Yes exactly that, thanks.

One other possible approach, would be to extend the shoe down and then place a magnet on the linear guide that grips just enough to keep the shoe down, but can be slid upwards as the shoe gets pushed up by the process of “sledding” on the material.

Doug after using mine for the last 20ish days I would sag that a little wider opening wouldn’t be a bad thing. I had a few occasions where it got clogged

I will try to look into that.

So, I checked again just now, and the limitation to how tall the wind tunnel in the shoe can be, is the limited space between the bottom of the router and the bottom of the LowRider core. While there is a “shield / guard” still present in my design, which could possibly be removed, that would gain only a couple of millimeters.

The previous version of shoe, which had a thinner bottom because of only having bristles at the outer perimeter, had about 5 more millimeters of height available to it. I could again re-publish the ones of that version that had wider openings at the bottom!

I updated the v1.0 listing on Printables to include the shoe versions with the wider openings at the bottom again.

https://www.printables.com/model/558203-lowrider-v3-floating-z-dust-shoe-and-makita-router

I updated the Change Log as follows:

- December 6, 2023 — one V1E maker has an issue where his dust collection suction is so strong that the floating-Z shoe keeps getting pulled upwards by it. I offered to re-publish the shoes with wider openings, in hopes it could help him. As such, this design now offers all three of the earlier shoe versions, including option “A” as “¼ open,” option “B” as “½ open,” and option “C” as “full open.”

Thanks Doug. I didn’t have a problem with the suction not letting it go down. I believe that’s because I don’t have that extra shorter piece of hose in there with limited room to move. I think just a little larger opening would do wonders. I did print a full open from the original listing and ran it when I did my surfacing. I would get these “strings” of mdf that would block the opening on the newer one but the full open had no problems. I do think the newest one is better supported with the extra Eva foam. It doesn’t fall flat like the original. I might see about remixing your half open and see if I can add another rib of foam in there to help it not just flatten the foam and ride on the work piece. If I ever get time lol

I have found that clamping a board that is roughly the thickness of the exposed spoilboard and butted against the spoilboard prevents the sudden opening beneath the dust shoe along the front edge…

Cool. Neat idea.

Thank you for this. As I type, I have mine in service planing the top of its table.

Do you happen to have any plans for slightly oversized mount rings to accommodate the tramming insert rings? I spent the better part of the morning trying to tram my router with tape. It’s better, but I do like the idea of tramming with the eccentric rings. Not sure if there is room in your tight design.

Oh - and thanks also for the kinematic mount. I used it to burn some artwork from a late relative for gifts for his adult children.

That’s definitely an idea that could be pursued, mashing up this plus the tram routing system. If you get a chance, post pics and etc. as makes over on Printables!

I know this is a bit old, but I have some insight to the difference between the big and little systems that I am sure Chris and Doug are aware of, but is worth stating for those trying learn more on the subject.

static pressure vs air volume

a shop-vac or the like doesn’t move that much air, but works by creating negative pressure (vacuum) and actually sucks the dust. This is why vacs have rigid canisters between the impeller and the hose. The motor moves air out of that rigid canister and creates the vacuum.

dust collection systems have far less to 0 vacuum, but move so much air that the dust gets caught in the air flow. That is why dust collection hoses are much more flexible. They don’t have to resist the vacuum to be effective.

Your observations about the hose getting sucked in with a vac is a non issue with dust collectors.

@spsully2582 Thanks, and great observation!

Yes, that is 100% true.

The system i was playing with was a pressure or vac pressure System. The do create a lot of suction.

And you are also correct regarding the traditional dust extraction usung volume.

My system was based around the suction as i could get the parts for free or close to. As i said in the other thread there is a brand (cant rememeber the name name) trying to push these as an option. But in australia you are better off price wise with the traditional style.

My only observation sofar in favor of the vac style is the size of the piping. I am only running 50mm pipe. Some of those traditional units need to use some big pipe to flow the air .

