Maybe share a photo so we can see what you’re talking about.

I would love to but I’m not home. Back offshore for the next 14-28 days.

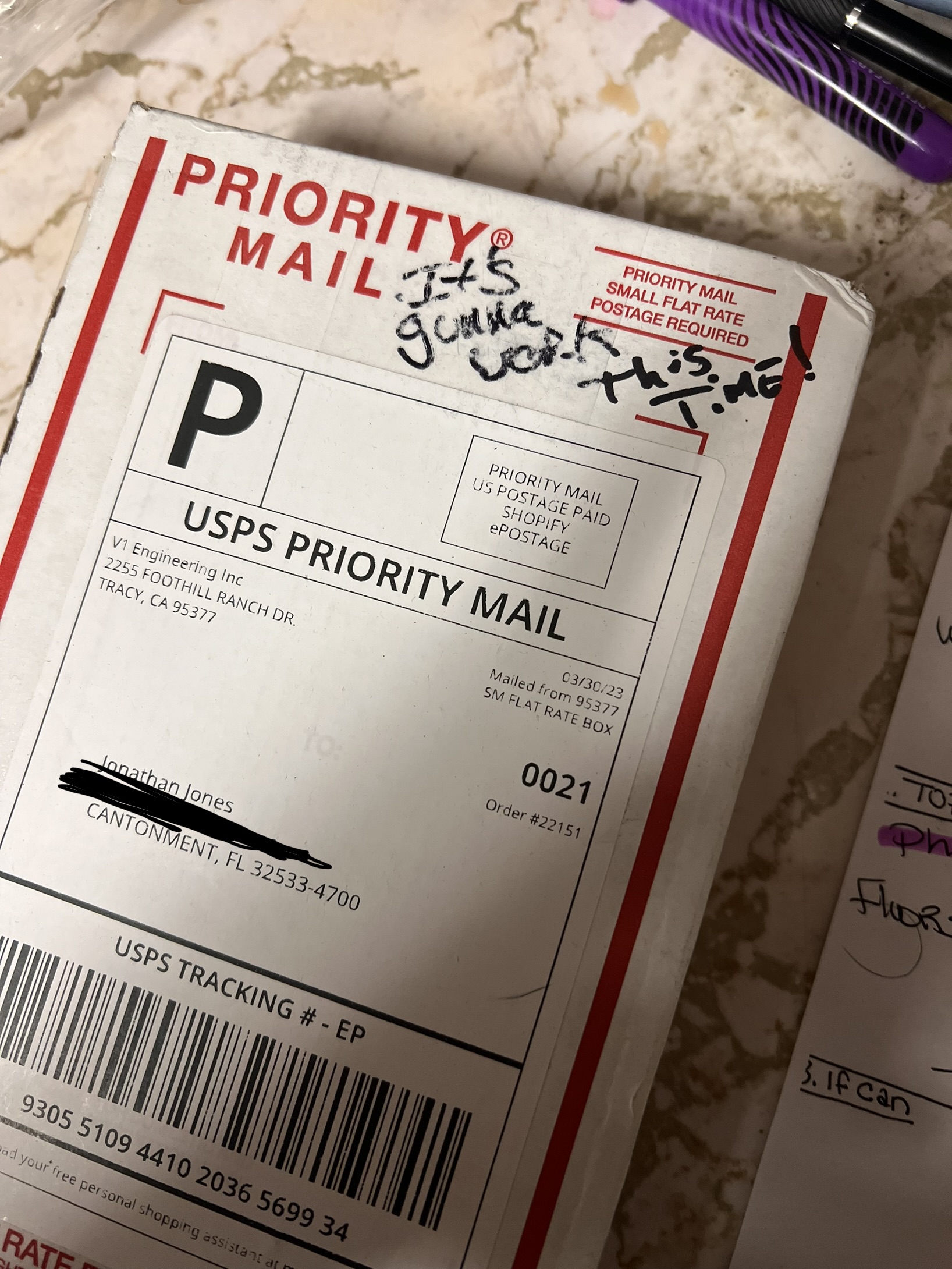

Always nice when you get personalized messages from the man himself! Thanks @vicious1 I sure hope you are right!!! Now just have to wait till 4/26 when I get back home to work on it again. Man this hitch is dragging. But we have been doing some different stuff for a change…

Platform removal…

That is so crazy!

There’s you a crazy one. 8’ from the platform. Parked at night. 30 mph winds. Hell of a cross current and this boat is all manual control. No computer/dynamic positioning here lol. Also that platform deck is 53’ in the air.

