Had the same problem. I ended up soldering (slightly thicker) wires to the switches, and everything works brilliantly now.

Ignoring the stuff I don’t know a lot about for a bit, and back to the overthinking of my own kind.

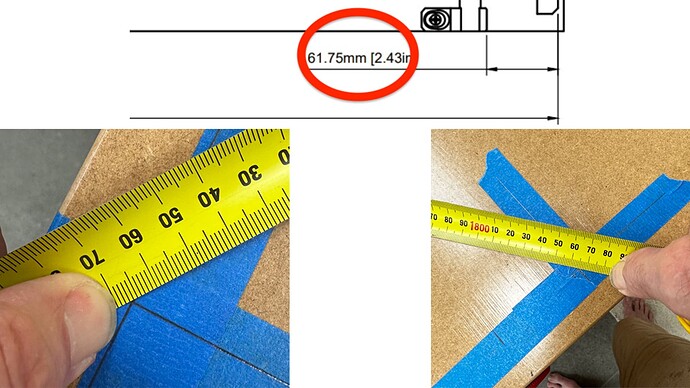

I am keen to make sure that the “fenders” will work, and I always think that getting things in accordance with the plan and right in the first place will help, so I measured twice, then had a cup of coffee.

Then I measured twice again and checked the plan.

What manner of evil is it that thinks that .75mm is an acceptable dimension to build things to? I’m a “thickness of a fat sharpie” kind of guy so this makes my head spin, but I’ll play your silly game.

So I measured twice and laid it all out on tape. Then checked the diagonal which seemed to be well within my pencil line tolerance.

The reason for this is not quite a joke - the closer I can keep that “front” line and therefore the Y end stops square with the rail, the more chance I have of keeping things that way.

So I guess I’ll measure twice more and bolt everything in place.

And before anyone comments on the “safety feet”, that’s just part of our traditional national dress.

Have you fastened down your front belt holders yet?

perhaps after lunch…

I have a new one I made yesterday…adjustable. I can give it to you tomorrow. Two print real quick.

I’ll hold off for that then! It will save me reprinting the “gasket” shim in something other than orange!

Out of curiosity, why are the back “dovetails” only dovetailed on one side?

There are no dovetails on the back ones, just a slot.

I made a note, I will post them to printables, If I forget remind me please.

Which of your many lists is that note on? ![]()

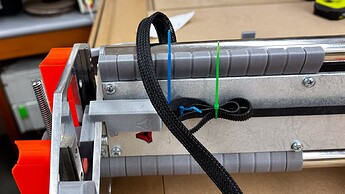

When the boss says “I’ll have a new part for you tomorrow” a sensible fellow might have taken the rest of the day off, but I just saw it as an opportunity to break out some clamps and zipties and get on with things!

I thought I might just have a crown by day’s end, and I probably could but it would be cheating, becasue the longer I went on, the deeper the effluent I found myself in.

Homing X works today, but I trigger the thing manually to avoid the nest of zipties and it gets upset with me and says homing failed even though it clearly didn’t. (This is a repeatable error, not a one off, and it happens when using the V1 special menu as well.)

Then there’s Z which runs out of Z before it touches the endstops - a matchstick sized bend in gadget, or a tiny bit of plastic will fix that. (I need to drop the screw a little on the stepper axle too, but that’s not a biggie.)

Which leaves Y where everything is perfect and almost working as expected, except that I must have been standing on my head when I confirmed the direction the motors were travelling in, so I have to flip the “y”'s. They are both joined in the little carrier I made under the Z axes, so I’m wondering if it’s going to be easier to flip them there (it is) or whether to take it all apart and try to deal with the usb issue while I’m at it.

It might pay to do that because the Mk$ is arriving in a couple of weeks and I really would like to have this choofing before then!

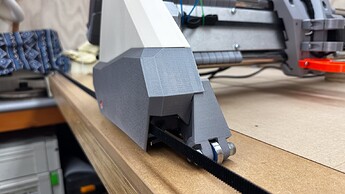

I cannot tell a lie, I was beginning to doubt whether the silver and cream was just too conservative, but the vanilla white Prusament is splendid, and even if the thing doesn’t go, it makes a lovely workshop ornament.

The fenders fit perfectly and really look to be part of the machine. (well one does - the other comes tomorrow)

My guess - possibly wrong - is that the firmware doesn’t like the manual trigger, since the automatic process triggers once, backs off, and then slowly moves the axis in question back to the endstop for a second trigger. I imagine it’ll work just fine once the zip ties go away and it can reach the endstop on its own.

Those things look amazing.

