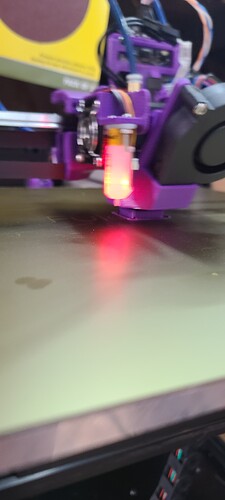

I have my machine up and running Klipper on the Manta M8P using CAN BUS for both the MCU and the EBB36. I was having a chat with @gpagnozzi and told him I would post how I did it for future knowlege.

I used the procedure here: https://github.com/Arksine/CanBoot/issues/61 to get the Manta up and running. A quick note. When you get the CAN ID write it down as you may not be able to see it in the future.

For the EBB36 I used this process: https://maz0r.github.io/klipper_canbus/toolhead/ebb36-42_v1.1.html

Still to do:

- Finish skirts and add fans

- Design bezel for TFT35 SPI screen

- Cut and install ACM Panels on sides and back

- Mount WiFi antenna

- Mount spool holder on back right wall

- fabricate Plexi door for front

- Install lights and camera

- Wrap the bowden and Canbus cable with wire wrap vs the cable ties.

And of course more tuning. I printed a semi successful calibration cube after doing pressure advance and input shaping. It looks great except for the front left corner above and below the X on the front. I many have a retraction configuration issue although it does not make sense that it doesn’t do it the entire way up the cube. I have a feeling it is more from Temperature and that corner is the seam placement so it slows down more when the next move after the corner is slower.