My printer is working fine! Why are you trying to make me build a new one!?

Thanks guys. Now I just want to tune it a little and add some accessories.

What are the pin identifiers in Marlin for the 3 fan outputs?

I have added a fan to FAN2 and want to be able to control it with the GCODE but I am not sure how to do so. I would assume using M106, but I don’t know how to designate which fan.

Fan0= the print fan

Fan1= the hemara cooling fan, comes on at 50C

Fan2 is open, It will end up being a M106 M107 command I believe. Fan 2 is PE6, so M106 PE6 S255? Just a guess.

Hmmm, I tried this one before and it didn’t work. I will try again. Does the Marlin firmware tell me what the pin #s are if I were to look into the firmware?

It is definitely PE6, All mine are running and I can’t test anything.

Try

M106 PPE6 S255

Or M106 P2 S255

P2 did the trick.

Ive learned:

M106 P0 - Extruder Fan

M106 P2 - FAN2 (for me is PSU fan)

and I have not figured out what turns on the part cooling fan.

P1 did nothing

Heat it up past 170C and it should come on automatically.

Oh yes it does do that. I was just curious if I could toggle it manually by GCODE. For absolutely no reason at all though, so it’s not a problem.

Never tried. I am a little surprised you can toggle the extruder fan though. The good thing is this board has so many other pins you can use, including the big bed mosfet as well.

What print speeds are you pushing this puppy to?

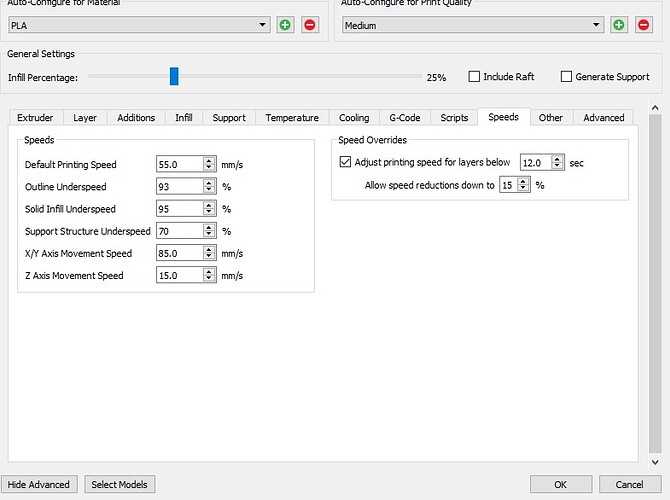

My extruder with a 0.5mm and thick layers nozzle maxes out at 12mm^3/s/s, which equals 55mm/s for me. Teaching Tech has a great calibration site. That is how I found my max flow is about 12mm^3/s/s. If you are using a smaller nozzle you can go a bit faster, but I highly recommend pushing more plastic instead of moving faster. 0.5-0.6mm nozzle is great.

I print flawless LR3 cores in ~9 hours, some people are quoting days, so I feel good about that.

Okay who here wants to help me with tuning my printer??

I noticed in my prints that the retraction/priming wasnt very good. There is a bit of stringing (not terrible) and also the bit of extrusion right after a retraction doesn’t have any filament extruding. I can see gaps where the print head is changing direction really quickly or where it has just started again after a retraction.

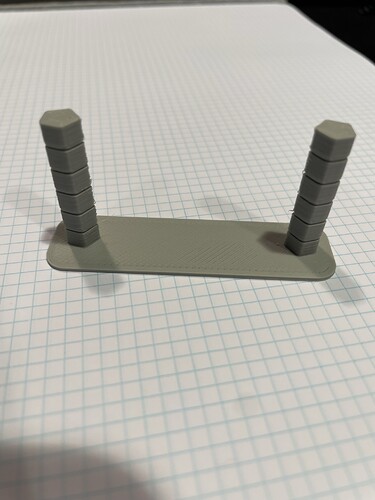

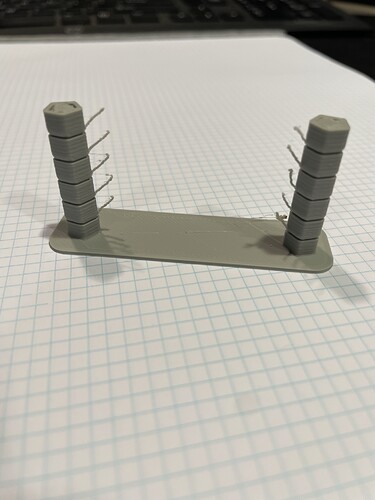

So just now I thought it would be good to do a retraction test print. Here is the result…

This is supposed to be the tower test piece that has 4 pointy towers in each corner. I stopped it about half way through when I could obviously tell it was barely printing anything. Clearly the rapid movements from tower to tower were not good for the current state of my printer.

Where do I begin? I have started playing with my retraction distance and speed.

Teaching tech has the best setup and calibration walk through ever.

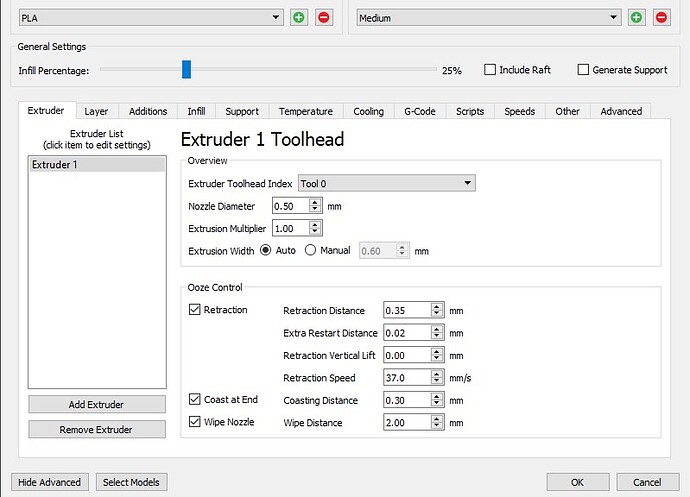

The retraction stuff depends on your extruder. I have the hemera with a 0.5 nozzle set at

Okay interesting. I have the Hemera as well with 0.4 nozzle. I do not see much difference in our settings other than I have my retraction distance at 1mm. Ill bring it down to 0.5mm and see if that changes anything.

There’s a lot of settings that interact in subtle ways. If you haven’t worked through it, I strongly suggest going through the Teaching Tech calibration site - https://teachingtechyt.github.io/calibration.html in order. It doesn’t take that long (and you’ve already clearly got some elements sorted out) and the sequence helps to eliminate “looping back” and having to re-tune something again after adjusting an underlying/prerequisite setting.

There’s a big difference between retraction for a direct-drive versus a bowden set up. My direct-drive Titan Aero extruder only needs around .3 mm retraction. I’m also using linear advance, which interacts with retraction.

yeah 1mm is way too much 0.5 is still pretty big. Use the teaching tech retraction test.

Okay so I did the teaching tech calibration. Here are my results using 1mm at the bottom all the way to 0.5mm at the top at 0.1mm change per level. 40mm/s retraction and prime speed. Looks pretty good.

Then I took the 0.5mm retraction distance and 40mm/s speed and put that into Cura to try it in my own slicer (I use Cura, would anyone recommend an alternative?). I did not get the same result as the teaching tech generated gcode. Clearly other factors involved.

Now I will try linear advance I guess. Cura doesn’t have a linear advance feature built in, but there is a plugin for it that I added. I assume it’s an effective plugin. I will give it a try.

Both of them look like you are not getting the changes you need. Looks like it is printing with the same settings all the way through.