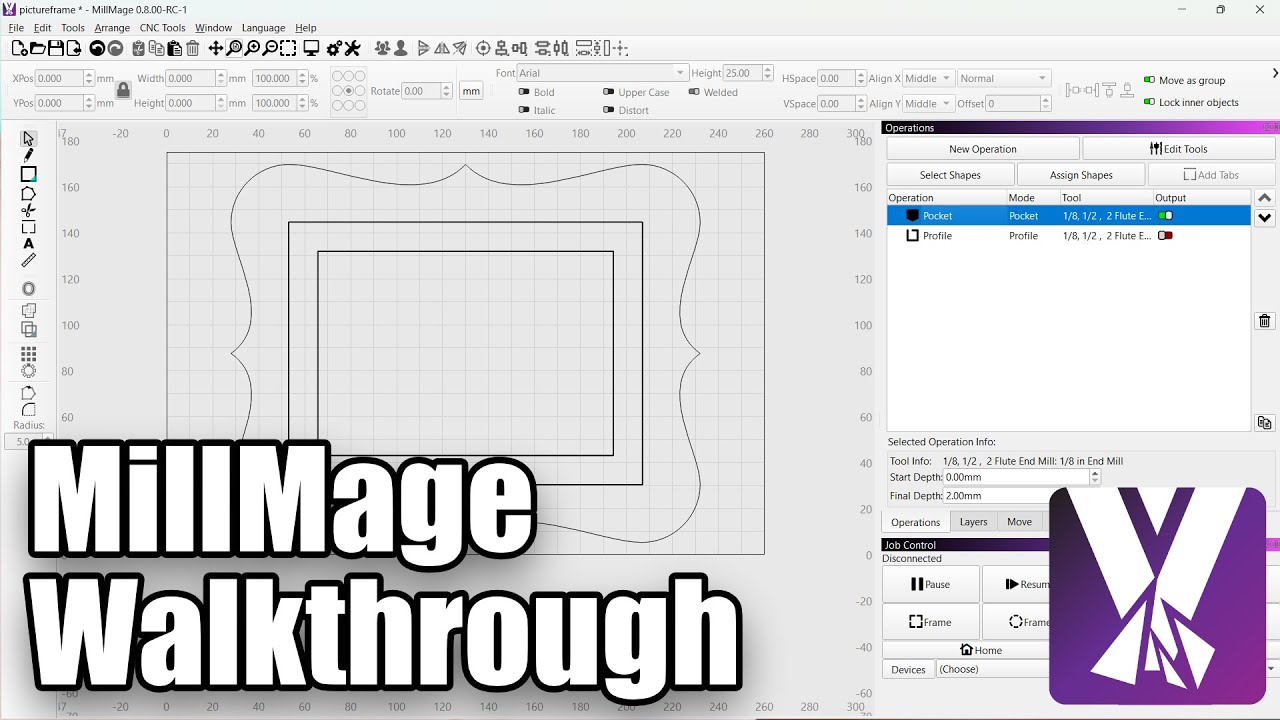

ive been using MM since RC3, here’s some of the things I’ve worked out

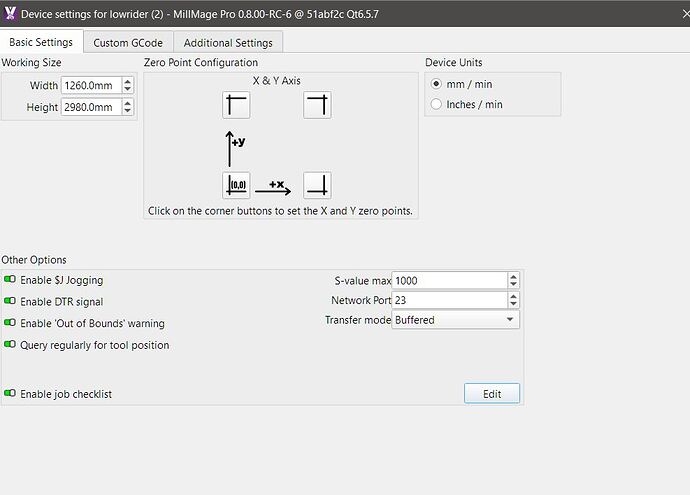

i find enable job checklist handy , you can edit it to what ever you want, it pops up, when you hit the start button saved my ass a few times.

