I was considering upgrading my LR2 to LR3, and I had an idea the other day… it’s a bit crazy and I don’t know if it’s worth it…

One of the Lowrider’s specificity is that it’s… low… and the lower the strut is, the stiffer the frame is

What if… we made the whole Z assembly rigid? Fixed at a certain height…

How do you plunge and cut then, you ask?

I have this Triton router I use for “classical” woodworking, and it has a mode where the router keeps the plunge depth you set it at, and won’t go back up until you turn the adjustment knob

Also, it has two adjustment knobs: one in the handle, and one for micro-adjustment on top…

And this second knob also has a nice little stub on the other side you can catch on with a pole (for when you mount it under a table… so you don’t need a lift)

Maybe I could hook up a stepper to this micro-adjustment knob? and then I’d have my Z axis, although the whole Z assembly of the lowrider is fixed…

Just like the system you find on a Maslow CNC…

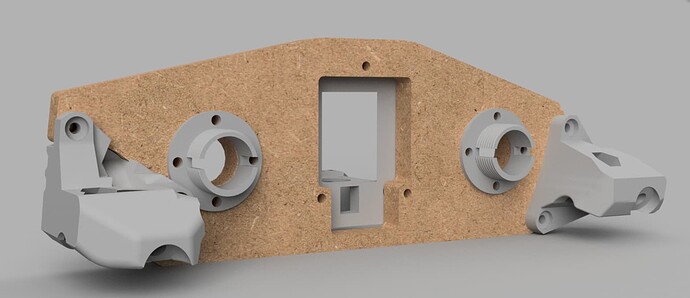

The mod would be kind of a frankenstein between LR3 (riding on a tube on one side, wheels on tbale on the other… using LR3 rollers…) and an LR2 (2 horizontal tubes with the router in-between on a cradle, using 4x LR2 rollers on the cradle)

I started a rough mockup design of the side plates (single side plate, no linear rail, no z motor… added two 25mm holes and clamps pour the X axis tubes…)

I’d like to have your thoughts about it, is that a totally dumb idea or does it have a chance?

Since it will mostly use parts from the LR3, I guess I can try anyway…