That sounds impossible

Lol. You can do a lot with 3,000 hp

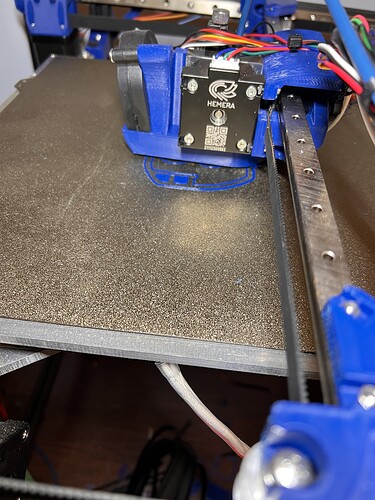

FINALLY made it back home. Got me a lovely box here from Ryan with some new belt in it. I think I’m going to dismantle some stuff and try to get the belts the correct length and also tidy up the wiring some. This rats nest is starting to bother me. Its storming outside today so any outdoor project is canceled lol. Just finished doing some surfacing on the LR3. Time to mess with the printer a little bit. HOPEFULLY this will be the end of all this mess and she will start acting right for a change. I need to go get me some 1/4" plywood and start cutting some panels out. I really think those will help hold it much more square than just the 3d printed corner brackets and hopefully that will help with some of these issues. I wish @vicious1 had a video of putting the belts in and tensioning them lol. I have a hell of a time deciding what’s too tight and what’s not tight enough lol.

Always a fun time. I swear if I want to print just one part it has no problems at all. Put a few on there and nothing wants to stick at all. Makes no sense. Hell just the other day I printed every single zen part except the core in one shot. Took the whole bed. Everything worked great. It’s like the z offset moves around. I really need to get some plywood and build the sides and get this thing cleaned up and wire managed correctly.

Ungh. I feel your pain. This was happening to me until I added the pauses after the bed was heated, before I G28 Z. The bed was moving up and down (buckling) for the first 5 mins or so after it reached temps.

I doubt this is your issue (it might be, but I haven’t seen that anywhere before). I just know how awful it is when your Z moves around. So I feel your pain.

You’ll find the issue though, and at least when it is right, it prints well.

I’ve seen where you talk about the pause. Right now I’m running Ryan’s start code on Super Slicer and it heats up the bed as its homing everything then straight into G34. What do I need to put in the code to have it heat the bed and wait 5 min or so before it ever starts any homing? this large bed at 1/4" thick might need that time to heat soak and settle down. Sure worth a try.

The easiest way is just to preheat it before you start your print. That is a quick test to see if that has anything to do with it before you start adding gcode.

- Try a know good filament. I have gotten ABS and PETG instead of PLA several times.

- Is the heat bed thermistor set right, is 60c really 60c?

- Is your bed clean, IPA or Dawn dishsoap, magic eraser.

- Probe offset right? Baby step get it to slightly too low for this issue to see if that is better.

- First layer speed correct? I use 50% so about 30mm/s I think.

- Extrusion temp right? You can do a flow test where you weigh blobs

- Print fan off for the first two layers?

That is the first things I would check.

The only time I have had temp issues was when I started the print at about 60F and 4 hours or so in the temp starts to drop to about 30f and at some point the parts let go. Other than that I work everyday in a garage with the door halfway open and it gets plenty drafty in there. So in a house it should be fine, unless it has a HVAC vent blowing directly on it.

Preheating is the easiest way to test. Just set it to 60C and ask google to set a 6min timer before you start a print.

If you get consistent results, you can add it to gcode with G4. I added in 20s chunks, IIRC, so octoprint wouldn’t think the printer disappeared.

This where I did my more scientific measurements. The results are pretty clear for my bed. But post processing the serial log file used a lot of my bash scripting skills. You can do it manually, but it is a pain.

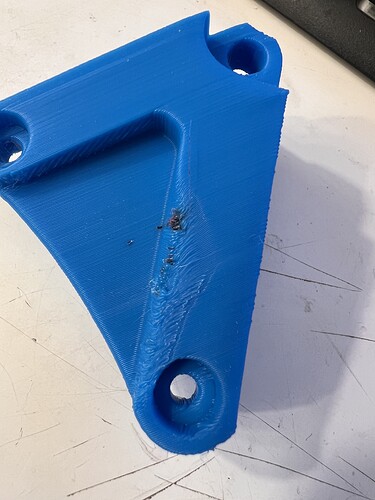

Whats funny is right before this i printed a single part with the same PLA. it had a weird issue but nothing with it sticking…Will attach a pic from my phone…

I will give all these things a try and see what happens and report back! Thank you both for all the help!!!

That is a sign of way too high of an extrusion temp.

That is a slight, overhang, and it was so hot it curled. That one is so slight it should not be an issue. Most of my other parts have much more severe overhangs…or your cooling fan is not on.

Too hot extrusion. I wonder if you burned some filament and it’s stuck in the nozzle now so that you’re not getting proper extrusion. Clean the nozzle. See if that helps.

I’m fighting the same thing right now after switching from PETG back to PLA.

That’s what I thought too but wasn’t sure. Funny thing is I’ve been printing the same temp for a while now but this is the first time in a good while I’ve printed this color. Was printing at 205°. I will back it off to 200° and see what that does. I put the roll in my make shift filament dryer right now so in a few hours I’ll give it a shot and see what happens