Just my 2c

yes you are absolutely correct. the bigger dust systems prefer the 6" diameter ball park. They still perform well at 4" but really start to see degraded performance choked down to 2". I’m not saying they wont do it but the sheer volume the turbine can move is very restricted at that point.

Because I have woodworking, metal working, and blacksmithing tools that require dust collection I am already running a dust extractor that I will likely fit to which ever MPCNC or LRv3 I build. That being said, my miter saw for example still uses a shop vac because it needs the suction more than my other tools.

either way this conversation is a great thought exercise. Crack a VB you deserve it.

Lol, thanks.

There is a youtube show called.“hooked on wood” and he built and is now pushing the benifits of the suction system over the volune system.

In reality the benifit i see for the SUCTION systems VS the VOLUME systems is the size of thr piping as we duscussed. I am using 50mm or 2" pipe.

Like you said, interesting discussion.

I havent checked on that series lately. He was teasing it before and I just havent made my way back to see what he has done

So this new part is a glue-on add-on for the existing latest v1.1 of the Floating Z Dust Shoe. It’s a “universal” part which means it works for all three editions, the Dewalt, Kobalt, and Makita.

Printables download: Printables

It’s a slope-ie, ramp-ie thing to glue onto the bottom of the floating Z shoe body, to minimize the surface area that “sleds” and to keep the bristles from getting splayed out because of the shoe bottoming out.

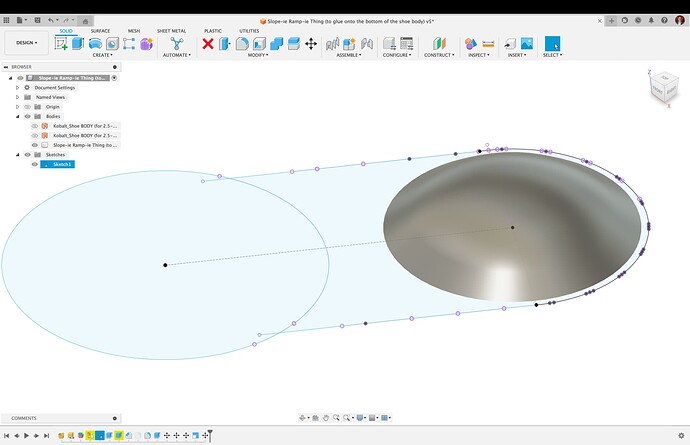

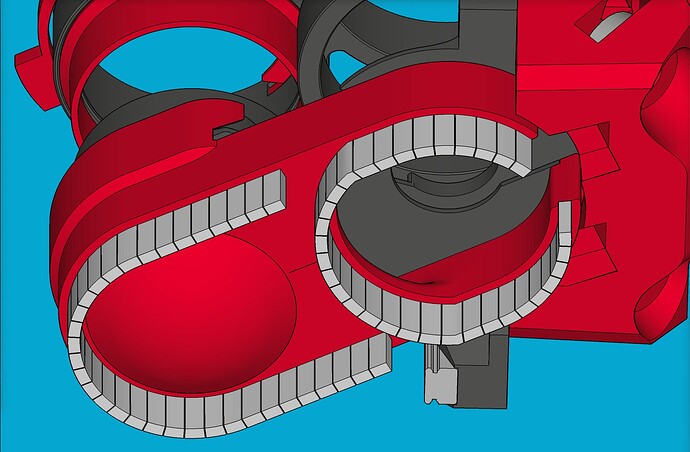

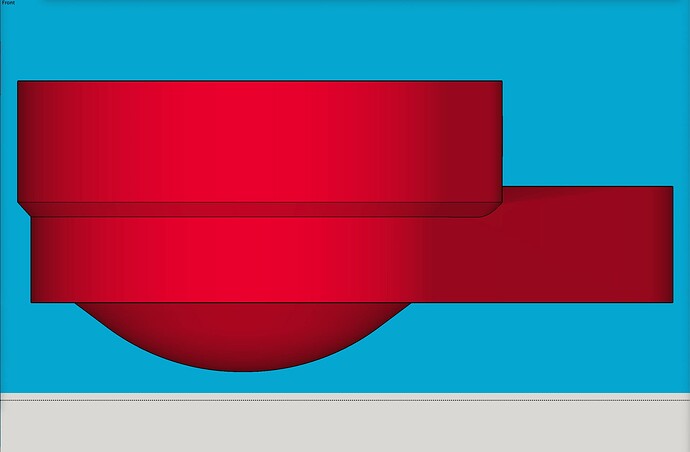

Design in F360 (sketch represents upside-down shoe body, i.e. the bottom of the shoe):

