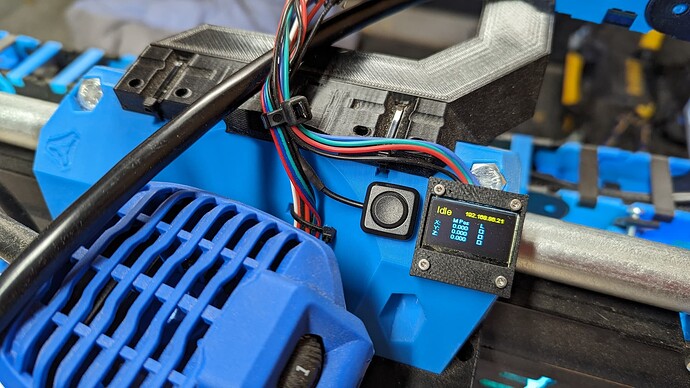

1.5" RGB OLED?

Ok I need some info for this…

This is what I bought:

https://www.amazon.com/dp/B0B7RPCZ4Z?psc=1&ref=ppx_yo2ov_dt_b_product_details

This is the reference to displays in the fluidnc docs:

http://wiki.fluidnc.com/en/config/displays

I was clicking around those docs, saw this, and had to at least try it out. My use case: the Jackpot is on my home network, it’s helpful to confirm its local IP in order to connect. Really easy to implement, assuming you have a couple gpio pins available.

I am probably mount it on the Core once I have a case for it.

i just so happen to have a few of those screens. And yes just to be able to verify IP and see position its very nice. I have mine set up static IP but every once in a while i have a brain fart and forget LOL

So what’s the thought process for this? Is it to have a screen for positioning when starting a job, fun analytical thing while cutting? (ip status I get), no hate just curious what the intended purpose is

Nerding out and adding complexity, mostly. (I know, Ryan, sorry.)

I’m also hoping that a quick glance at the status on the screen when doing tool changes will remind me to probe, since I’m a bonehead and forget sometimes (despite a change in LED colors and patterns ![]() ) which leads to failed cuts.

) which leads to failed cuts.

Love it, I’d be curious about mounting it to 0,0 on the table just to watch it change as it moves around. But that again add more complexity to it

Build it into your CAM, manual probing is always going to lead to issues.

I do, but sometimes I forget to attach the probe before hitting resume…

Will it run pornhu Doom?

Everything runs doom. ![]()

Obligatory:

Very useful use case. Just that feature is worth it (more than worth it, they only cost a few dollars from aliexpress).

I have a bunch of these and I use them in several projects. You can even use them with ESPHome. They do suffer from screen burn in (really more like burn out) after a few years (at least the oled black and white ones do). Just knowing that it connected to the wifi is a good enough signal thing to add.

I also always add some moving character. I found an extended character set that has all 6 die faces, so my thermostat climbs through those 6 faces once per second. I can tell that the screen is updating and the code is running, which is nice when you wrote it.

That’s slick! I wonder if there’s a way to do that with the Jackpot. Guessing that’d be deep in FluidNC though.

It would definitely require editing code. I’m sure there is a section where the drawing calls are made. They probably use the adafruit library or something similar for the ssd1306. The calls are nice and standard like, addText("hello", 0,128);. You would have to edit the string that gets created and update it to have your special character (and you can start with a single digit number).

The slightly harder part is making sure the drawing for the screen is called from somewhere important and frequent, so you can tell it is running.

But honestly, if you aren’t actively developing it, you should just assume it is cycling and your display is fine. It’s mostly useful when you are testing new code.

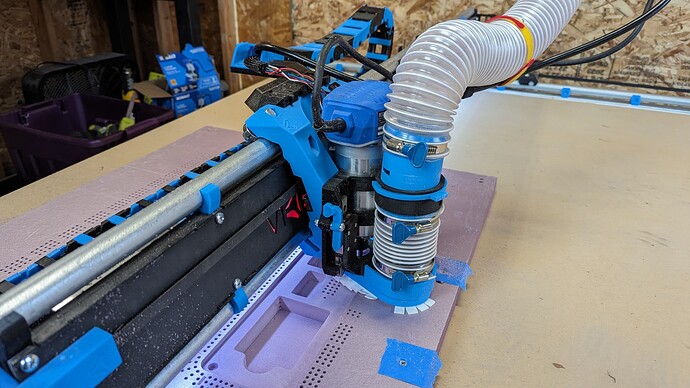

Finally done with my extra core mods!

Probably another day or two until it moves again, but getting close!

Three wiring tips:

Always twist power and ground

Always twist power and ground

Always twist power and ground

The gantry is finally all buttoned up for the time being. Time to play in foam to test all sorts of stuff for my first “real” project!

Way to go!

Very cool looking. What are you triggering with the button on the core?

I’d love to install one to unpause, rather than having to get back to the control screen. I’d also like one to execute a probe, especially if I could see the z value on the screen. Might be useful to get an idea of how much to take off in a leveling/planing process.

Resume, for exactly the same reason - not having to trigger it from a tablet/laptop, which is awkward when probing. All my probing is done via the start/toolchange scripts in Estlcam, so I don’t really feel the need for another button.

Also, I had to move the screen to be mounted on the rear strut. I guess the wiring was too long, I couldn’t get the screen to work consistently on the core. The good news is that it does what I need it to do. It also displays a progress bar while a job is running, so that’s pretty sweet too.