Well ![]()

This sounds very similar to another story I heard today…

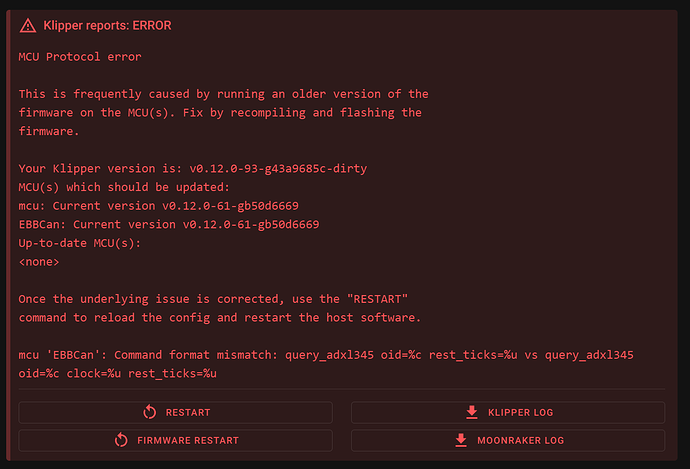

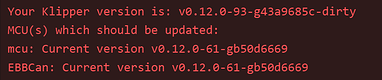

Did you just update to Klipper V12 on the Pi and still had Klipper V11 on the control board?

Yep.

Not quite that far apart

So Klipper has to be fully upgraded in step always?

Its not often that an update makes you update the board. This is the first time I’ve personally run into this. Just got done making the firmware for the board and about to flash it. Hopefully it all goes smoothly LOL

How did you update, via the MainSail or Fluidd WebUI update manager where you can click on update for an easy upgrade experience…

Or did you use git pull or something from SSH/putty/remote shell?

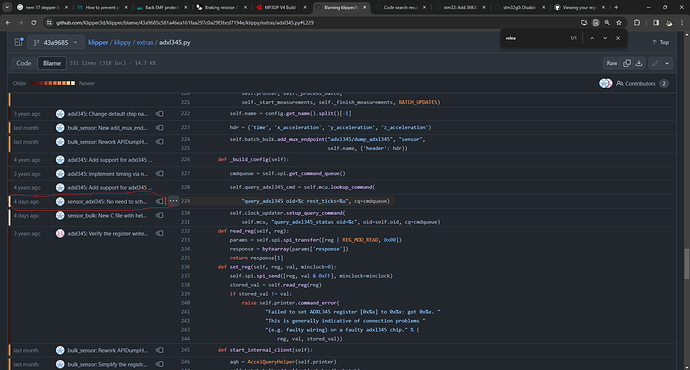

If you did a git pull and don’t want to rebuild and update klipper on your Controller/EBB, then you could maybe sync to earlier code snapshot. Based on the nice breadcrumb in the error message about adxl345 looks like protocol change was made ~4 days ago…

I don’t know how critical that edit, or other edits/fixes made in the last 4 days are though. So, I can’t say which next step is best. You should be able to update klipper via CanBoot Katapult though right, I don’t know enough to know if there’s an easy MainSail/Fluidd Web GUI click a button to update klipper firmware on the CAN Bus devices, or, whether you need to use the flash_can.py script (after doing git pull, make clean, make menuconfig, make, mv …, etc… for each CAN Bus device) ?

This is the adxl345 related edit that’s made your day more fun. Am going to update my Klipper bits very infrequently going forward, and only do so if I’m prepared to potentially need to burn time updating firmware onto the EBB and Octopus as well.

No I did an update in mainsail.

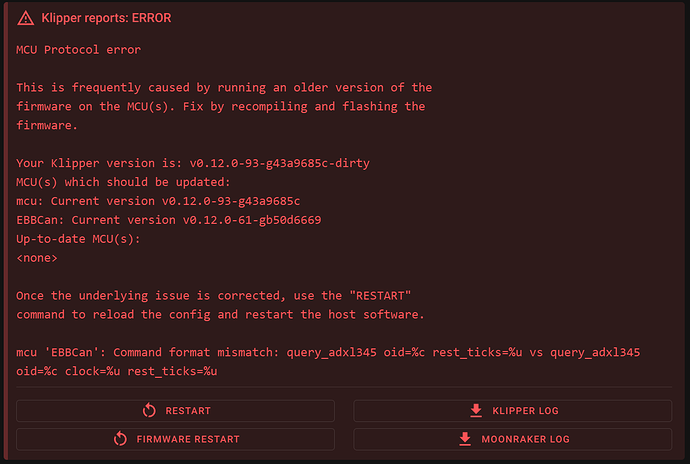

I got the SKR Pro flashed, but its still not happy about it.

