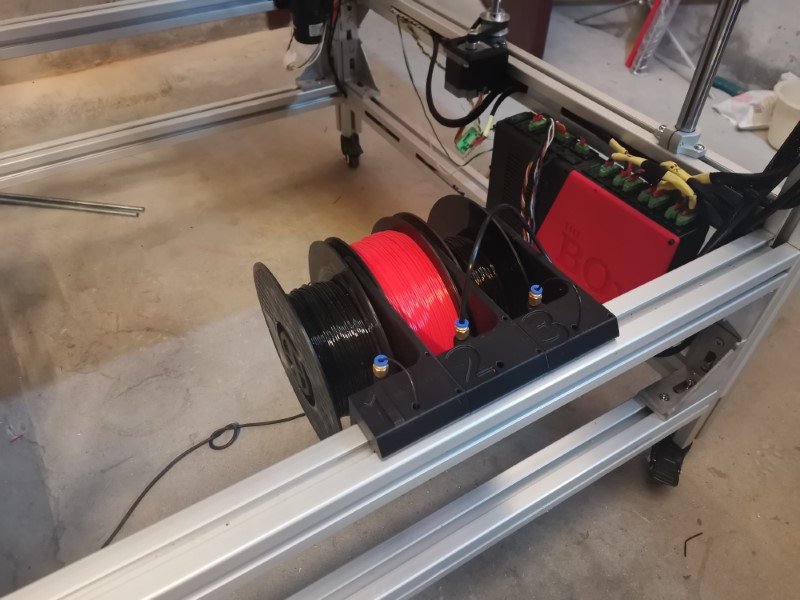

Good news, the BOx seems to be reliable so far. I’ve already used one kilo of plastic without failure (well, without machine failure, because I stupidly failed a print because I ran out of filament… I really need to install that damn filament sensor!!)

