Hello Ryan and the greater V1 community,

I, like many others, am jumping on the LR4 train… I built a 24” x 24” MPCNC back in 2020 with some of the free time I had. I always had my eye on the full sheet lowrider but I’ve been busy. Somehow the LR4 release caught me at the right time. I’m still busy as ever, but I do have a little extra time around the holidays. So… the gantry was assembled over Thanksgiving break.

I got a bootstrapped table laid out a week or so later. I knew it’d be on the ground for a few weeks so I laid some plastic down as a vapor barrier and lifted the spoilboard up of the ground on slats. All to prevent it from picking up too much moisture. I did a rough wiring job down on the floor and got it moving. Next I squared things up before cutting my strut plates.

My strut plates cut fine but the next test I ran, the Z height dropped on me. Z dropped to the point where the collet nut was rubbing on the workpiece. Following this failure I increased the Z axis run amps from .8 to .9 and I increased the Z-axis hold amps from .7 to .8. I have not had any issues with the Z plunging since making this change.

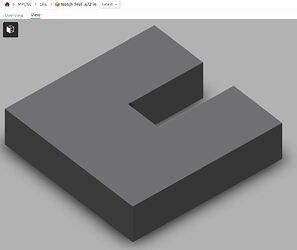

Before cutting my table I made a notch test to make sure that a .472” wide cut will indeed slot into another piece of plywood. This may be haunting me now. The samples did indeed slot together but were quite tight, needing a mallet. Slots measured about .455” which I attributed to some fuzz. Outside dims of the piece were about .011” oversized.

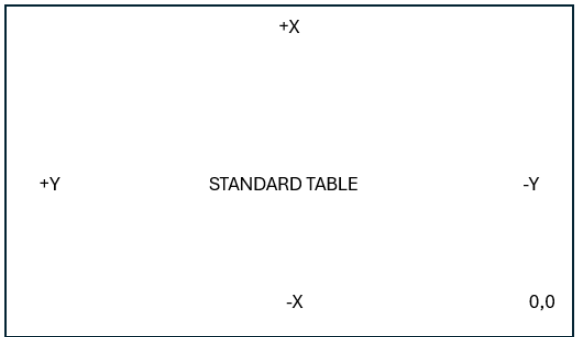

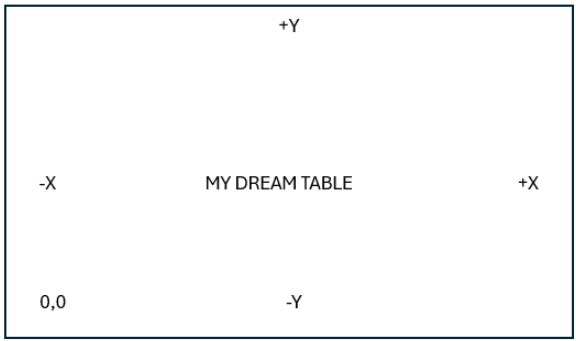

Now I’m in the process of cutting and assembling my torsen table. I took Doug’s file and modified it to closely match the official table. I changed Doug’s to 1/2 in ply, made it 4 in tall, I increased the number of X and Y members to 10 and 5 respectively. I also adjusted some internal table dimensions.

I added a hole in the X-rib for a pivot. I plan on building a cart that the table can pivot onto. Then it can be moved out of the way if I have other large projects in the shop. Inspired by “SATXDIY Sean White” on YouTube.

I am looking forward to getting the table built. I need to get this thing and up off the floor and get some dust collection on it. In a hurry, last night I had some time while the LR4 was cutting out the final X-ribs and I tried to start the table assembly. Well, my notches were pretty tight and now I need to cut 3 more X-ribs. I will take my time, chisel out some more clearance, and use a board over top of the rib to do my mallet beating on…

My plan for electrical is to mount a 6 gang box with,

- e-stop

- 1 main power switch

- 1 manual router switch in series with the SSR

- 2 SSR switched 120v outlets for router and shop vac

- 2 120v outlets that are switched by the main power switch for the 24V power supply, etc

- 2 120V constant outlets for computer/tablet

Depending on the room in the box I may add buttons for feed hold, start, and probe. I’ll probably run a length of CAT-5 from the box to the jackpot regardless. From what I read the physical buttons and the FluidNC Jog dial pendant are mutually exclusive. At this point I’m giving the pendant more time to solidify their implementation. (which is code for “I’ll probably start on it next week”)

With any luck I’ll have the table built and have the thing running again this weekend.

Bill