One other “oddity” I had to set my Z stepper to 1646 steps/mm to get the correct distance movement. This seems out of wack with the others but it could be the difference between the belt movement and the T8 threaded rod movement does this seem normal? or in the realm of normalcy?

Here are my Z settings:

z:

steps_per_mm: 200.000

max_rate_mm_per_min: 1200.000

acceleration_mm_per_sec2: 80.000

max_travel_mm: 200.000

soft_limits: false

homing:

cycle: 0

positive_direction: true

mpos_mm: 200.000

feed_mm_per_min: 300.000

seek_mm_per_min: 800.000

settle_ms: 500

seek_scaler: 1.100

feed_scaler: 1.100

motor0:

limit_neg_pin: gpio.32:low

limit_pos_pin: NO_PIN

limit_all_pin: NO_PIN

hard_limits: false

pulloff_mm: 5.000

tmc_2209:

uart_num: 1

addr: 2

cs_pin: NO_PIN

r_sense_ohms: 0.110

run_amps: 0.680

hold_amps: 0.50

homing_amps: 0.5

microsteps: 8

stallguard: 0

stallguard_debug: false

toff_disable: 0

toff_stealthchop: 5

toff_coolstep: 3

run_mode: StealthChop

homing_mode: StealthChop

use_enable: false

step_pin: I2SO.10

direction_pin: I2SO.9

disable_pin: I2SO.8

This is not the case and increasing your current could lead to the steppers getting hot enough to soften the 3D printed parts.

Squareness is set by checking the diagonals and adjusting the pull-offf from your endstops. There is no accuracy at all in doing it hard against the stops as the microswitch arms would have to be at exactly the same angle as each other and they’re just not going to have that sort of tolerance.

One other thing - is there a chance you could be mixing 16T and 20T pulleys?

Well, I need to get to the point that the machine will move far enough to perform a “diagonal” squareness regimen. The pulleys and steppers came from V1 in the kit but I did not inspect the tooth count to be sure they were all the same. Yes, I’m aware that increasing the amps leads to the steppers getting hotter, In the “testing” or debugging mode making a software change from .8 to 1 is easy and quick and yields an immediate “result” I’m not running the machine long enough right now for them to get too hot. My guess is the trucks are too tight or the squareness is so far out of wack that the tension the out of square puts on the system gets compounded when the gantry moves. What is odd though is at times it was working perfectly I’d expect a “mechanical” issue to be consistent whereas a wiring issue could be intermittent. but I really appreciate the help and being able to bounce ideas off of other MPCNC users. this is what gives me hope I’ll get this monster functioning properly soon.

Thanks, I tried 200 steps/mm the z-axis barely moves when my steps /mm are that low.

Is your T8 threaded rod from the V1 store?

Please don’t be offended - I’m not trying to insult you - I mention these things which may seem obvious to eliminate assumptions on my part as much as anything else.

Speaking of - have you verified you toe heel measurements - the distance between trucks at the font and the back should be the same. Also the tubes of the X gantry shouldn’t touch the aluminium plates - both these things could result in Y not ‘tracking’ properly.

The other thing I can suggest is if you post some pictures of your setup sometimes it can highlight things that don’t look right it would be impossible to work out.

Take the thread about the esp working on usb but not on when plugged into the jackpot. I don’t know how long that would have rolled on but the first image you could see it was a 30 pin esp32 board not a 38 pin one - instant result.

Phil has a MPCNC.

No, the t8 is from somewhere else I did buy one from V! but used it on another machine build. But as part of my debugging I erased the firmware on the esp and reloaded fluidnc 3.9.1 and went back to the default v1 config.yaml and now at 200 steps/mm (default) the z axis is behaving properly. I’d still need to calibrate it but at 1646 it was going bizerk. Now I’m in the wack-a-mole stage of the debugging. I switched out the x1 stepper with the x2 stepper and that worked (once) then on the next reboot the racking came back so I know it’s not the steppers or the pulleys (both 16 tooth) or the grub screws (all tight) so I’m thinking its a firmware / software/electronic/wiring issue to flush out. I’m now getting a z-limit active warning whereas before that never appeared. So I guess I’m in the try one thing and verify if that fixes (an issue) and then see if I can repeat the process a few times to see if that fix is still working.

not offended at all. text on these threads can sometimes miss the intonation of our words. I really do appreciate the help and the suggestions I’m just trying to respond with what I tried and what is or is not working. just a back and forth.

and same don’t be offended by my type written word either. Just be glad if my words make sense and are reasonably spelled correctly.

