We are real. ![]()

So you say… But what about all these other voices?

You hear them too? ![]()

The only ones that worry me are the ones that aren’t in any voice I’ve heard before. The others are either misfiring memory cells, or my subconscious surfacing something in a coherent way. Of course, after half a century of devouring a mélange of eclectic and far-ranging media, there are a lot of different voices knocking around in there…

Farewell old friends!

Why was this so difficult - the final farewell? I thought I could just hang 'em up somewhere as a memento, but I think I’d rather remember them when they were in their prime.

In the meantime - two down and one to go. These removable casters work a treat, I highly recommend them. Of course that’s the one with the lathe on it, and I’ve been putting off rebuilding that one for a decade. It looks as though progress on the machine might have stalled for a day or two.

Friday I just tossed the ones I had here. I keep on assembled for the museum box and it was still hard to toss the rest, it took me months to actually do it.

I’d like to say that I was back into it, but you blokes are keeping me thinking about other things, and I have had to have a few intervals while the glue dried as I assembled my entirely rebuilt lathe bench.

I can report that the car fits in the garage again, so there is evidence of progress. I’m not sure what I’d do if I didn’t have a two car garage!

And the spot for the LR3 is now longer and wider by just enough to fit a 1600 x1200 table which will give me a cut size of around 700 x1200 and proper space for the vac hose to run. It seems hilarious that those tubes came from the LR2 which fitted that table exactly.

And on another note but slightly related. I came across this image of one of my benches taken eight years ago. I’m posting it here as a reminder that though it was built with no less care than I’m presently putting into the LR3, it was never a piece of furniture, it’s a tool to be used, and like the LR3 no doubt will in due course, this bench cops a flogging daily.

Cars have paint to protect them to stay outside. Motorcycles don’t so they are allowed in the garage. The garage is the workshop. Damn I wish i had a garage…

You think? This is a pic of my bandsaw case, kept inside in front of the car and under a cover when it’s not in use, treated with anti-corrosive substances every few years to try to keep the corrosion at bay. All my gear looks like that!

Can you imagine what a car would look like after a year or two outside in that? The bodywork would be gone and it would look like… ![]()

Two motorcycles! ![]()

![]()

I am not saying you don’t have to maintain the car…

Look what I found under my workbench - my old analogue CNC machine! After ten years wrapped in a bit of sheet, it cleaned up almost as good as new.

It sold on marketplace in an hour. Who’d have thought?

Good news, bad news, a bit of a mystery.

The good news first; I’m within hours of completing the tidy and re-shuffle of things in the shed. “Reshuffle” meant moving some benches a total of 300mm to allow for the LR3 table, but that in turn meant unloading everything stacked beneath them most of which has been there for a decade “until I have time to deal with it”.

Then there’s the benchtop detritus which falls into the same category, my least favourite job and it’s down to just a few odds and sods that have to find a home.

Why though, am I haunted by random tent pegs? I’ve never owned a tent peg of this cheap variety, and when I do buy pegs, they are immediately sharpened and dipped in yellow enamel almost before they are packed away, yet whenever I tidy anything, one of these turns up?

Now the bad news - well we’ll be away for another week so the LR3 and all it’s bits will continue to reflect the state of my mind while no one makes progress in my absence …

Watch this space… ![]()

Back in the swing of things after a week of doing not much but catching up with friends in various parts of the country, and somehow all non-build-a-cnc jobs have multiplied while we’ve been away!

On the face of it I could have the machine running over the weekend, and I was going to do that and build a temporary table to check out how my vac hose thoughts would work out. Instead, I’m going to launch into the final table top and a few other jobs while I’ve got the tablesaw clear.

It’s odd documenting stuff “as I go” because there’s no room for error - but it’s nice to have people to cry with when things go wrong.

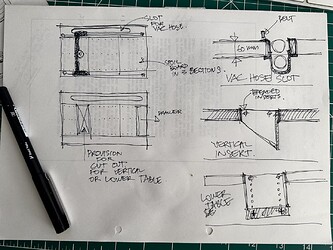

Here’s the plan:

I’m going to build a “proper” torsion table 60mm thick with 3mm skins because all the benches in my shed are the same height, and that’s how much depth I had for the LR2 (with the max 100 thickness) and I’m not going to re-build the platform on which it sits.

I’ll incorporate a drawer in one end, and with some reservation “make provision” for a cutout in case I ever want a deeper table or to mill the end of a vertical drawer or something. I won’t build it, just make a gap to be cut out later, and locate the threaded inserts.(t-nuts)

The reservation comes because, long before YouTube was invented, I did something similar on my drill press table and it’s been used exactly zero times in the intervening period, but it’s a handy storage spot for the vice.

The spoil board will be in three parts, because the home corner is going to be much more likely to need replacing before anything else.

The vac hose will run in a slot built in. In reality this costs only an inch or so and will just make it tidier and a little protected against pushing against the wall - I may or may not add printed brackets below so the hose can run back on itself and stay off the floor.

Questions and specially criticism will be welcome - construction may start tomorrow!

No, I haven’t started on the table, but in the last two days I have painted and rebuilt a couple of bedside tables, ordered some lounge chairs (delivery from Norway takes longer than from the USA, but at least I’ll have till next year to save for the other half), received a few kilos of filament from Prusa (5 days from order to doorstep! ![]() ) which means I can burn through some more Galaxy Silver, and now have some Vanilla White for the fenders, ordered my Mk$ err sorry, Mk4 and have spent an inordinate amount of time reinventing vacuum fittings.

) which means I can burn through some more Galaxy Silver, and now have some Vanilla White for the fenders, ordered my Mk$ err sorry, Mk4 and have spent an inordinate amount of time reinventing vacuum fittings.

These are just final prototypes so the print is a bit rough, but tomorrow I’ll upload a suite of Ryobi-to-various-things plugs.

For reasons that I can’t explain other than I had some longish scraps that were too good to throw out, I thought it would be nice to have a nice end-grain laminated plywood trim around the edge of my table.

I’m also attempting to assemble the TV cabinet bits I’ve had hanging about for a rather long time, but I thought I’d get the last ply strip glue up done this morning.

Oh dear, I’ve got glue on my assembly bench - don’t want to risk staining that oak. Oh well, back to work on the LR3 I suppose! ![]()

The “old dip it in hot water trick”.

I was thinking I might have to reprint my hose hangers so that my new fancy hose would fit, but a few seconds in boiling water makes even solid PLA do exactly what you ask it to do.

Before on the right, after on the left.

![]()

Heat gun can make it compliant too

I too was going to meantion the heat gun. I seem to be able to control that better, and not cause discomfort with hot water to my fingers.

I use the hot water for the “annealing”. (I put that in quotes, as I’m still confused on if people are using that correctly. Oxford dictionary implies Peter IS annealing. But what I’m doing and most other people with FDM prints, aren’t normally reshaping, as much as ensuring that the layers are bonding well, and becoming one. Which by the definition, they are using heat, but without reshaping, is the material being worked?) ![]()

![]()

Yes indeed, but be careful with the heat gun on solid parts - boiling water is a great way to ensure you don’t overheat it and can control exactly where the heat is going.

Totally agree. The heat gun’s benefit is the speed and convenience. With the “concentrator” tip I have on mine, I have some better control over where the heat goes. But you do have to be careful, especially if it’s on high. You can melt the plastic quick!