For some reason my version of klipper is -dirty. So even with the same version on the SKR without that -dirty its not happy. Going to SSH into KIAUH and see if I can clean up the klipper on the Pi and fix it that way. Then ill figure out how to flash the EBB lol

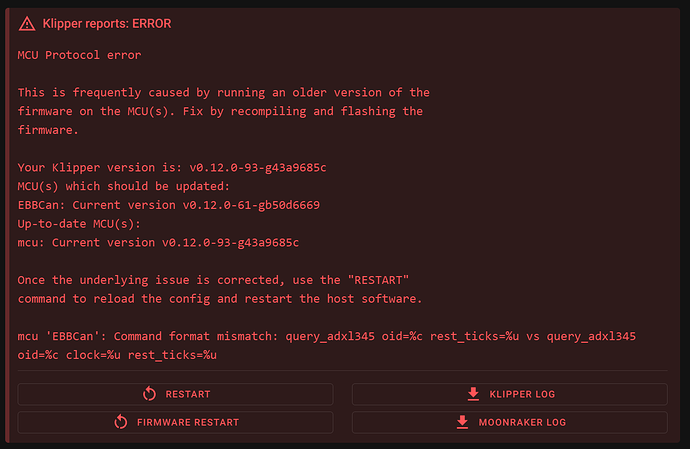

Well when klipper gets dirty the only thing you can do to fix it is wipe it. No idea how it got dirty but I have another SD card writing Pi OS Lite right now lol.

save your configs before your wipe.

Thankfully they are all backed up to github. Any time I change anything I run the backup so its always saved

Back in business! Sure wish they would update this guide. All the commands have Canboot in them and I have to remember to change that to katapult. Other than that I had a successful flash of the EBB36 over canbus so thats good!

@azab2c you get yours running again?

Keep improving your skills and you’ll need to be the one writing a guide ![]()

Do not hold your breath and wait for that one to happen. Everything I figured out last night was from reading what others had tried already lol. I’m not the one able to go figure this stuff out for the first time ever lol

I am in 72 hours non stop printing with 1.2A current - no issues with motors or drivers. However, my question is why you want to bump from 1A higher if you achieved a pretty good acceleration without skipping? I remember you could not print above 1000mm/s^3 that was bad but 5000 is great

Because I’m an idiot that always wants to push for more LOL. Best explanation I can come up with lol. When I got the 5000 it was still saying mechanical issue which I knew because the one belt was so much tighter than the other. And when I got to the good number last night I had the belts way too tight and they wouldn’t hold the 5000 anymore. Running it all again right now trying to get it back to a good spot without having the belts overly tight. Almost there… I think lol

Well here’s were I ended up…

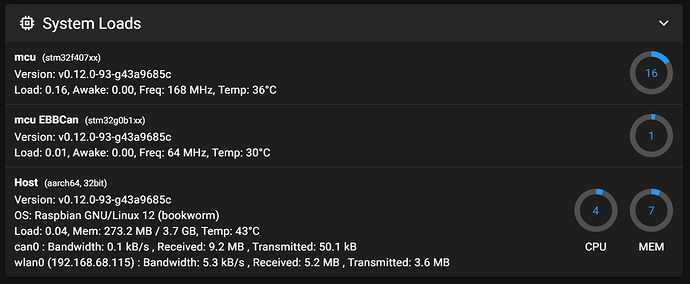

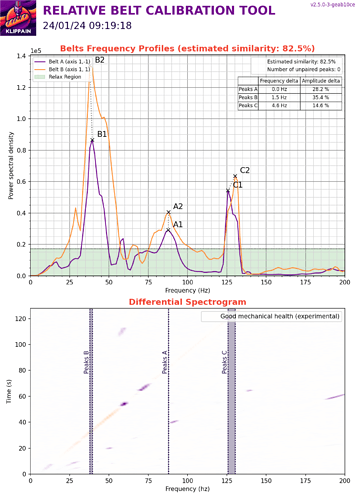

Belts:

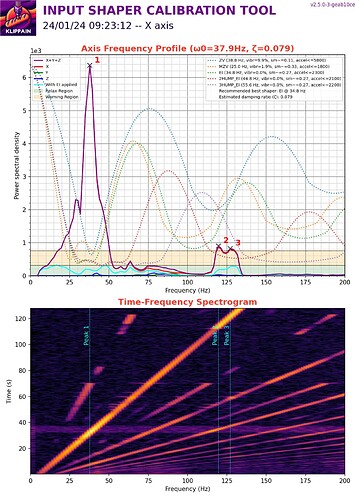

Input Shaper X:

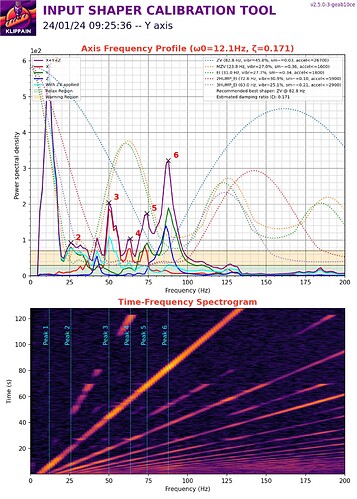

Input Shaper Y:

I still feel like this should be better. There’s something I’m missing that’s causing the extra bumps in there. If any of y’all run this same test on your printers post up the graphs so I can compare please. Give me some ideas maybe lol

I would be looking for a loose nut or bolt somewhere. Likely in the motion system.

Thanks a ton Jonathon!

I’m 6 shattered 1/8" single flute endmills into my aluminum milling endeavors so I have hopefully one last question:

What are you using for plunge speed?