I’ve given up on ever learning correct grammar though hence the reason why I draw pictures for a living.

Currently I’ve reinstalled the firmware and the default Config.yaml and I’m able to jog the machine at up to 3000 mm/sec x and y and z seems to be close.

next steps is to leave everything alone and shut down and reboot several times to see if the current (working) status remains after each successive reboot.

then if I have reached some semblance of stability I’ll calibrate the steps / mm again to get the machine moving the correct distance with jogs.

then I’ll square and adjust the end stops

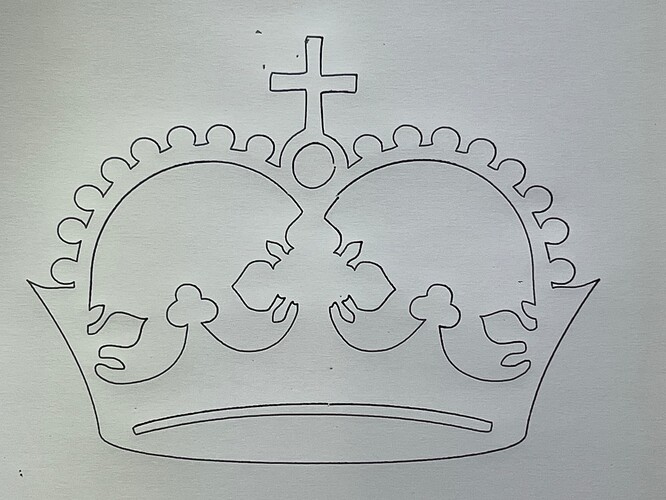

then run the crown test to see if it will run a g-code example.

(baby steps) as the saying goes.

Well, Eventually when you take two steps forward and one step back you have taken enough steps forward to make progress:

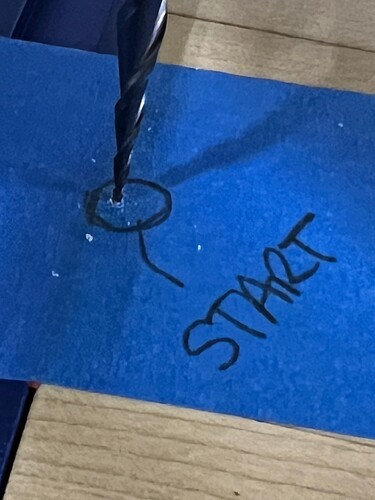

Here is the results of the first squaring run, Jogged 1200 (x+),600 (y+),1200 (x-),600 (y-)

Then I went for it and made the Crown:

Here is a video of the robot making a crown:

Next Up:

Install the spoil board

Tram the router

Install the dust collection system

Surface the spoil board

Then I need to make some stuff to sell and start making some $ so I can tell the wife:

“See I did not spend all that money and time for nothing”

Scrap all of the NEXT UP items.

Today the racking issue is back and nothing I’ve done in the past has made it go away. It’s odd. First thing in the morning I fired it up and it was working.

I tested loading a file on the SD card and running the job from the pendant. again working fine

Then this afternoon while getting ready to test it out one more time before sending an actual job…bam… the racking issue is back again.

So I re-loaded the config.yaml file (has worked in the past), not today

I re-installed the firmware only (has worked in the past), not today

I completely reinstalled everything and reloaded V1 stock config.yaml file (nope)

I back loaded fluidnc 3.8.3 thinking the latest 3.9.1 has bugs (nope)

I switched the physical tmc 2209 driver in x1 slot with the one on the x2 slot (same behavior) IE: the x1 stepper is moving much farther and faster than the x2 stepper. causing racking.

I’m about ready to throw in the towel and install the skr pro 1.2 and switch to marlin.

At least that route could confirm if it’s a hardware or wiring issue and eliminate the software and controller if the same behavior happens on the skr…however if the skr pro works flawlessly and is consistent and reliable then the issue had to be in the jackpot and/or fluidnc etc.

—or— there is the sledge hammer method which won’t “fix” anything but would be satisfying for a few brief moments.

This sure sounds like a wiring issue to me.

Yeah an intermittant bad connection would surely explain that behaviour.

You reloaded and reinstalled, but throughout this process you were not collecting and reporting the firmware’s own diagonostics.