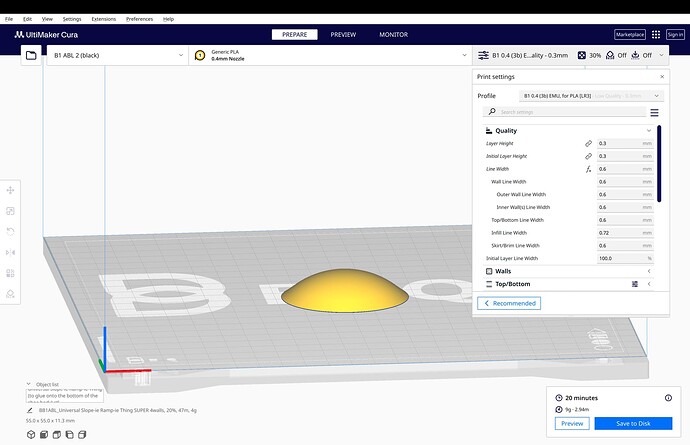

It can be printed in any layer height you wish, with thinner layers meaning a smoother, better slope-ie, ramp-ie thing, but taking longer to print. My 0.3 layer height profile could have printed this in 20 minutes…

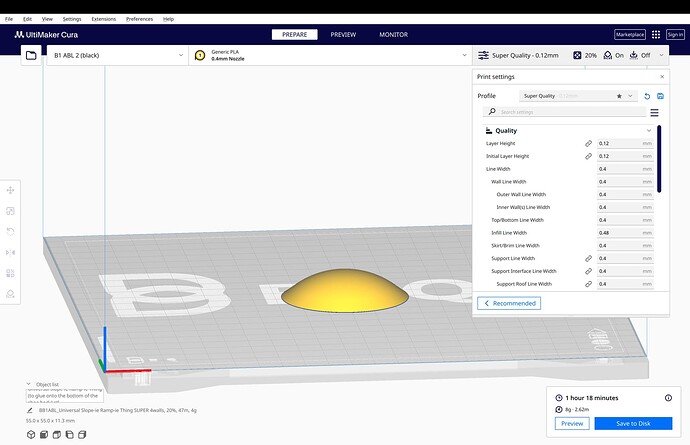

…but I chose to go to the “super quality” to print it with 0.12 layer height, and that showed as taking 1 hour and 18 minutes:

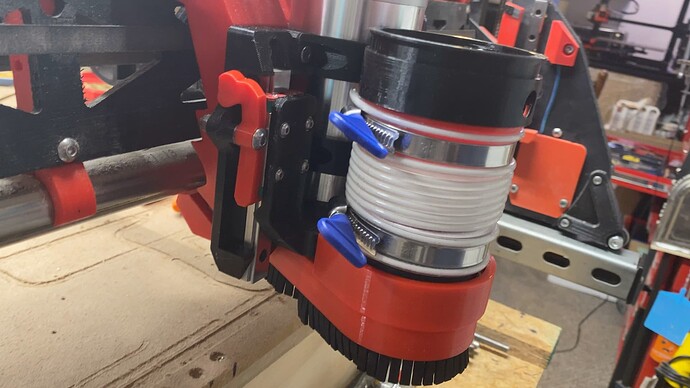

The idea is just print it, and CA glue it onto the bottom of the shoe. It should then sled on the material, and keep the shoe from bottoming out, and keep the bristles functional. If it collides with any obstacle, hopefully it will sled right over it, because of its slope-ie, ramp-ie sides! Below are images showing what the shoe looks like with it added: