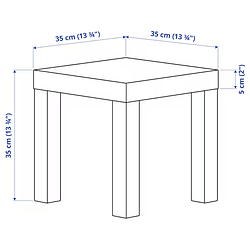

Someone here already seen/made a LACKing no-extrusion Printer? Looks like extrusion free was an option for Repeat v1. Making the v4 design fit a LACK like this Hack a Day would be funny. However, feels like it’d be more hassle than it’s worth.

Taking a quick look at the larger LACK table. But, will be building a mostly stock extrusion frame, will hopefully be faster for me follow what others have built already. Can always Mod later after reaching a working state first.

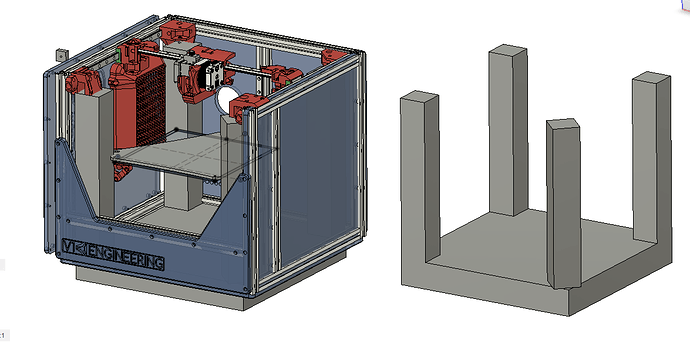

Will oversize the Frame Corner Posts height (like MP3DP v3 / Repeat v1) so a flat surface can be mounted on top. Mainly for heat and finger retention.

Have seen crazier ideas… Milk Crate 3D Printers…