Well then…

I originally had a foam square sandwiched under my bed to help keep it warm but doing that made it so that there was no rigid way to bolt it down. I could tighten each corner of the bed separately and squish the foam more and more in each corner. So there was no way to guarantee that each corner was at the same height.

SO, I put these spacers on each M3 bolt that holds the bed down. This should guarantee that each corner is at the same height. Atleast I thought.

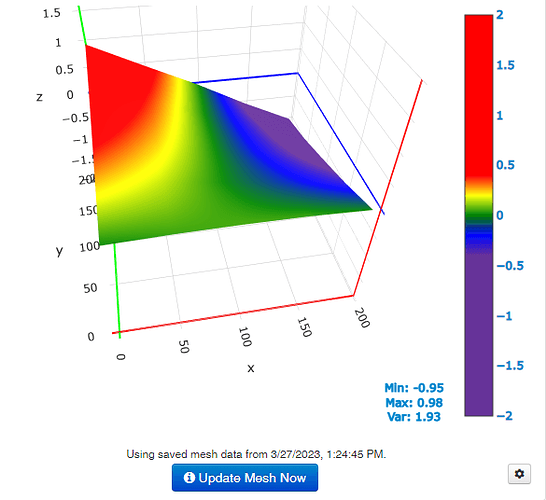

I also did the test with the bed at 70C.

The front corners seem perfect. But the back corners are definitely bad.

Maybe it is the umbilical cord? Think it could push and pull on the print head? Hard to believe it would be pushing and pulling that much.