Nice ![]()

Clean compile now! Im using this one, config with with the “upload robin nano firmware” description.

Just a quick note. I took a detour on the alpha release of version 1.4 to redesign µCNC extension modules system, before trying to come up with a new module for bltouch.

This is just some technical stuff mambojambo but what I did was a C# flavored implementation of events, delegates and listeners in plain C. This allows me to create hooks along the core code and attach multiple modules to those events to do tasks.

Translating into simple language…I’m doing stuff. Bltouch module for testing soon.

This shows the switches are wires as Normally Closed (NC). This is the preference for safety/limit switches on CNC equipment because the sensor is read as “triggered” (and the machine stops) if a wire gets cut for some reason.

3D printers often use Normally Open (NO) switches, where the signal is only present when the button is pushed. By default, Marlin firmware only pays attention to the switches during homing, so the extra safety feature of NC switches has no benefit.

@bastardazzo just to let you know that the initial module for bltouch and the initial version of delta have been integrated in the master branch that has all new stuff for new release version 1.4.

BLtouch took me a bit more then I expected since I was forced to modify my SERVO pin types to work with a range between 0.5ms and 2.5ms.

Again I don’t have a delta printer or a BLTouch probe to test it properly so you are more then welcome to be the guinea pig.

From now on you can download and upload the firmware from the master branch.

Great! Im excited to ocntinue working on my side of the project  thanks again for putting all this effort in!

thanks again for putting all this effort in!

Unfortuantely I returned my BLTouch so i currently dont have it, but as we already talked about its a good contender for the eventual probe the machine will need, which will be sooner that later i suspect. I just want to give a shot at the piezo/nozzle probe because it would make it so much more streamlined!

Anyways, ill let you know if I get another BLTouch!

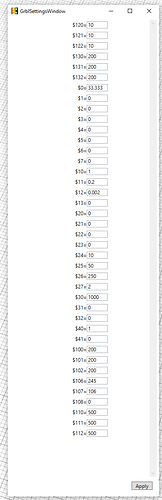

I worked on trying to find out $106 and $107 values for the Q5, but i didnt find an answer on google…

From a cad model I’ve been working on I measured the $107, which seems to be 109.3mm.

This comes from a compounding of various measurements as im trying to recreate parts of the printer to in CAD, It should be correct though!

And the $106, arm length, says its 210 on their website but I triple-measured 214.5, centre to centre as mentioned

Ill try to turn it on tomorrow morning for the first time since RAMPS!

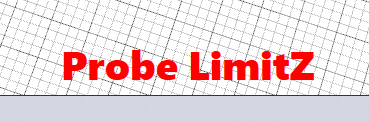

Sidenote: ive noticed that the LimitZ appears as Probe LimitZ when its pressed the first time after booting and/or after pressing either the X or Y limit switches… Probe LimitZ should be impossible since I dont have a probe connected lol

After the first time in each case it continues to appear as LimitZ, normal…

Maybe both limit z and probe are “wired” on the same Pin.

I’ll check that out as soon as I can and I’ll let you know.

EDIT: About that $107 parameter you can check your mesurments by mesuring the distance between 2 towers (taken from the middle of each tower joint). Divide that distance by 2 and then divide Again by cos(30º). This should give you the radius of the outter circle tha passes through the tower joints.subtract the radius of the effect or and you have the vale to put on that parameter.

This is based on This relation

EDIT2:

Reading your post and looking at the config file for your board Z limit is configured to Z- on your board and Probe to Z+. Check that your Z limit switch is connected to Z- on your board.

If Probe alarm is still active that might be caused by parasitic capacitances that make the MCU read 1 on that pin. For now since you don’t have a probe you can do the following. You can activate the internal pullup resistor by adding #define PROBE_PULLUP inside your boardmap_ramps14.h file. Then you just need to invert the probe pin setting by sending configuration $6=1.

Later when you install the probe that might this setting might be changed to fit your probe.

Tried this method but I got an odd number from it… measured manually off of the machine, 106 is the correct $107 in my case. This made me find an error in my cad model! thankfully better now than later

Turned on the machine and send a G0Z1…nothing moved ![]()

When I turn on the machine I hear the motors lock in place with almost like a single click noise and then no more feedback. The motors are super stiff, really need to force them with my hand to move them manually.

I just noticed my stepper driver heatsinks are super hot to the touch when the psu is on.

I believe all my connection are right

The command goes through and then this green bar goes up in OpenCNCPilot, thats all… ![]()

Did you unlocked the cnc before the G0? (unlock command button or send $X)

Your drivers heat sinks Will get a bit warm Yes. Specially if they are stalled. After they power up they should be locked and the must be Hard to move by hand since they are powered up. If you feel they are getting too Hot reduce the current a bit.

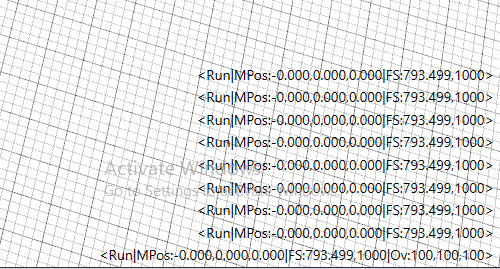

EDIT :post your settings here too.

EDIT2: If you turn the debug message option does it pop any thing out of the ordinary?

I hadnt! Ill try that now!

Ill also plug the fan in to help move the heat

GRBL Setting you mean?

Try sending a manual command $X

That’s the unlock command. Since you activated homing and hard limits the initial state of µCNC is alarm mode. This will only go away if all systems are OK and you do either a homing or explicit unlock command. This is the same as Grbl.

That’s odd when you turn the debug mode are messages being exchanged?

Yes, theres a constant flow of positions

Is your Arduino board running at 16MHz or 20Mhz can you check the xtal value please?

The crystal oscillator has 16.000 written on it

Ok. It’s an issue with µCNC. I’ll get on it an tell you something as soon as I get the problem fixed.

Could it be that my drivers are burnt? I don’t think they are but it could be a possibility right?

You had mentioned that moving the arms really quickly could damage the drivers, is there a way I can check or do you reckon its not that?

nop it’s the µCNC. I’ve just checked. The strange thing is the behaviour of it. Never the less I’ll investigate it.