I’m going to have to make some adjustments. I made a piece for my wife tonight before I left. 12” x 12”. The side on x- cut great. X+ didn’t quite cut through. I think I was making too many adjustments trying to make it perfect and ended up getting it worse lol. Need to just start over and not try to get it perfect spot on.

Interested in a link for this. I hate paying prices for adapters

Thanks

If you are cutting through- that’s what a spoilboard is for. Add a couple though to the cut depth and you’ll be good. In a few months, you’ll also have a nice abstract piece of mdf to use as wall art in the shop, lol

Vacuum_Hose_Adapter.zip (937 Bytes)

Open.scad file, I do all my adapters with it.

I did add extra. It just only made it though on one side. When I sold my LR2 that spoil board had some DEEP cuts in it lol. Trying to be more precise and learn better with this one.

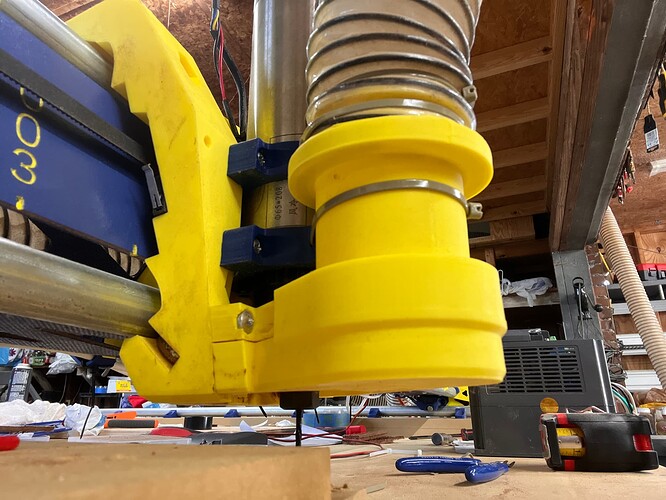

@DougJoseph this is what I was talking about last night.

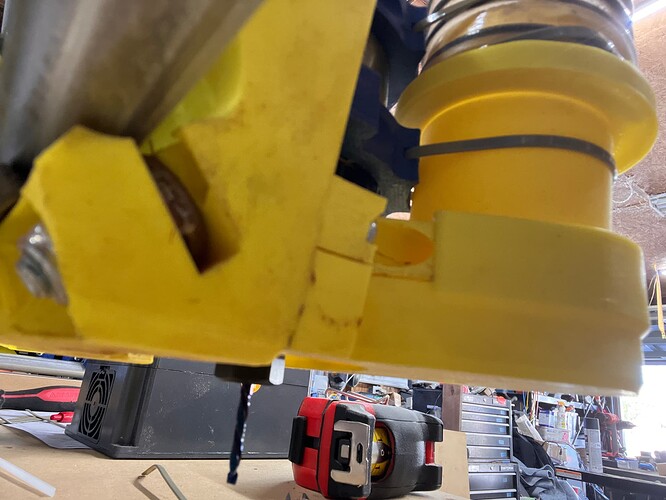

Not a problem with you’re design in any way and I hope I didn’t come across that way. I would imagine cutting thicker material it would get closer and work much better. It has tons of suction. Just too high above the dust lol.

Yes, as far as the height positioning goes, my remix is exactly the same as the original part designed by Ryan. The height issue is related to the dust shoe being bound to the Z movements of the whole gantry, and thus unable to adjust for whether your bit is cutting deep or shallow. To allow for the latter, then the gap for the former is considerable.

