Ok I’m not sure what I did but I got it to go all the way to the edges on the 3 position level (sorry I’m drawing a blank as to what that’s actually called). I’m still having an issue with it not completing mesh leveling. it will probe several spots then all of a sudden it will go to probe and say probe failed. Usually in the same place but not always. then it will just go to print and its still skipping steps and causing layer shifts bad. I have the x and y steppers at 1000 and its still skipping. I got out my FLIR last night but the battery was dead. Should be charged up so next time I attempt to print something I will see what temp the motors are getting to. the belts feel super loose to me. way less than i run the primo or LR3 at so I cant see how it can be that causing it. Any info anyone has on these issues would be super helpful. I’m at a loss right now.

I think you need to watch it. Really close. Start a print with no leveling and put a finger on the belts or something. Is the pulley loose, are the belts too loose, is there binding on your XY, do the idlers spin freely or did you punch them?. This is not a common issue with any printer, so something is wrong that we can’t point a finger at.

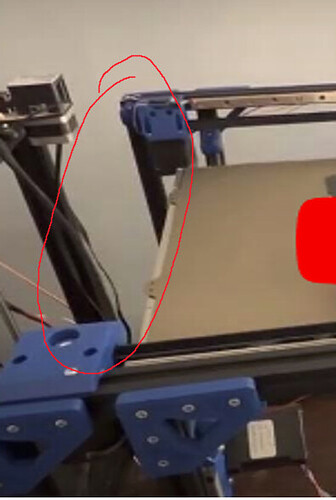

Maybe a couple pictures of the gantry, maybe there is a build issue.

What probing fails The three point of the mesh?

The three point will fail if it can not close in on a level bed. So either your Z belts are too tight, too loose, pulley is loose or your Z trucks are hitting the top Z belt mounts and it can not compensate. You can hook it up to a computer and watch it in the terminal. The numbers should get smaller each time, it might get a tiny bit bigger once but if it can not get it in 8 tries it will error out.

The mesh will only fail if the probe is too far or too close (failed three point).

Thanks Ryan. I have been trying and trying to figure out the cause. I think my lack of experience is biting me the most lol. I put lock tite on the grub screws on all 5 motors. I’ve never had one come loose on any of my CNCs and I don’t believe that is the case here. But I suppose anything is possible at this point.

Here is a video of it trying to level. You can see the skipped steps. Maybe this will give you some idea.

When the machine is off I can move everything around pretty freely. A slight resistance but nothing more than any of my other machines. No tight spots or anything like that.

Could slightly out of square cause the issues I’m having? I have spent HOURS trying to square and keep this thing square but as soon as you look at it its back out again. The sides are all square but looking down at the top is not square and nothing I do can seem to make it right. I’ve been watching your post about the side panels and waiting patiently for you to get them to where you are happy with them. Hoping the CAD for them will scale so I can cut some and add to mine in hopes that will help the square problem

Edit. after posting this I went back to measure and its only off 1mm on the top. Of course I would like it to be 0 but i know that’s not always possible. How much is too much?

No that is crazy. Being out of square is not a big deal…as long as it moves smoothly around the whole bed. If the belts are not on doe s it glide all over…no sticky spots, nothing snagging?

That is super crazy. Look at the two front pulleys, use a sharpie mark the pulley and the shaft and the belt do all three stay aligned?

If a belt skips you hear it skip, and you can usually even watch it happen. When it does that what do the pulleys, belts shaft do?

Are all your idlers free to move?

If you over tighten the screws they will clamp them. If the pulleys and belts are not skipping or slipping, take the belts off. You have a bad bearing or something, that is crazy. You can hear something squeaking. There is a bad bearing idler, rail, something is not moving easily.

Everything was good and free when I assembled it but that doesn’t mean it still is. I will take the belts off and see what I find out and report back. After dinner…lol

WOW…I feel extremely stupid right now. And totally kicking my self for feeling so confident about the grub screws. I was moving it again and looking harder at the y motor pully and noticed that I couldn’t put a mark on the pully and shaft as the shaft was down inside the pully. then after turning it some more I noticed a dark spot inside. took out my flashlight and I could see the grub screws inside. they were completely above the shaft. This whole time I have had the pully on UPSIDE DOWN!!! well I’m going to go eat some dinner and bang my head against the wall for wasting so much of your time. Then ill fix the issue and see what happens from here.

We need a grub screw gotcha badge…those little boogers really have messed with everyone at least once.

You are part of the family now!!!

I completely agree LOL. I remember what I did now. I never put the loctite on this one. I was going to go back and make sure it was the right height after putting the belts on. Yeah I’m just now getting to that LOL

Hey, it could have been worse, I think things will make much more sense now! Glad to find a smoking gun.

Me and you both. Its heating up now to try and print the benchy again. Will report back…

What you have circled is actually the front, I have it turned sideways on my table to access the board in the back. I’m going to end up moving the board and extending wires just haven’t decided where i want to put it yet.

Yea I know, but having it open like that is going to induce some weirdness in prints.

OH, I see, there’s an extrusion a bit down from the top.

That’s one for @vicious1 to explain. I just built it according to the pictures LOL

Convertible ![]()

Have you used a hemera before? If not the retractions are super low, like mine is set to 0.35mm at 37mm/s. I do need to tune that a bit I am starting to get the faintest of strings. So either 0.4 or 0.3, maybe. If you retract like normal 1-3mm benchies look like that.