Man, that cover/fender/shroud/what-have-you is so slick! Loving this whole thread, giving me lots to mull over as I’m starting out.

Thank-you, but please don’t be distracted by my obsession with tiny details that don’t matter at the end of the day!

Don’t let it derail you from whatever your real objective is - if you want to get going and making things with your LR3, just get on with it and add the pretty bits later.

On the other hand - if you wait a week or three or five, or eight (I’m not that good at deadlines! ) once I’m happy that my parts can be built by someone else I’ll happily share them all.

It’s not just all the pretty bits… although I definitely love blinging out my tools with fancy but functional parts (see also: my 3D printer). It’s the whole build/design maker thought process that appeals to me.

I won’t be ordering the parts kit until next paycheck. In the meantime, I’m contemplating the various design decisions that I can make right now, knowing full well there will be more decisions as things start coming together. Like many others, I’m not just in it for the finished product, I love building the things as much as I love using them (see also: my five drones). And maybe this will also finally push me to start learning CAD in case I want to design my own parts, too.

You will not regret that! Learning to use CAD changed the way I think entirely.

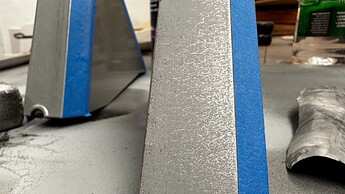

And now… back on track, I have reached yet another point of no return - those covers are such lovely prints I’m terrified of not doing them justice, and knowing how impatient I am, I thought if I can just squeak on the primer and a light filler coat before we go away for a few days, I have a chance of it being fully cured before I sand it.

I’ve always had great results with Dulux DuraMax - but there are lots of special plastic primers around and they all seem to work OK.

My last can of spray putty was running low, so I committed the unforgivable sin, and laid on one thick coat. The base was so good that hopefully I’ll get away with it but I’ll have to be a bit careful with those sharp corners when I’m sanding.

Listen, Frodo…

Nine hours ago, I said I’d packed up for a few days. Well it’s 8:30 pm and we don’t leave till the morning and when it comes to the sort of patience you need to watch paint dry, I’m hopeless.

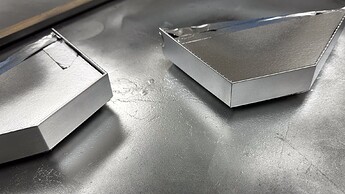

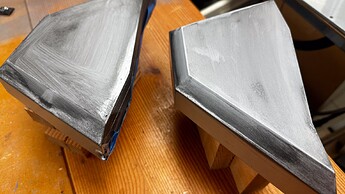

A quick rub with some 400 grit and a splash of satin black undercoat later - (photo taken before the paint had flashed off to show the imperfections in the print), now we can leave it for a few days.

It’s not perfect and the filament lines will print through eventually, but that’s OK in the same way that the polished aluminium is a two metre job, so is this. Once it has a few more rubs back, a couple of coats of silver and a few clearcoats later it will be just fine.

It has to be, I don’t have any more spray putty! ![]()

I did something similar with aviator plugs and it’s working great for using the router in and out of the machine, it makes tramming a more common occurrence but it’s worth it for me as I don’t have to buy two routers.

I had about a day and a half to make some progress, so I spent the first of them making sure that by the time tomorrow lunch time comes around I will have gone backwards by a week.

Some days are golden, and some days aren’t.

The side covers were looking almost ready for a top coat, but I thought I’d do a little touch up job with some spray putty without giving a thought to the fact that laying solvent based paint on top of acrylic is not what the smart kids do. Ever. So there’s a bit of sanding to do till we get back to where we left off.

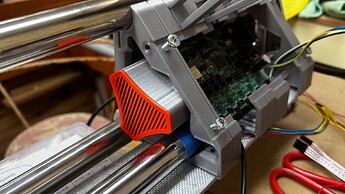

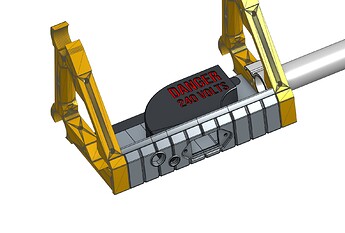

Speaking of the smart kids, they aren’t the ones attempting to mount their Rambo boards in the beam either are they? I’ve seen fishes bums that weren’t this tight. What I wouldn’t give right now for the freedom of that extra 25mm the new Joker would provide!

No matter how I tried to convince myself, I just can’t get the passthrough USB plug to fit into the space between the braces, so it’s going into the brace into the one spot that it doesn’t clash with anything, but I have to extend the little patch cable out of the enclosed space to make it work.

That was disappointing, but I came up with a nifty extension of the vent panel that will enclose it nicely and set about to print it. Too lazy to clean the build plate after a weekend away, too preoccupied with other things to bother with a brim, I guess I deserved my first failed print in months, when it came unstuck while I was having a snooze.