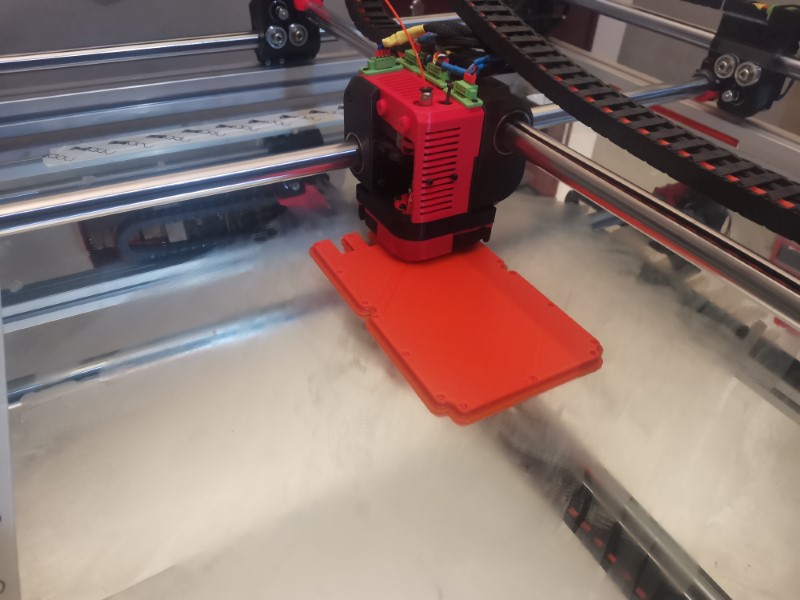

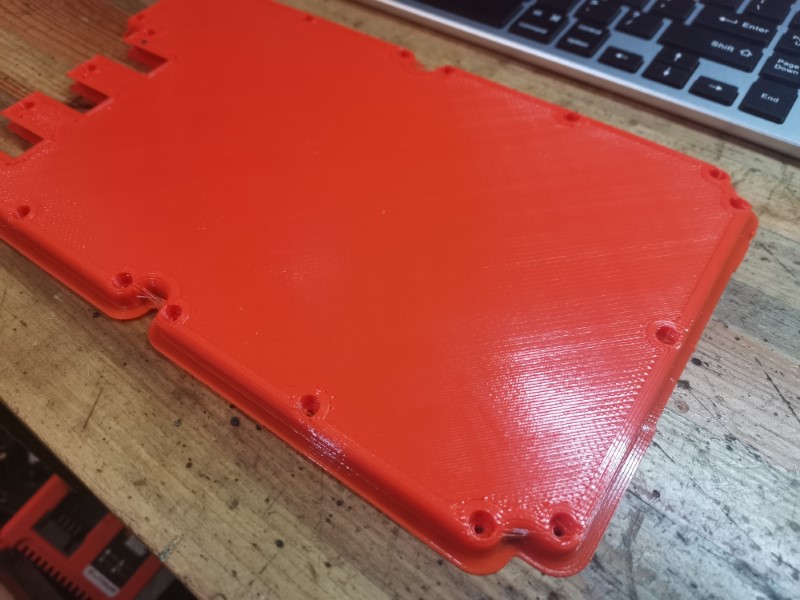

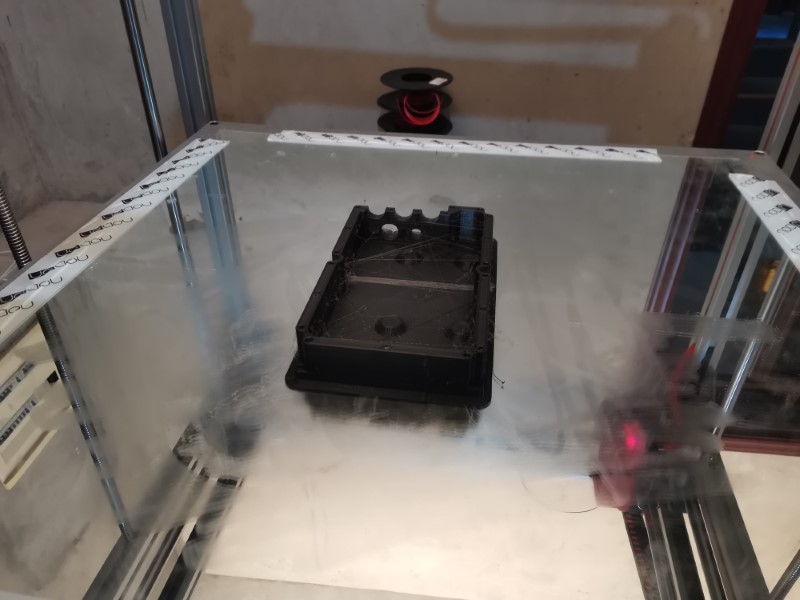

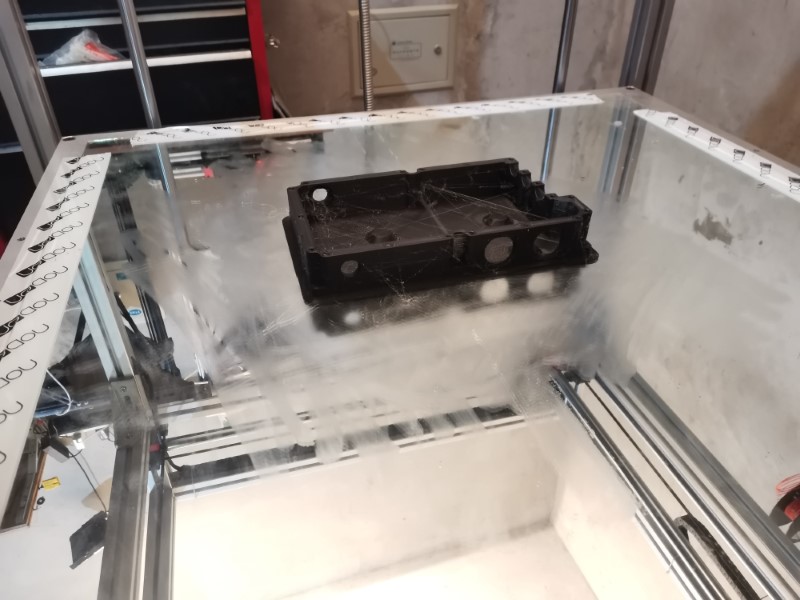

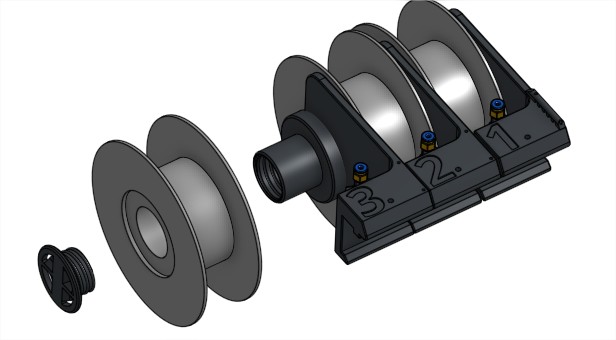

This part was supposed to be the lid of my battery monitoring system’s box. It printed really well until it ran out of filament. I did try to change it, but after pausing, changing the filament and hitting resume the printer just stopped. That was a firmware mistake that I corrected since so it shouldn’t happen again.

Too bad because the result was really, really good. The pictures don’t do it justice but the top layer is really smooth.