I wonder if I could 3d print a tpu brush and super glue it to help direct more of the suction downward…. I know I have seen brushes printed this way before but never tried it myself. I did convert 2 of my printers to direct drive and have wanted to try tpu so this may be a good excuse for it lol

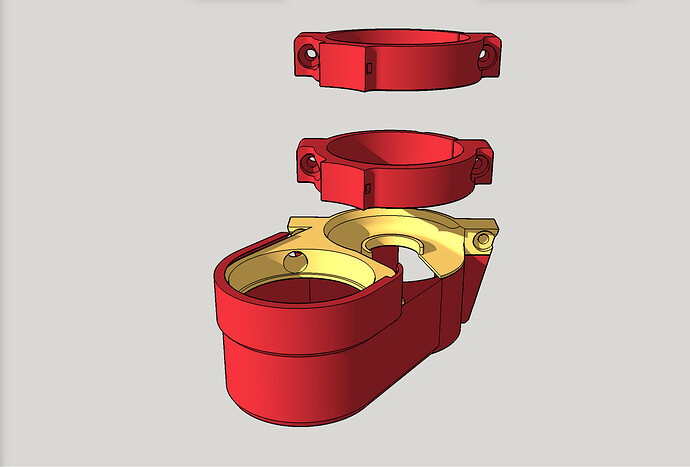

I’m sure that’s totally doable. My thoughts are that in order to protect your ability to go deep, in which the bottom of the core (and existing dust shoe) is nearly on top of the surface of what you’re cutting, you may want to make any “Add ons” that reduce the clearance, as a removable thing. The easiest way to remove is by magnets being how it was attached. A remix of the bottom part of the dust shoe could allow places to press fit and glue in magnets. Just a thought.

I think that would be a great idea. Only issue I have is my remix skills are nonexistent lol. It is something I need to learn.

To remix for that, the fist question is what magnets to use. My first thought on that, is I used some powerful little round neodymium magnets for this LR3 related project I did:

LowRider 3 CNC Plasma Torch Mount with floating Z and magnetic breakaway, prints without supports (v1.2)

… and therefore if I planned for those being what is used, I already have the existing geometry for the press fit holes. ![]()

Products used as shown in video:

- Round Magnets — 12mm x 3mm (actual dimensions ~ 12mm x ~ 2.8mm) — shown in this video — quite strong, and can be used for this type of application, working great — MIN CI 100Pcs Super Strong Neodymium Disc Magnets, 12 x 3mm Small Magnets for Dry Erase Board Whiteboard Office Fridge Crafts, Mini Round Rare Earth Magnets for DIY Building Scientific Models

Yes I have been following you’re plasma build and those Amazon magnets should work great

