You sir are the man!!! Thank you!!!

Wait, why is it taller? That is cutting into the usable area and cutting down the rigidity by moving things further from the surface, and needing to hang an endmill further out of the collet.

If you are worried about airflow you should just open the channel on the bottom more. Moving it up twice as far means half as rigid.

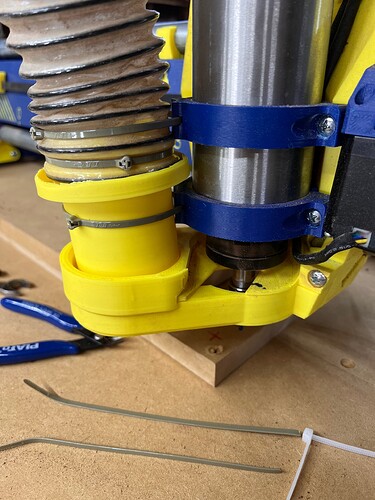

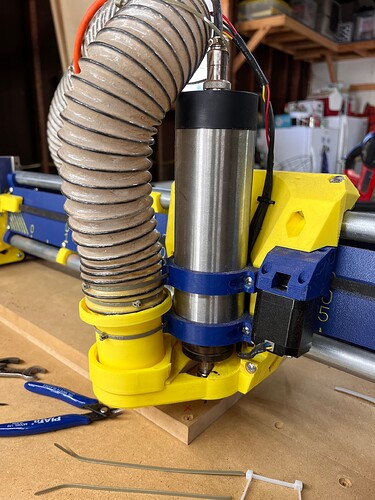

I have the spindle as high as possible on the mount and the collet hangs a good 1” below the dust shoe. Because of that I wasn’t getting good suction on shallow cuts. If I was going to cut into 3/4 plywood then I wouldn’t need the lower mount. I will print all of the new ones when I get home and be able to use only what’s needed for the specific job

Would remix of the spindle-to-core mounts to seat spindle higher help avoid need for deeper vac hose mount?

Very possible. Right now the lowest part of the 65mm spindle is even with the bottom of the bottom mount so no way for me to raise it any higher and still be secure.

Also I have been meaning to mention this and get anyones opinion about it. I decided to print the 2 mounts out of asa instead of pla. My understanding is it has the same rigidity as pla but much higher temp. I know I print pla+ at 200°C and the ASA I printed at 250°C

The collet should line up 2 mm below the lower edge of the Core. That will give the the full range of motion.

You can make a mount that is one piece so you can put the spindle up higher. To be honest though, that is a pretty drastic overkill. Having 3x-4x the power is starting to get offset by the weight and loss of rigidity.

If you get the collet lined up to the bottom and use a suitable length endmill the boot works very very well as is, even with a 1.5" hose. If you have to use too long of an endmill a dust skirt is a good option.

ASA is close PLA is still more rigid. ASA has the drawback of unhealthy fumes and warping.

For the tool mounts, though, they are basically belts and any material will hold sufficiently well. Rigidity comes into play most with the core and the X stepper mount printed parts.

This is only a 1.5kw spindle so not even twice the power. I believe the Mikita is 1.25 hp and this is 2 hp. And I don’t thunk it weighs much more than my dewalt 611 did in my lr2 but I will look that up to be sure. What I see the big difference being and what I’m running into right now is the collet hangs a lot lower out of the bottom than it does out of the Mikita. I’m going to give it a shot trying to remix a mount. I know nothing about doing it but hopefully I can find some YouTube videos lol

Roger that. I went with it for the temperature since the spindle does run a little warmer than the router. But honestly it not bad. The one I have in my primo is in pla mounts and doing just fine

Ok i had some time to mess with this a little this evening. Now i have no way to test it or even measure how high i can go from work so go easy on me lol.

https://www.printables.com/model/360285-lr3-65mm-spindle-mount

Basically all i did was raise it up 20mm and put a 1mm fillet around the edges (that was the closest i could tell from what Ryan had originally done). If you much more experianced guys could tell me if you think this will work. Hoping this will give me the room to bring the spindle up higher and get the collet from hanging so low.