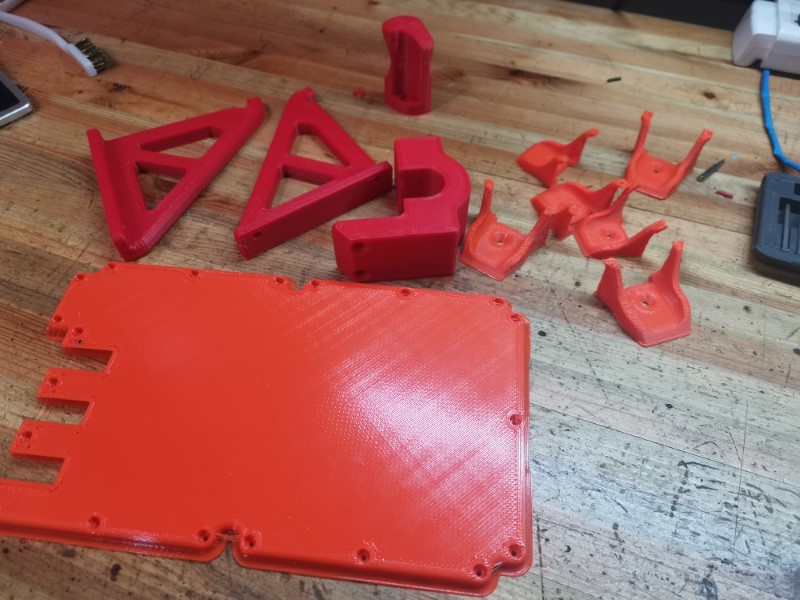

Some random stuff I printed also:

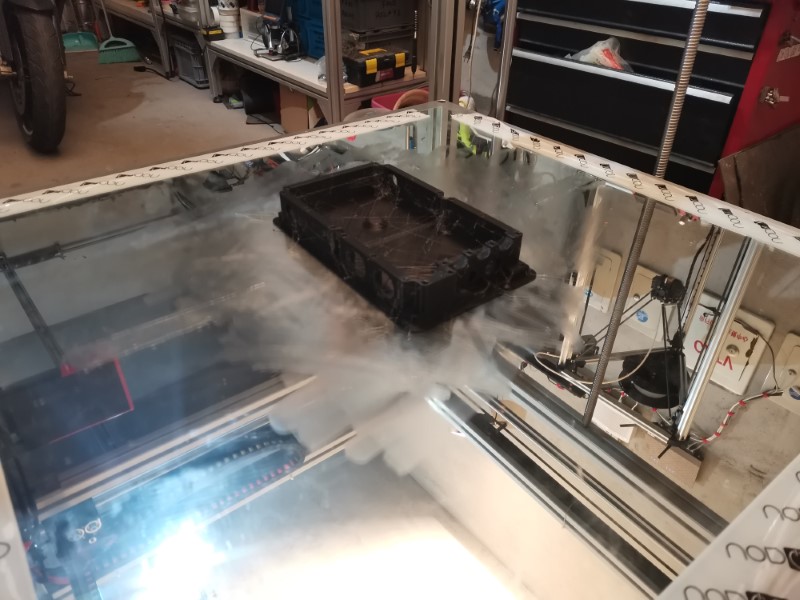

And now for the longest print yet: the battery monitoring system’s box. It took a bit less than 7 hours, and even if I didn’t really want to do that just yet I did let it run overnight. Well I didn’t really sleep well and I woke up a few times just to check, but that did worth it in the end.

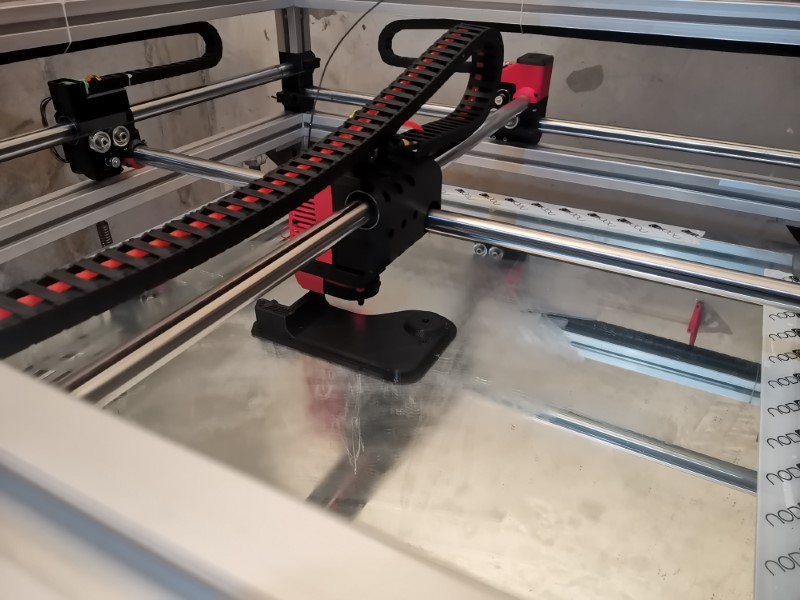

This part printed very well, no issue whatsoever. It looks like there is a crazy amount of stringing, but that’s actually extremely thin stringing, much thinner than a hair. Something like a spiderweb so it’s super easy to remove.