When the machine is misbehaving, send $SS through the terminal (can be on WebUI, or via FluidTerm). Copy/paste the results here using the preformatted text tag (e.g. it shows as </> on the toolbar of the editor)

$ss

[MSG:INFO: FluidNC v3.9.1 https://github.com/bdring/FluidNC]

[MSG:INFO: Compiled with ESP32 SDK:v4.4.7-dirty]

[MSG:INFO: Local filesystem type is littlefs]

[MSG:INFO: Configuration file:config.yaml]

[MSG:INFO: Machine MPCNC]

[MSG:INFO: Board Jackpot TMC2209]

[MSG:INFO: UART1 Tx:gpio.0 Rx:gpio.4 RTS:NO_PIN Baud:115200]

[MSG:INFO: UART2 Tx:gpio.14 Rx:gpio.13 RTS:NO_PIN Baud:1000000]

[MSG:INFO: uart_channel2 created at report interval: 75]

[MSG:INFO: I2SO BCK:gpio.22 WS:gpio.17 DATA:gpio.21]

[MSG:INFO: SPI SCK:gpio.18 MOSI:gpio.23 MISO:gpio.19]

[MSG:INFO: SD Card cs_pin:gpio.5 detect:NO_PIN freq:20000000]

[MSG:INFO: Stepping:I2S_STATIC Pulse:2us Dsbl Delay:0us Dir Delay:1us Idle Delay:255ms]

[MSG:INFO: User Digital Output: 0 on Pin:gpio.26]

[MSG:INFO: User Digital Output: 1 on Pin:gpio.27]

[MSG:INFO: Axis count 3]

[MSG:INFO: Axis X (3.000,1223.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:0 CS:NO_PIN Step:I2SO.2 Dir:I2SO.1 Disable:I2SO.0 R:0.110]

[MSG:INFO: X Neg Limit gpio.25]

[MSG:INFO: Motor1]

[MSG:INFO: tmc_2209 UART1 Addr:3 CS:I2SO.14 Step:I2SO.13 Dir:I2SO.12 Disable:I2SO.15 R:0.110]

[MSG:INFO: X2 Neg Limit gpio.35]

[MSG:INFO: Axis Y (3.000,2443.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:1 CS:NO_PIN Step:I2SO.5 Dir:I2SO.4 Disable:I2SO.7 R:0.110]

[MSG:INFO: Y Neg Limit gpio.33]

[MSG:INFO: Motor1]

[MSG:INFO: tmc_2209 UART1 Addr:3 CS:I2SO.19 Step:I2SO.18 Dir:I2SO.17 Disable:I2SO.16 R:0.110]

[MSG:INFO: Y2 Neg Limit gpio.34]

[MSG:INFO: Axis Z (-100.000,200.000)]

[MSG:INFO: Motor0]

[MSG:INFO: tmc_2209 UART1 Addr:2 CS:NO_PIN Step:I2SO.10 Dir:I2SO.9 Disable:I2SO.8 R:0.110]

[MSG:INFO: Z Neg Limit gpio.32:low]

[MSG:ERR: X Axis TMC driver not detected - expected 0x21 got 0x0]

[MSG:ERR: X2 Axis TMC driver not detected - expected 0x21 got 0x0]

[MSG:ERR: Y Axis TMC driver not detected - expected 0x21 got 0x0]

[MSG:ERR: Y2 Axis TMC driver not detected - expected 0x21 got 0x0]

[MSG:ERR: Z Axis TMC driver not detected - expected 0x21 got 0x0]

[MSG:INFO: Kinematic system: Cartesian]

[MSG:INFO: STA SSID is not set]

[MSG:INFO: AP SSID FluidNC IP 192.168.0.1 mask 255.255.255.0 channel 1]

[MSG:INFO: AP started]

[MSG:INFO: WiFi on]

[MSG:INFO: Captive Portal Started]

[MSG:INFO: HTTP started on port 80]

[MSG:INFO: Telnet started on port 23]

[MSG:INFO: Flood coolant gpio.2]

[MSG:INFO: Mist coolant gpio.16]

[MSG:INFO: Probe gpio.36:low]

ok

Send Command...

Autoscroll

the bad behavior and The error messages for tmc driver must be related.

The machine still moves.

I’ve rebooted a couple of times in the past and gotten the error messages for the tmc drivers to go away before I’ll see if the bad behavior goes away when the error messages go away.

what would cause these error messages?

That’s a really broken board. It isn’t communicating with the TMC2209s.

We need to troubleshoot that.

Absent a working UART connection to the TMC2209s, the system won’t move correctly, ever.

The error shouldn’t come and go on reboots. Something is wrong, most likely ESP-32 related.

Things it might be: an ESP-32 that’s not seated correctly in the socket, or an ESP-32 that’s seen an ESD event or been in the socket wrong way round.