Ok so I’m starting a major update on my machine, trying to convert it to closed loop stepper control.

On very rare occasions, I did see some layer shifts. I know that under some very specific conditions, a certain type of small infills are able to make the printer slipping a few steps. So far, the only solution I had was to dial the speed back, but obviously that’s just lame.

So now I’m going to try and experiment with the bigthreetech S42b v2.0 closed loop steppers, in order to see if I can achieve higher speeds while improving the reliability, without sacrificing print quality.

Sounds like a lot to ask, but I’m curious.

I’ve seen a few videos on those steppers on youtube and they seem to work really well, so hopefully that’ll be the case on my machine too!

Plan is to start using them on X and Y axis, and then later on Z if it turns out to work fine.

Basically anything but the extruder (I do think it is still nice for the extruder to be able to skip step to compensate for problems or bad calibration, if an extruder starts skipping steps there’s usually a good mechanical reason for that to happen, so keep applying more force won’t solve the problem).

Anyway, I received 4 of these motors and quickly tested them:

They seem to work nicely, the screen is kinda cute. First thing I did was to calibrate them, which took about a minute (the motor will turn very slowly until it ltells you that it needs to be reset). Then I checked the rest of the menu, which allows you to chose microstepping, maximum current, invert direction and some other stuff.

Pretty neat.

I just wish there were some kind of test menu, where you could ask the motor to perform some kind of sequence (one full turn left, then one full turn right for example), just to see if everything’s in order.

not very important though.

The only issue with these steppers is that, instead of 4 wires, they need 6 wires. So, yeah, you guessed it, I have to redo my wiring for the billionth time… But I’ll also have to redesign and reprint my electronics enclosure as well as a few other parts. So that’ll be a lot of work actually.

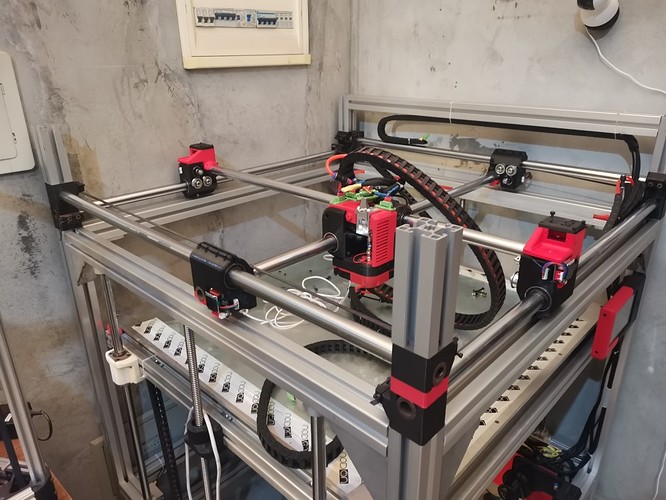

I removed the old motors and installed the new ones:

I’ll prepare the wiring this weekend. I’ll also have to figure out how I should connect that to my duet board and how to modify my firmware. In theory, This extension board combined with the duet allows me to go for 10 axis!

In practice, I’m not sure whether Reprap Firmware allows for stuff like autosquare. If it does, then I’ll use auto square for X and Y, then add a third Z axis (it’s something I planned to do for a while now in order to get the bed perfect), and I’ll still have 3 axis left for 3 extruders. Would be a hell of a machine, tha’t for sure.

But I need to get educated regarding what this would imply in terms of firmware mods, I hope it’ll be simple enough.

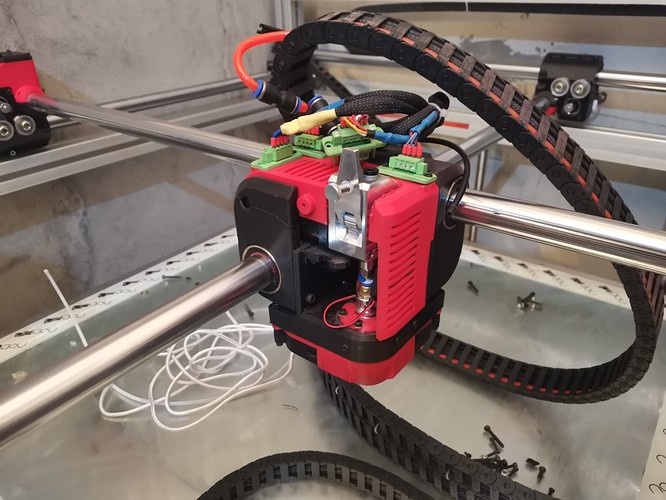

Also, I took this opportunity to try fitting a beefy aluminum bondtech style extruder:

The previous extruder I installed worked well, but it was a pain in the ass to load the filament in it, it wasn’t well guided inside so it was really frustrating. This one being geared and full aluminum, I expect it to heat far less (I had to install a fan on my previous extruder motor, otherwise it was getting too hot, to the point it started melting the carriage)

Now it’s time to start making the new electronics enclosure (I’ll keep the current design, just make it bigger)