After the plate cooled down it almost separated by itself from the glass. And best of all: no warping whatsoever, the part is dead flat! I always had a bit of warping on such kind of parts before so that’s great to see.

The quality is good overall but I can surely do better, For instance my Z offset isn’t well dialed in so I have some elephant foot, I also need to tweak the linear advance.

Last print quality issue I have that bothers me a bit is ringing after a suddden direction change. The head is heavy so I guess this is a byproduct of high accelerations + head mass + slightly elastic belts. I’d like to avoid lowering the acceleration so I’ll start with tightening the belts a bit more and see how it goes.

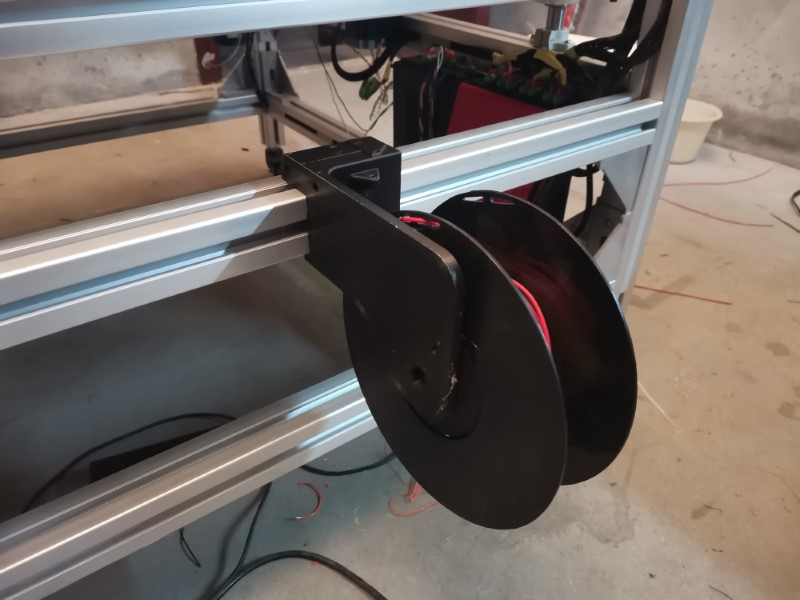

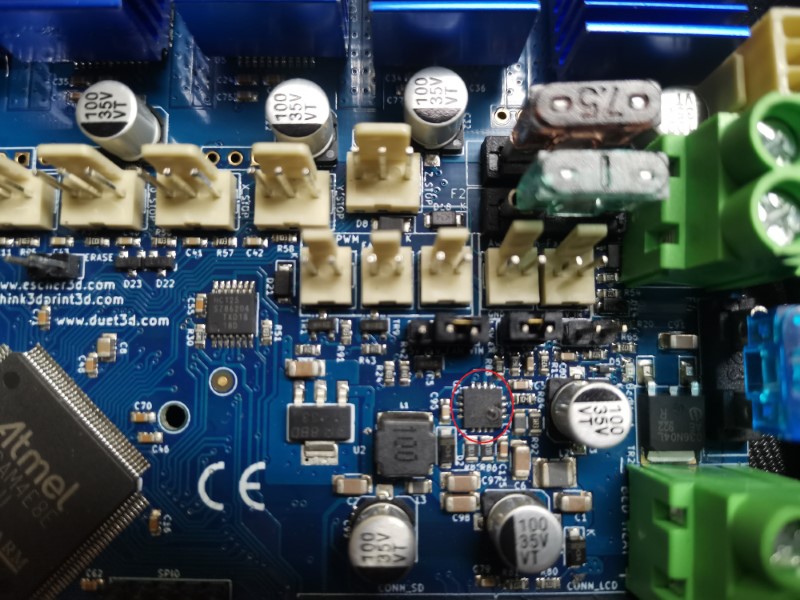

I also found a simple fix to my extruder issues: I just added a little fan. Turns out the stepper was getting way too hot, which made the filament soft in the extruding push gears. Since I added this fan, the stepper stays at a more reasonable temp and now I have no issue with it anymore. So I guess I’ll stick with this until something warns me to do otherwise.

Anyway, the point is: I think I’m on the right tracks with this machine now, it’s more and more reliable so it will be time to start tuning the print quality up.