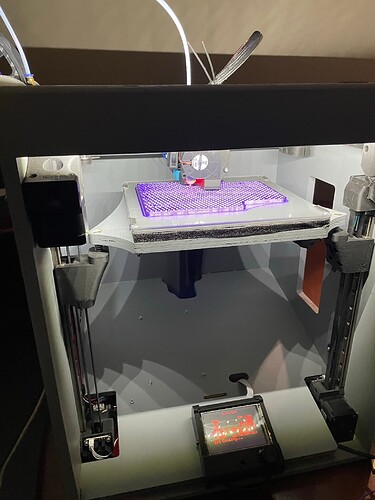

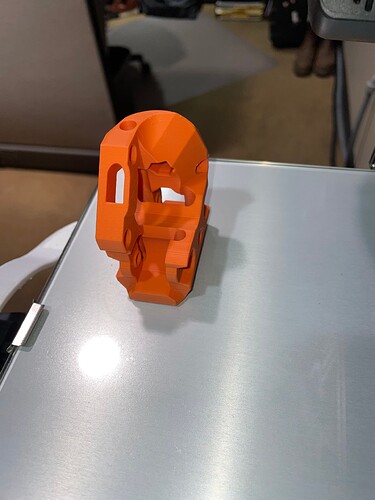

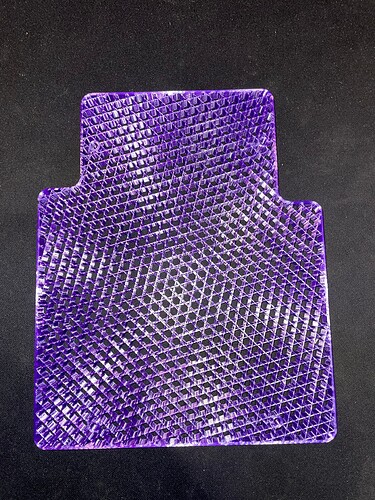

Somehow, some way, I accidently printed most of the parts for the V4 Repeat. And aluminum extrusions just randomly showed up at my doorstep the other day, not sure how that happened…

Guess i’ll just have to go ahead and get started on upgrading my printer soon…