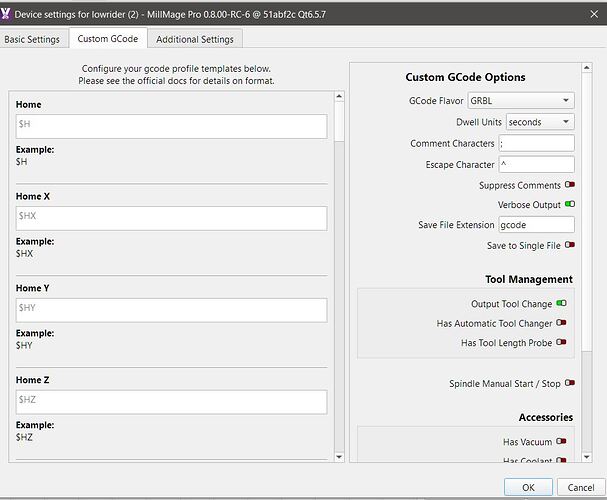

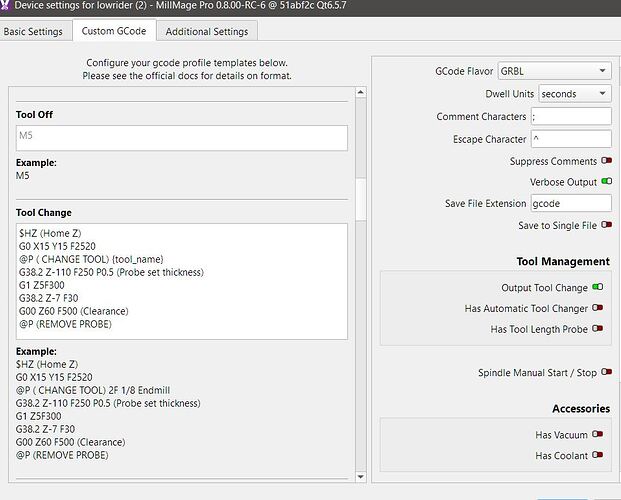

in custom G codes

on report ;

$report/interval=200

when tool change happens, pop up appears telling you which tool you have assigned to next path

(change tool) can be what ever you want ,

Remove probe - a pop up with continue or abort , not remove probe on screen.

User end script:

$HZ

G0 X600 Y300

or where ever you want it to position at end of job.

need the @ as it doesn’t understand the M0 pause command used for estlcam. Have tried few other custom codes ,they either fight each other and nothing works or it repeats its self mid job

eg i used operation end to start with instead of end script and every time it cut and object it would return to end script coordinates haha

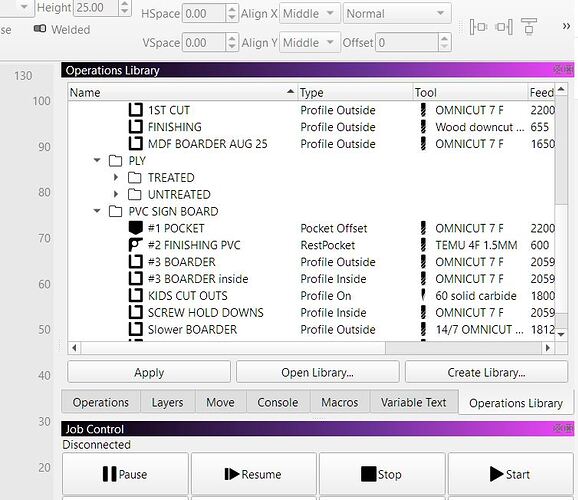

when creating new operations , if you use same material/tools regularly once operation created , right click operation and save to operation library, next time you to need run similar job go to operation library, choose your saved operation and hit apply , it saves a lot of time

the one thing which im not sure why, but if i hit stop during job Z axis dives into work piece , it never did this in fluid Nc web ui

if i hit pause Z holds position , than i can hit stop after and it holds position, have created topic in MM forum regarding this

i don’t use MM probe wizard ,always just click ignore and it reads the code set in custom Gcodes

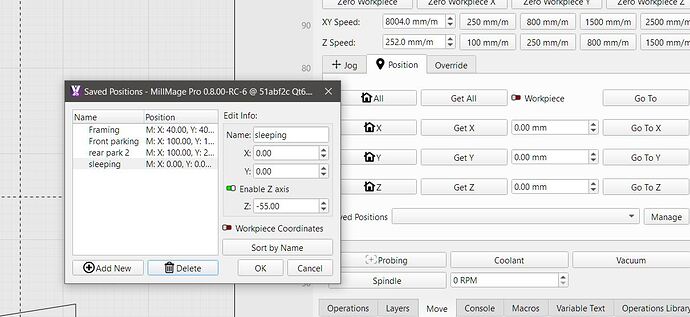

I find the saved positions really handy

once you set them up 2 clicks, and send it where you want

i have a 3m bed so takes ages if i click home or continuous jog, at the speed i have it travelling front parking is 100mm off end stops. i use my framing position all the time , don’t have manually lower z to bring it close to work piece to see where its going to frame . there is currently a bug re using center origin so don’t use that at present.

when using pocket operation it used to cut out line at your feed rate, they changed it for some reason outline now cuts at ramp or plunge feed :(, which is very daunting , they have had lots of comments about it and will be changing it back to your federate.

when setting rest pocket operation, make sure you check clearing tool diameter box, doesn’t always match what your pocket tool is and in preview areas are uncut.