Print directly to the raw aluminum??? Huh. Never once even thought about trying that.

I killed 2 micro-sd cards in PRI just cycling power. It’s meant to be shutdown properly

I guess because I am used to glass beds and don’t know anything else. I bought a magnetic surface once, destroyed it in like a week, and got back to the glass. In combination with an adhesive works really well

I have my entire machine going through a wifi switch. Then it goes through a backup on/off switch on the front of the machine.

I don’t bother powering the printer separate from the pi. Inside the control box, I have a second breaker on the AC line coming in. I still need to add a breaker to the power wire going to the heated bed (mine’s AC powered).

Right now my assumption is that a short in the AC line to the heated bed should trip the main breaker on the machine. But I’m not sure if that’s fully safe.

wifi switch, great idea if it doesn’t glitch like mine ![]()

Fused power switch (10amp or something)? E.g…

I have a fused power rocker to the 24v power supply. 24v goes to the 5v converter for the pi and to another rocker that toggles power to the bed and the octopus control board. Main power stays live for the rpi, but the board and bed can be easily switched and recently that has been helpful without corrupting the pi SD card.

I already have one of these sitting on a shelf. I figure I can just mount it on the rail next to the master breaker.

Decided to give Klipper a try. I am at a very early configuration stage but the moment I added 2209 uart configs motors became much louder than they were before I added config and much louder than running Marlin. Any ideas?

I would assume it is stealthchop, that makes things a lot less noisy.

Thanks Ryan I overlook this option!

Remember me printing at 500mm/s? That was with brass nozzle. Now with a stainless steel extruder barelly keeps up with 150mm/s

I’ve noticed on my TAZ 5 / Genuine E3DV6 hotend that I can pretty much max out the 13mm^3 volumetric flow rate with a brass .4mm nozzle. With stainless or hardened steel nozzles, it’s a struggle to get a third of that. Very much in line with your experiences. I think it has to do with heat transfer from the heater block through the nozzle and into the filament. A reason I’ve never had good luck with filaments that have fiber additives. Something I’d like to sort out some day.

thermal conductivity is a thing…

I’d almost think it would make sense to use a smaller nozzle (not nozzle opening, but z length) that doesn’t stick out as far from the heat block to reduce thermal mass of the lower thermal conductivity stainless or steel and lower the exposed area for external heat loss. Is that part of the plan? I could see the extreme case of failure being that if you put more heat in, at some point you crack (cook/char/breakdown) the filament just to get the tip hot enough to extrude a reasonably viscous enough goo to work, but then it will plug. The process window on that may be small, but others have done it, so it should be possible. Curious to see what you find.

Where’s heat lost? Guessing you have Silicone sock on the nozzle already. Maybe gasket-Maker dipped nozzle? Angle grind away some thermal mass from the steel nozzle, you only need 2 decent sides for wrench to grip ![]()

Diamond nozzle conducts heat well, diamondback on sale?

I think steel just slower to heat then a lot of plastic goes thru it and heat block made of an aluminum reports correct temperature. I am thinking of upgrading to a brass/ruby nozzle if anyone have reports and open to other ideas. I don’t want to switch nozzles for carbon but that steel nozzle at 135mm/s is slow

Brass/ruby nozzle is on my to-do list for whenever I next work on the TAZ 5, and that’s where I’ll next try to print CF filament. I have a couple of spools I want to experiment with.

The issue for me with stainless/hardened steel parts is their thermal conductivity is just too low (I think.)

Playing games to try and keep the filament at the proper extrusion temp just pain sucks.

I should get off my but and make more progress on my repeat build, but I"m just too busy with work at the moment.

That makes me wonder if the PID temperature control has a feed forward for extrusion. Presumably the amount of energy needed to move 10g of plastic from room temperature to 205C while melting it is somewhat consistent. It could vary by the type, but I bet it is withing 30% for 95% of the materials.

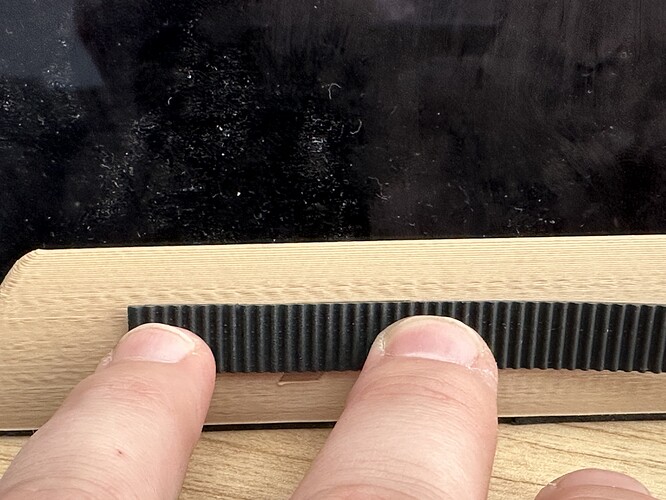

One problem I still can’t solve is these wavy patterns. These are not induced by vibration since they don’t fade. I see them if I print very slowly or very fast and spacing between these waves is always the same. Replaced all plastic parts and tried different XY belt tensions all the way to a super loose, no effect. Thinking about changing belt / pulleys to a different brand…. Distance between waves is close but does not match tooth spacing exactly

does the spacing of the waves match the circumference the balls in your linear bearing trolley?