I had a bit of a day being a husband, so little progress, but since there’ll be no time at all till next week, I thought I’d report in anyway.

I’m a bit stuck with the assembly because there’s an IEC socket to go in the vacuum slot and it occurred to me that it would be quite embarrassing if I got it all assembled and couldn’t fit the plug in the gap, and there’s plenty of fettling to do in the meantime.

There are enough days left to have a chat about the torsion box and parametric whys and wherefores at some future date, but today let’s talk in generalities!

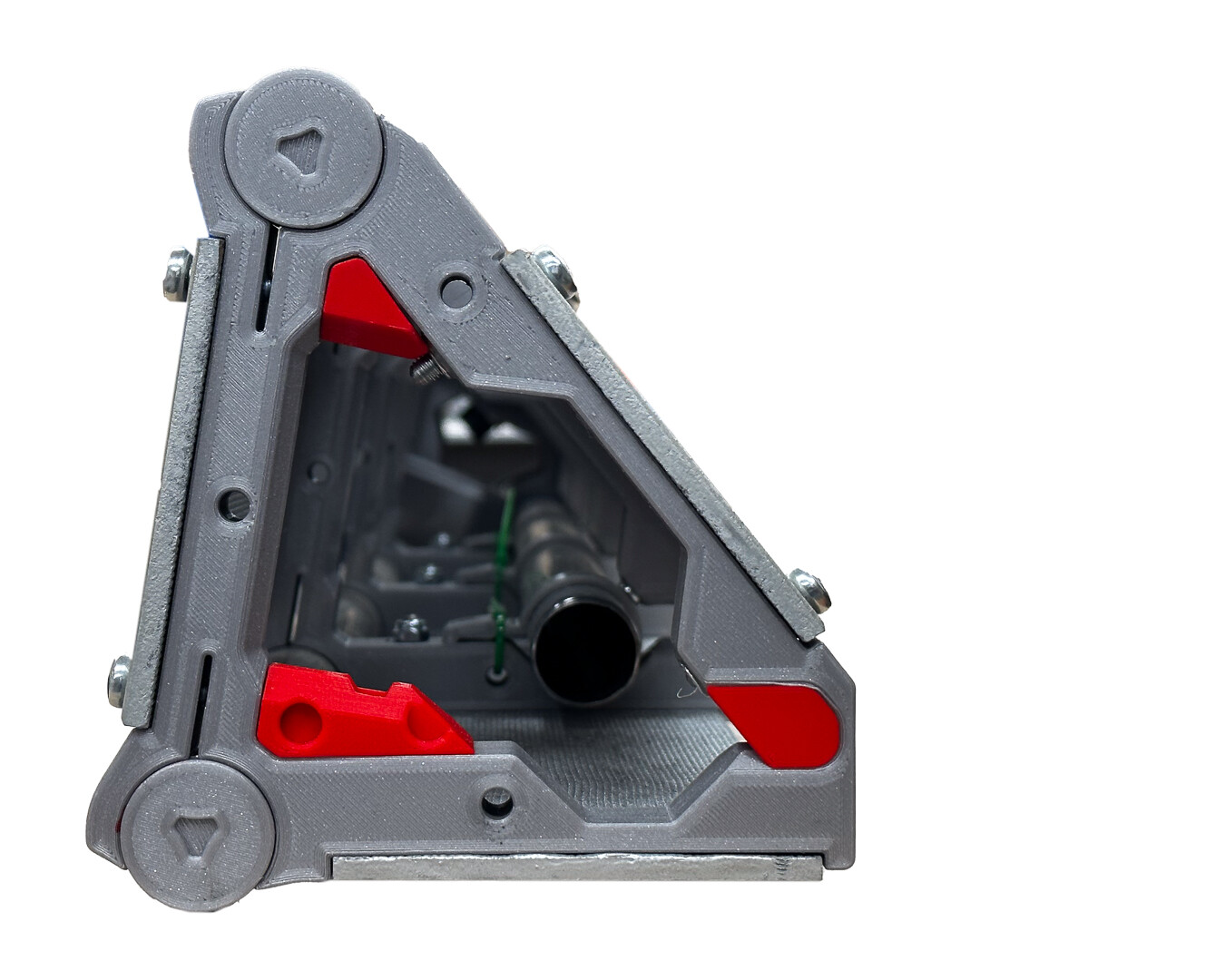

Here lies the backbone in all its glory. It’s upside down at the moment which means the drawer is inverted just to confuse everyone down the track.

The drawer is barely 2" deep but will hold spanners, bits and touch plate stuff conveniently. I’ll be using heavy duty slides and a tiny wedge at the front just to stop any temptation for the spoil board to sag in this unsupported bit. The drawer is 250 x500 or 10 x 20 in American so a 16mm spoil board should be OK until I drop a motorcycle gearbox on it midspan, or do something equally as stupid.

The vac slot looks over -elaborate and it might be, but if it works it will keep the hose off the wall, and it will also mean that I can build a complete enclosure at some time in the future, with the vac hose contained in it.

Electrically I’ll have a permanent lead running from power point through the table to the emergency stop to isolate everything. That in turn will connect to the machine through a lead with the aforementioned plug, so that the LR can be removed from the table simply if need be.

Router is plugged into the strut. I’d like to wire a relay to autostart the router at some point in the future, and that can go in the strut.

The E-stop just mounts in the face - it will be almost flush by the time I add the ply edge strips, so that it won’t catch on things when turned off. Through-mounting like this is super easy if you have a 22mm and 32mm Forstner bit - drill the 32mm diameter from both sides leaving three or four mm in the centre or offset to taste - then crank through with a 22mm hole, and suddenly you have a switch that looks as though it’s part of the furniture.

Edge grained plywood strips all round to make it fancy, or to give strange little horizontal ripples in the paint if I’m not happy with my joinery when it’s done.