I tried my workaround but I broke Millmage in the process. I commented on your post on the Lightburn forum with those details.

Hopefully you get some traction. My post got completely ignored.

? Broke millmage what happened

I added some fancy gcode for a tool change and it did not like that. It let me save but never added it to the gcode and now that section doesn’t show up at all where you set the custom gcode. I was able to toggle the gcode flavor and get it back.

I’m frustrated with MillMage. I quit with it for now.

Custom gcode is limited and fragile. @Jonathjon posted on the forum, which I replied to twice, and still no response. Perhaps this forum has raised my expectations too high. Maybe the forum isn’t the appropriate place for issues?

I don’t know where else there is for feedback.

I came to an immediate stop. I was going to use it for the project i have. I started by loading my last project in and comparing. It worked for 90% but it had parts missing.

I then found out v carve was missing. (so i have to say i use this the most!). I then found (relief) carving is missing also. That is my next project! I want to do a very nice mirror frame via stl, so i am done for now. I will continue with estlcam.

I told them from the very beginning that this was the main selling point. Now it seems they have abandoned this thread as well… ![]()

I am pretty sure they have their hands full for a bit, another RC just came out. I would venture a guess that there are a ton of small bugs that take priority over new features. I am sure the home forum takes priority over us as well.

Yea, I’m sure they’re busy. I did post on their forum. I see they’re also putting out Lightburn 2.0 RCs at the same time. I guess I should be more patient.

Their forum seems challenging since there are people with all different CNCs and all different levels of knowledge. There have been some pretty obscure posts too. Taking all the gcode variants and then throw in the control side and they’ve got their hands full. I guess it’s similar here, we’ve just got a bit more focus.

From my perspective, the two things needed prior to official release are V carving and improve/fix custom gcode.

I think 3d carving can wait. The reason I think V carving is necessary is because you can use the design tools (especially text) to create things that you can’t cut since it can’t do dynamic Z with a v bit to get into the corners.

I suppose the custom gcode issues are partially me trying to do extra things but it should at least be less fragile. I was fiddling with my own post processor using placeholders in custom gcode to get what I wanted. But, between a work trip and vacation, I won’t be home much this month to mess with any of it.

The last thing I was messing with was some gcode where it translates the RPM set in CAM into the dial setting on my Kobalt. So, if the RPM specified for the endmill is 12000, an M0 message tells me to set the dial to 1.5.

Honestly, these are very difficult geometry problems to solve and there are a lot more weird corner cases than you’d think. Testing, finding, and fixing those corner cases adds a ton of work. So I’m not surprised at all that it takes more time. I’m honestly impressed by developers like Christian or Stewart that can make these products solve those problems by themselves.

With LightBurn, I found I was limited by what the Custom GCode could do, so resorted to having my post-processor (in-flight proxy, actually) key off of feed speeds to modify or insert code. For normal ‘laser stuff’ I use speeds that end in 0. For pen plotter stuff I use speeds that end in 1 and insert up/down commands as needed… and then insert tool change commands when the speeds change between ending in 0 or 1. Since it’s in mm/min, the last digit isn’t really significant at all, so free to use for this.

The LaserBurn forum (rather than the MillMage forum) is certainly this way. People are all over the map; and there are so many variants of cheap hardware out there… much of the hardware is more or less the same, but it’s so cheap that the crowd it attracts has wildly varying clue-factors.

For what it’s worth @LightBurn was quick to accommodate modifying LightBurn to increase the maximum laser machine work area jog command inputs from 3 x 3 metres, to 10 x 10 metres to accommodate my laser cutter. It was a simple change, but he could have ignored it. Instead he included it in a release a day or two later.

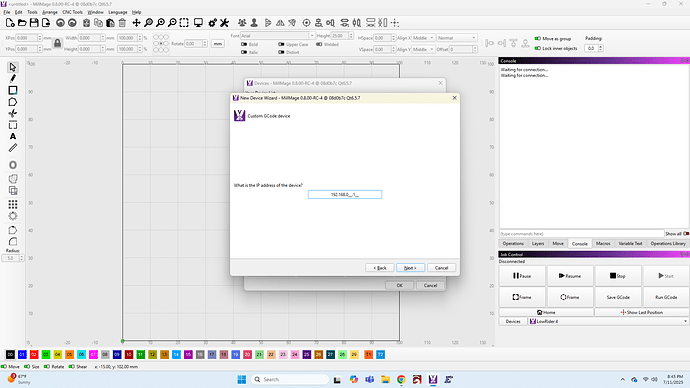

I am one of those individuals. I have been eagerly awaiting the release of MillMage since I am already using LightBurn for my Laser. Since it doesn’t require learning yet another new piece of software (so similar to LightBurn). I am not the brightest, but have been able to figure out the software side of things up till now… I know it is supposed to be as simple as plugging in your Jackpot’s IP Address, but no matter what I have tried, I cannot figure out why it will not connect. All I am getting is “Waiting for connection…”. If anyone has any ideas, please shoot!

Is your computer on the same WIFI connection as your Jackpot? Or are you using the Jackpot in AP Mode?

I have tried it with computer on Jackpots wifi connection, but to no avail. Not familiar with “AP Mode” sorry.

AP Mode is using the WIFI that the jackpot puts out. STA Mode is having the Jackpot hooked to your home WIFI. I have only tried millmage over the STA Mode. I cant speak to how it will work over AP Mode.

STA sounds like the mode I am looking for. I was literally just able to connect via AP mode after re-reading some old posts and trying again after changing to my laptop and getting a lot closer to the machine. This is already a huge improvement after all the weeks frustration!!! I guess I will look into the process of hooking the Jackpot to my home WIFI and STA mode so I can use my desktop which is in the same room, but not as close. Edit: Found it here: (Jackpot STA mode is easier to recommend now)

Thanks for your help @Jonathjon !!!

your IP is wrong , i had same thing happen , you need to keep re typing it till the ( _ _ ) go away once i got rid of then it connect straight away i didnt change any settings in fluid nc

i think i deleted the 68 than typed .0.1

192.1.0.1

than went back and put the 68 back in

was only way mine would connect

Thanks @Terry_O_Sullivan ! I ended up connecting to the jackpot via cable, updating and assigning my wifi to it. Now I am connected via STA through home wifi connection. Running GREAT!

http://jscut.org/ vi used this with inkscape and a home-made laser for a long time