I’m not having any build plate adhesion problems, but that is an interesting thing about the TAZ.

In the pictures above, you can see that it’s got a glass bed, and I use a specific, really crappy hair spray as an adhesion agent.

Most parts adhere really well, including the black inland filament stuff that is giving me problems. They also release reasonably well when the bed cools back down (I heat to 60C for PLA).

Worst case, I loosen the mounting ears and put a build plate in the upright freezer in the garage for 5 minutes, and all the parts are off it.

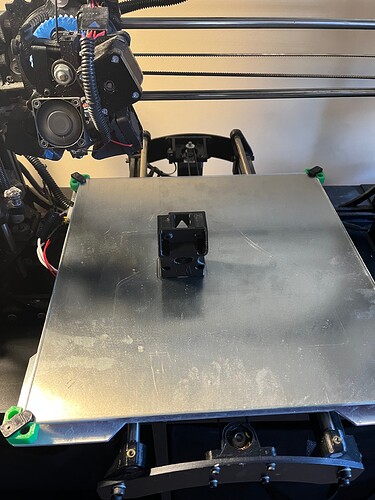

A careful look reveals that isn’t a stock Taz 5 plate.

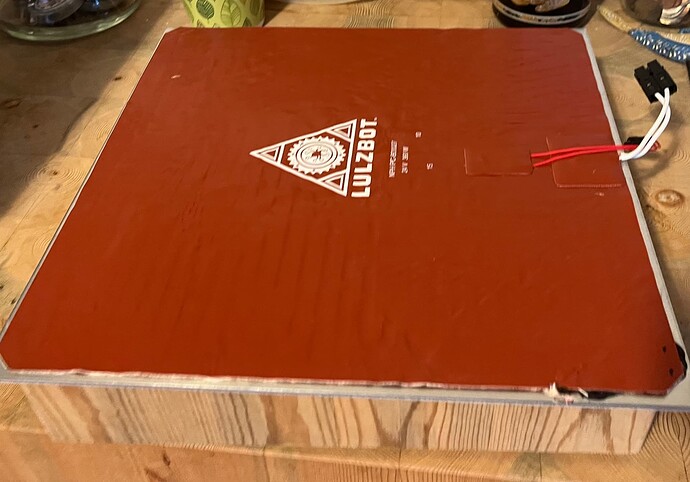

I bought the printer used with really low run time from an older gentleman who had messed up the factory PEI surface, and was improvising his own. The factory Lulzbot Taz5 bonds a silicone heater to a borosilicate glass bed and then bonds PEI to the top of the glass.

What the fellow I bought it from had been doing is to cut down picture frame glass (!!), bond the silicone heater to that, and then mount it in the stock mounting tabs.

The Taz has a horrible (in my opinion) mounting arrangement with four mounting tabs at the corners.

The previous owner had been regularly breaking his improvised build plates and was simply rotating three different silicone heaters and peeling off/re-mounting silicone heaters as he broke them. He was completely frustrated. He also had a collection of other interesting habits for ‘maintaining’ the extruder assembly and I suspect had mis-located the y axis (bed assembly) at some point. I lose about 20mm of print area on this printer as a result, but haven’t had it apart yet to fix that.

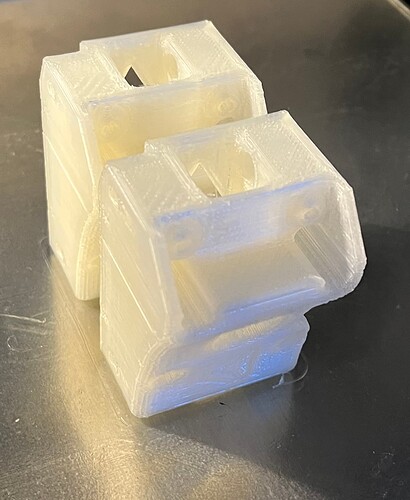

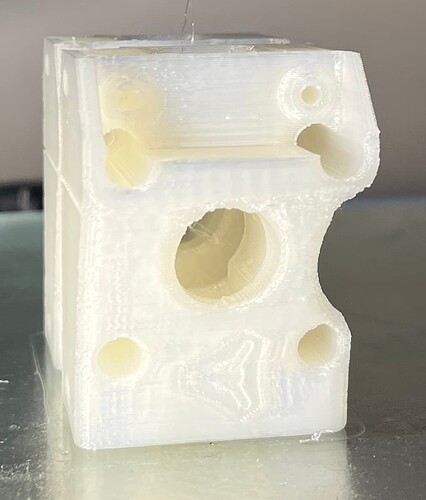

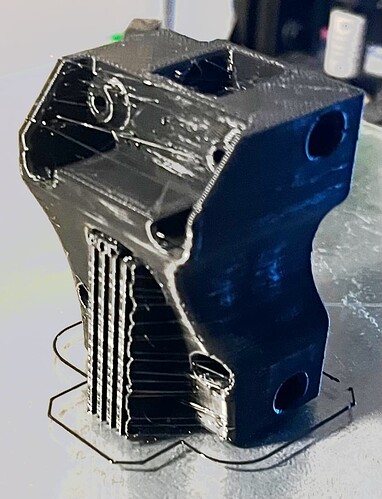

At any rate, when I bought it , as a temporary measure I took a 12 inch square, 3/16" aluminum sheet and bonded one of those silicone heaters to one side. I then put one of the previous owners’ spare cut glass sheets on top of that. I printed up some modified corner mounting tabs slightly enlarged to accommodate the 12x12 bed, and slightly thicker as the build plate is a bit thicker than stock.

I had assumed I’d break this in short order, and started working on a better build plate.

I’ve yet to have any problems with my ‘hack’ of a build plate.

In the meantime, I have another version, also based on a 3/16" aluminum sheet, but with an adhesive magnetic sheet and then a removable spring steel pei sheet on top of that. This is again slightly thicker, and I’ve been waiting for over a year to switch to it. No idea if it would be better- my first hack is working and since it isn’t broken I haven’t ‘fixed’ it.

I mention this in part also because I’ve been debating using that same spring steel build plate as the build plate for my repeat build (would need to add some mounting holes for the kinematic mount points.)

I still have one 24V silicone heater pad available, so maybe I’ll build up a fresh one for the repeat. Is anyone else doing similar? That would define my build if I went that route, for a 12"x12’ build plate size.