Ahh well, onward and upward!

I thought I’d get all the wiring done today too, but I’ve spent a terrible number of hours just staring at it all and marvelling at how simple it will be if I ever get started.

Doesn’t time fly when you are having fun.

It’s pretty much bed time now, and it looks as though I’ll be able to start tomorrow exactly where I was when I started today!

LOL bedtime for you and I’m just getting started here 0645

Will someone tell me when I’m having fun? ![]()

![]()

At some point I’m going to toss in the towel, print them a nice vanilla white and call the covers done!

This morning I removed the neatly applied masking tape from the fresh paint surface to discover that I’d left it on a bit long or I’d used exactly the wrong sort and it left the glue behind. So I got out the trusty bottle of white spirit (mineral spirits to some?) and before you could say “Hey isn’t that what you use to clean graffiti off things?” I proceeded to dissolve the tape glue.

Just looking back on this thread, I think I’m about where I was 6 days ago! ![]() At this point I’m not sure if my paint is ever going be finished.

At this point I’m not sure if my paint is ever going be finished.

You could be at work instead of working on your hobby… So id say you are having fun!!

Thanks for the updates and the pics!

I know this is a long and garbled thread, but hopefully it will document the “real” building experience (notwithstanding my constant deviation from the plan.) Perhaps there’s a chance that some might even learn from my mistakes and ramblings. If ever it comes to a conclusion, I’ll probably make a one-post summary thread!

Every time I start to get my ducks in a row of late, the little buggers swim off in the opposite direction!

I’ve had a procession of little bits arriving over the last few days, which is good because that means I can get to and finalise the last of the custom parts and I have one parcel to go and I’m almost ready to make some real progress.

Just now though, for the first time in 3,000 hours, my printer has a clog. My fault (as most things to do with printers misfunctioning are) - I was just a bit careless removing filament on a change and have a hotend full of filament that doesn’t want to go anywhere. It might also be a sign that the little PFTE tube is due for a replacement. I have a spare, but absolutely no enthusiasm for giving the printer a proper service, which is long overdue.

We’re off for a few days again, so I think I’ll attack it with a fresh mind and attitude on Tuesday when we return.

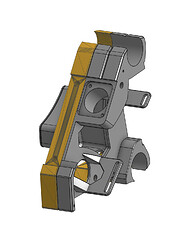

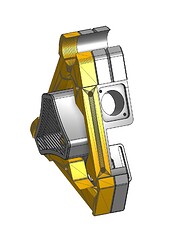

It’s probably not been a bad thing just concentrating on drawing stuff ready to prototype and print next week, because fitting in the passthrough plug for the USB cable was more complicated than I would have liked which of course leaves a lot of places for a tiny but insurmountable error that can only bite during assembly.

Despite appearances it’s an easy print, and it’s all concealed beneath the strut, except for the slot (or maybe a circle for the entire socket, but I just don’t like where it’s ended up.

On the other hand, the 240V side of things will be quite tidy.

It’s been a long Sunday afternoon after a VERY long Saturday night celebrating our youngest baby’s fortieth birthday… :![]() and we’re still a day from home, so I’ve had plenty of time to think about where I’m headed with this build and the more I think, the more it hurts!

and we’re still a day from home, so I’ve had plenty of time to think about where I’m headed with this build and the more I think, the more it hurts!

-

I’ll be picking up the vac hose tomorrow, and suddenly wondered if, since I’m going to run the vac hose to the “other” side (rail side) if it might not have been a bad idea to print the core mirrored?

-

For the same reason I may have dodged a bullet by deleting the exposed box - at least there won’t be a clash with the vac hose, but my rack for the controller might be problematic.

-

I’m very tempted to order some “vanilla” filament and just print the top covers with that, and run with the original plan - vanilla top covers and polished struts. (mirror finished composite (if I can get it).

The obvious solution is to stop thinking!

HOW FANTASTIC IS THIS??

When I arrived home on my porch, I found a parcel that I had been tracking from the USA for a couple of weeks.

I am not sure if it’s cool to mention the person concerned, but he and I know who he is. Not to put too fine a point on it, he was quietly appalled at my rusty bearings pictured above, and took it on himself to foist a set of stainless steel ones on me so that neither of us should fret again at my tardiness.

All I can say I am overwhelmed, overcome, overjoyed and over the moon at this extraordinary yet greatly appreciated gesture!

Watch for little specs of blue appearing as my “final” build begins to take shape, and nod in the knowledge that now you know the reason why none of those nuts were tightened the first time round!

Cool, just a small warning (based on your description that won’t be the case but anyways); I ordered similar ones in blue on Amazon.de

The bearings were too much loose I just reinstalled my older ones. You could twist the shaft from the body few degrees. I only figured it out because I couldn’t get rid of the rattling sound.

So that was rubbish for our lovely CNC.