Recv: Z2-Z1=0.39 Z3-Z2=0.11 Z3-Z1=0.28

Recv: G34 Iteration: 3

Recv: Z2-Z1=0.22 Z3-Z2=0.17 Z3-Z1=0.05

Recv: G34 Iteration: 4

Recv: Z2-Z1=0.08 Z3-Z2=0.07 Z3-Z1=0.01

Recv: G34 Iteration: 5

Recv: Z2-Z1=0.07 Z3-Z2=0.09 Z3-Z1=0.02

Recv: G34 Iteration: 6

Recv: Z2-Z1=0.14 Z3-Z2=0.10 Z3-Z1=0.04

Recv: Decreasing Accuracy Detected.

Recv: Decreasing Accuracy Detected.

Recv: G34 Iteration: 7

Recv: Z2-Z1=0.21 Z3-Z2=0.09 Z3-Z1=0.30

Recv: Decreasing Accuracy Detected.

Recv: G34 Iteration: 8

Recv: Z2-Z1=0.47 Z3-Z2=0.12 Z3-Z1=0.59

Recv: Decreasing Accuracy Detected.

Recv: Did 8 of 8

Recv: Accuracy: 0.59

Recv: ok

I still haven’t quite figured out why my bed leveling is doing this. I wasn’t able to copy far enough to see iteration 1 and 2, but you can clearly see the accuracy is getting better up until iteration 5 where it starts going the other way. Very strange behavior. I have all 3 Z Axis belts tensioned snug but not over tightened. I have the PTFE tube running all the way out and mounted to the wall of the machine so the filament isn’t pulling on the extruder at all. Regardless, you can see the accuracy is getting better and then it decides to start getting worse. This happens consistently every time. Would it be worth replacing the BL Touch and ruling that out?

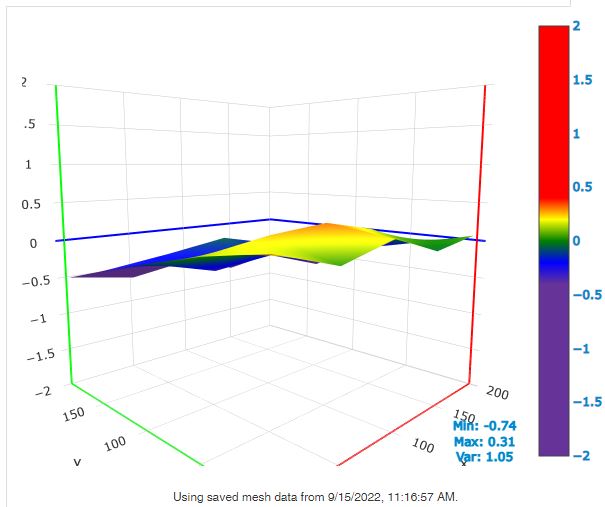

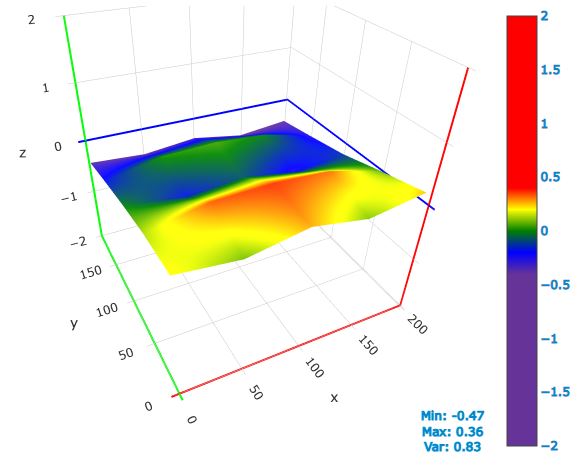

I should note that the bed itself is quite out of plane (i.e not flat). See the results of the mesh leveling below. I ran it twice 24hrs apart. It appears to be much higher in the front than it is in the back.

Now, I know this is not ideal by any means. BUT, the Auto Z Leveling I am having problems with should not be effected by this, right? Auto Z Leveling finds a level plane between ONLY 3 points and should not matter what the rest of the bed looks like. It will still level 3 points of the bed.