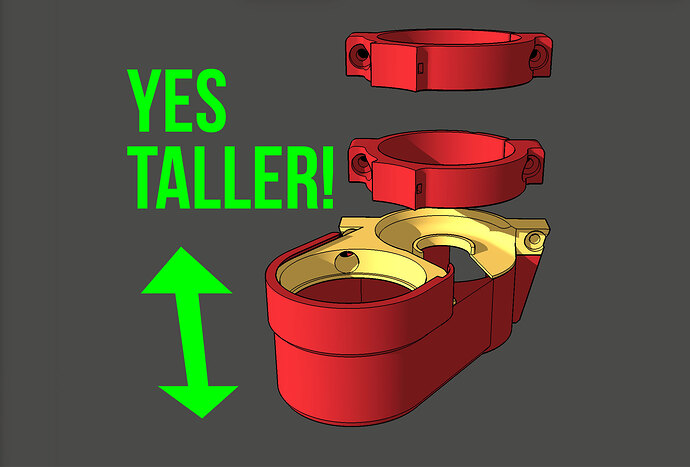

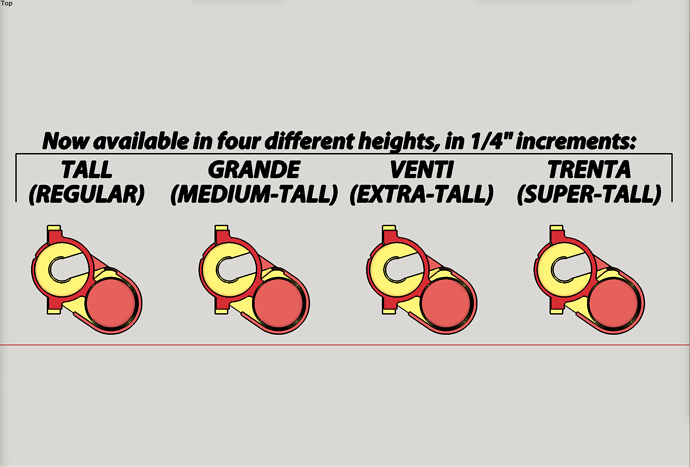

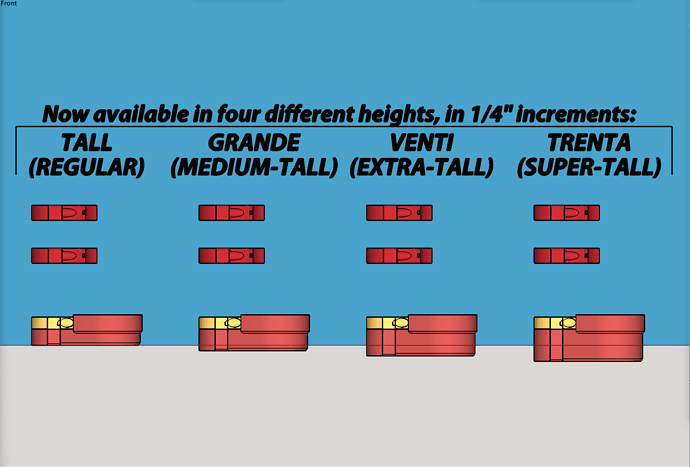

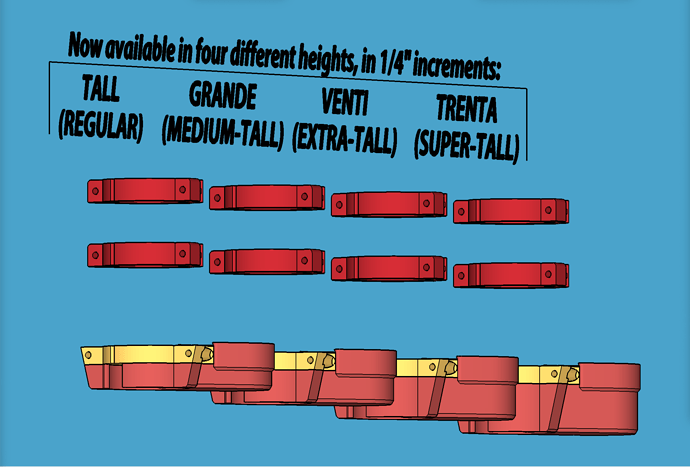

On closer inspection, the “air scoop cup” part of the shoe, is already a removable thing. All that is needed is to have more than one version of it, say, regular, medium tall, and extra tall!

I am currently making a remix that offers 3 taller versions, in 1/4" increments.

@Jonathjon, nice front grill strut ![]() Appreciated reading through your build journey.

Appreciated reading through your build journey.

@DougJoseph, should folks with Makita still use the existing one at LowRider v3 - Makita 700 Series Mount & removable dust shoe - REMIXED FOR 2.5" HOSE (v1.1) ? Are the additional 3 taller remixes only intended for spindles with collets that end up being lower?

Appreciate the info, literally about to print off the lower dust shoe lower part. Cheers!

Q: Should folks with Makita still use the existing one?

A: Yes. The taller ones are intended to be swapped in only when you are doing non-deep-cut jobs and want your dust shoe temporarily lowered!

Q: Are the additional 3 taller remixes only intended for spindles with collets that end up being lower?

A: These are intended for anyone who has need or want of a slide-on/slide-off scoop part of the shoe that is temporarily taller to get down closer to the work surface.

That is awesome! Thank you so much for that!!! Now I just have to wait 2 weeks to be able to print and try it lol