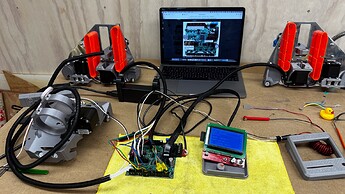

TROUBLE in Paradise!

Fixed by @vicious1 Ryan in less than twenty minutes - I’m blown away ! Thank you so much!

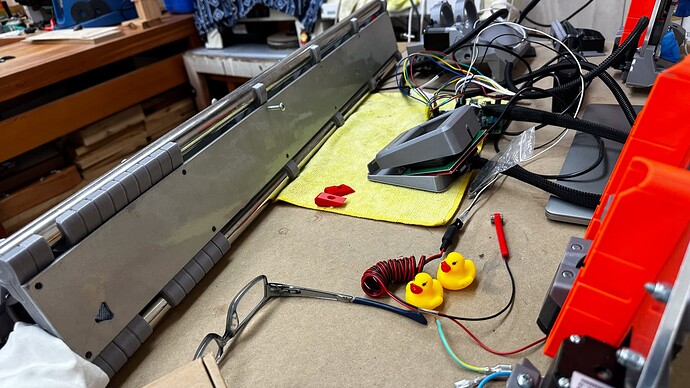

Well just when things were tickety boo, it’s all gone to you know what!  This is what happens when you try to get one duck to line up with itself.

This is what happens when you try to get one duck to line up with itself.

I guess there’ll be a short delay in progress.

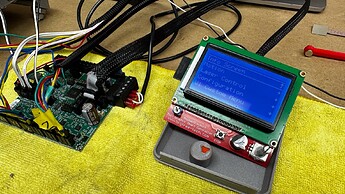

1) GRAPHIC CONTROLLER UNRESPONSIVE

I’m fairly sure everything is wired correctly and that it’s not a wiring issue. I think in all of my mucking around I’ve damaged the rotary encoder, is that even possible?

It feels normal and there’s no sign of damage on the soldered joints - but only the click works - which means I can toggle between the home screen and the next screen but can’t move to any other command.

Soldering in a new one may be within the limits of my skill set, but I don’t have a clue what to buy and in at our local electronics store the switch is about half the price of a new controller (no counting postage!)

Everything else appears normal, I reflashed the board a few weeks ago and everything was operating perfectly, today it’s not.

2) Well use Repetier you say!

Right well it’s time for the old “can’t connect to the Mac” messages. I seem to recall there’s a baud rate thing so went looking in the forum and the documents-

Either it’s my confusion or the docs are somewhat out of date (if I get through this I promise I’ll try to fix that, but I am so far out of my depth with this stuff that in itself would need someone else’s supervision)

So the docs very helpfully have this link -

Which takes me to a thread from 2016 in which are a number of dead links, and posts of code which I have no hope of understanding. But at the end of that thread there’s a neat post which takes me back to where I started.

Yes I am a bit frustrated, but not at the support - just my own inability to see clearly what I need to do.

3) How do I move forward?

The world is my oyster!

a) I’d like the thing to be working so the easiest way would be to replace the controller - currently not in stock.

b) I can try to solder in a new switch which may or may not work.

c) Is it possible to add a wifi unit and go headless with the Rambo?

d) Move the purchase of the Joker a long way further forward. (I was kind of hoping to wait till all the technical stuff had died down to a dull roar and there were clear instructions for the “rest of us”

e) in any case, I’d love to sort out the Repetier communication issue.

![]()

![]()