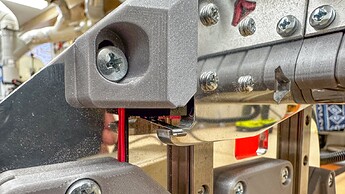

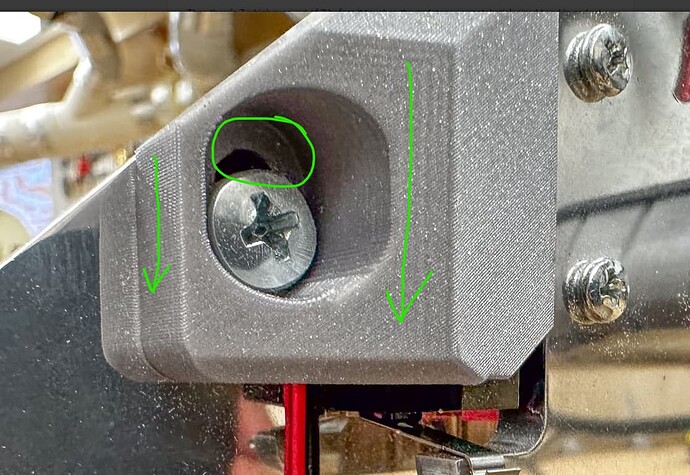

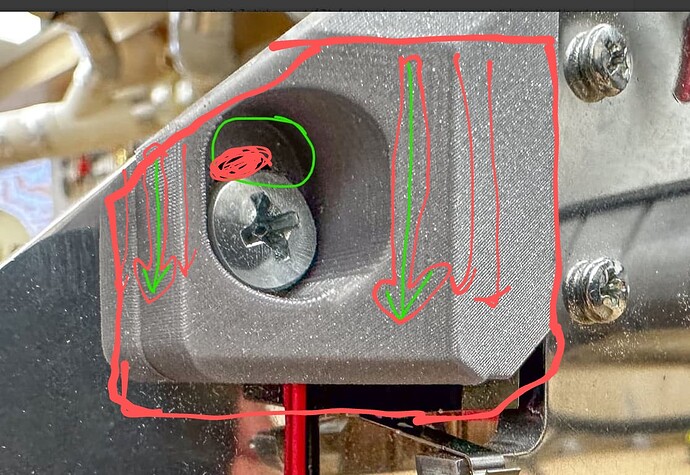

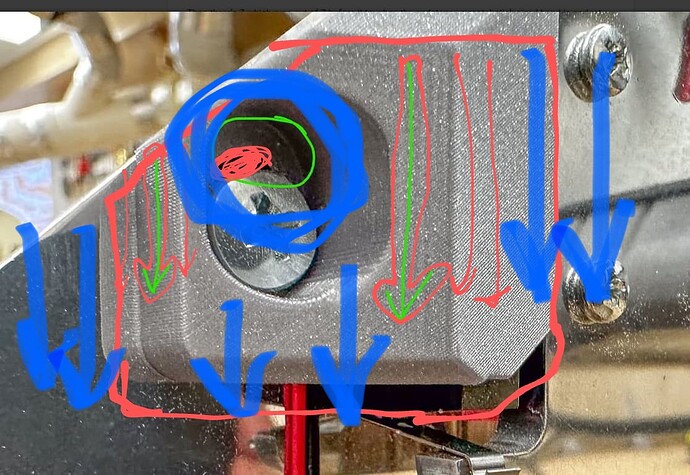

![]() That’s embarrassing, thanks for that. I thought I had them adjusted all the way down, the photos do not lie!

That’s embarrassing, thanks for that. I thought I had them adjusted all the way down, the photos do not lie!

I am afraid I am going to have to put that one down to a bit of brain fade. That and getting the Y axis back to front. Looks like my spacial perception super-power is starting to fade! ![]()

I love your imagining here, and I’m going to run with that! I question my own motives in publishing every little step here, but responses like this may well save me an hour or two of trouble shooting in exactly the wrong direction. Thank-you for standing by as well!

I don’t know if you’ve forgotten or if I’m overly anxious, or even if it’s tomorrow for you yet! (It’s tomorrow here, but I think it’s still yesterday for you!)

Will they be a separate upload or as part of the LR3 file?

Front Y Belt Base.3mf (48.5 KB)

Sorry I got sidetracked with some jackpot stuff.

You will need this one and a mirrored one.

I suggest mounting one side fully, and use jut the middle of the slot on the other one. This will let you do a rough adjustment on your squaring real easy before adding the second screw… Then you can fine tune it with your firmware settings.

Nice! Thanks for that - I’ll be able to get the thing square to half the thickness of a sharpie with my eyes closed!

![]()

![]()