For anyone wondering this is “work”…

Second photo is crappy but i dont have a ton of pics from off the boat that show the full length of the legs. Friend of my was on another boat and sent me these when i came in last hitch.

That might work. It would be better if you just connected mine from the cad. That way there is no room to flex open.

![]()

What the heck is that. Is it a boat / forklift?

I will give that a shot tomorrow. Still learning lol.

Edit: Wait a min. I thought i did use yours. I got the .step file from printables. Had a raw block and the makita mount. I have no clue where to start with the raw block. But i did know how to extrude that one taller lol. If anyone has any helpful youtube videos specific to this type of remixing in fusion360 they could share that would be awesome. everything i have tried to search has come up blank. at least for what i can understand currently lol.

Its a liftboat. We use them in the GOM mostly for oil/gas work. We go out to the platforms and jack up next to them. Give whatever contract crew is doing the work on the platform a place to sleep and eat, a deck for all of their equipment and 3 cranes to assist in moving whatever they need around. Legs are 245’ long. Boat is 95’ wide by 145’ long. We sleep 46 people. Largest crane is 175 ton. I will look around for some more/better pics tomorrow.

If you open the makita mount I think it has a cad link, should be a complete file. From there, adjust the diameter and connect the two.

It could also be the timeline just need to be rolled forward on the bottom of the screen to get to the finished mount. If I click the link I shared I get my current file, not the file you guys see. So I am not really sure what is there. Fusion is not all that good at sharing.

I am hesitant to make the file for you as I don’t want to encourage people to get that spindle.

DUDE, I had no idea something like that existed. That is freaking cool.

Only thing i have seen is the .step files but i could totally be missing it. I just messed with it again and i “think” i accomplished what you were trying to explain. I added 2 more files to the printables link…

I hope i haven’t come across like i expected you to make the file for me. I want to learn how to do stuff like this. I just wish there were better tutorials for it. But seems that even the videos ive watched that had nothing to do with remixing were able to give me at least enough knowledge to put the 2 parts together and look somewhat correct lol. I say that now before you’ve had a chance to look and tell me how wrong they are lol. thats ok though… all part of learning. I am curious what you have against the spindles though. Im not trying to run it any harder than i did my Dewalt in my LR2. And its insane how much quieter it is. I just need to figure out how to get RPM reading from the VFD either into the SKR pro or into a separate screen so i can hopefully tune the bit even better.

Yes sir. Ive worked on them with as little as 100’ of leg up to this 245 now. We have 2 of them with 335’ of leg as well that sleep 135 people. I dont want anything to do with those lol. too many people causing too many headaches to deal with lol.

The link is the cad file, Fusion

From this mount, Printables

File looks the same as what I was using but i didnt inspect it that close. But i was able to combine your blank one and it seems its already at 65mm which is what i needed. Added to printables so you can inspect…

https://www.printables.com/model/360285-lr3-65mm-spindle-mount

I do think im going to have to do the same thing to @DougJoseph remixed mount since i believe he moved the vacuum mount over some to accommodate the 2.5" hose.

Yesterday, I remixed @DougJoseph’s makita-tool-mount 2-1/2" remix of the original LR3 mount. Thanks Ryan and Doug!

- Doug’s remix rotates sticky out bit that makes contact with the vac hose by ~5 degrees and modified sticky out bit’s curve for 2-1/2" vac hose.

- My remix (sketched and extruded in Fusion 360 by tracing Doug’s .stl imported as a mesh) increases zip tie hole height from 4mm to 9mm to accommodate reusable zipties I have.

Shared .stl and .step files on github and printables incase that helps…

Awesome! Thank you!! I think thats exactly what i needed. Hopefully Ryan agrees lol. I uploaded them to the link above. Forum doesnt like me posting the same link repeatedly

My logic on this taller remix is for only temporary use (snap on snap off) only whenever the planned work is very shallow, and the bit is as far up as you care to put it, and you still want to get the dust shoe closer. Given @Jonathjon’s specific use case, it seems like it might be needed by him more often than most others. It was not a heavy workload to create the remixes. As long as folks understand the limited use case scenario it should have a valid purpose.