Hi, I’m planing to build a 3D printer that is big enough to print a Chello body in one piece, horizontal, laying on the side. I already designed a scalable SolidWorks model. Scalable from violin to chello. I think the FDM process could mimic wood behavior like in classical violin construction.

Would it be possible to have a lowrider type 3d printer?

I have no idea but impossible often seems like a 4 letter word in these forums. I LOVE it! ![]()

It’s an interesting idea, I’ll be following this thread with interest. ![]()

That would take some real skill and attention. It can technically to the same kind of motion as a 3D printer. It also has plenty of room for all the parts. But the trick is making a large surface to adhere the first layer to, keeping it heated, and making the wheels track consistently.

Making the Low Rider print in a small area would not be very hard (to sort of replace an i3 printer with a section of this machine). But making it full size would be an expert level endeavor. I would not expect a great finish and I would suggest a huge nozzle/hot end.

Dui has made the largest MPCNC into a printer (MPCNC made in China thread). Dui also took inspiration from that machine and built his BOx printer. There is another thread here for that printer. Reading through those will give you an idea of what he was thinking about while working through problems.

A large 45 degrees tilted printer, using a belt as printbed might be a another approach. Don’t know if there are any wide enough belts though…

That’s a good point. Do we need a heated bed?

First step of every design is a good design brief. What must, can and shouldn’t have the machine for the task it should fulfill?

I think PLA is ok as a printing material.

PLA does not necessarily need a heated bed. The first layer must stick to the surface, but there are ways to get that without heating.

I’m thinking about a lowrider printer, because I don’t want to move the workpiece around so much. First I wanted to build a long MP3D-Printer, but a back and forth moving, printing portal? Could that be a better way? MP-Portalprinter maybe?

The nozzle seize is not so important, I think. Its not so important for me that the print is fast.

There is a lot of precision needed for 3d printing. I worry about the wheel system… if you don’t have a very good flat & smooth surface then you will likely rip the Chello of the bed long before its finished. I would recommend somthing like the BOx printer and printing it upright.

I’ve seen this printers of course, but the 45 degree wouldn’t work for what I want to try.

I studied the construction of violins and wooden string instruments for this project for a while and I’ve seen the 3d printed violin versions on the internet. In a classic violin is the direction of the wood fibers of the deck very important for the sound of the instrument. And I think FDM can copy this, even in PLA.

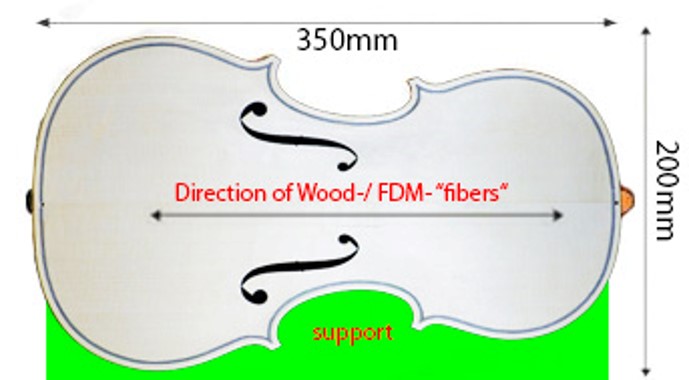

This is the print direction I want to print my instruments in, so that the “fibers” are like in a classical instrument:

A violin is not so big of course. But a chello body is approx. 750mm long

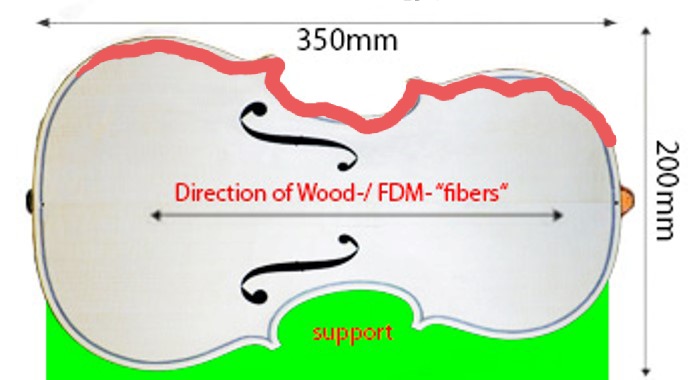

Here is the direction of wood fibers in the deck of a classical instrument, here is where most of the vibration is happening:

The backside is more sturdy.

The f-holes can be cut after printing.

Oh it’s only 750mm then just build a BOx, it has a 900 by 900mm print bed. Here is the build thread.

Though I worry that 3d printing the whole instrument won’t give you the results you want. When I look at the inside of my violin it’s exceptionally smooth. A 3d print will not be. Also plastic has different acoustics then wood. I bet it would work well for electric violins. Or maybe look into wood filled filaments? And print in sections so you can sand the reverb chamber smooth then assemble with glue. More like classic construction.

Though I haven’t studied wood instrument construction so I could be wrong. Just throwing my 2 cents in

It sure helps. First in initial adhesion, but then again when it comes to avoiding warping. Also, if it sticks well enough to print, you will have a heck of a time getting it off. With a heated bed, it will be easier to remove when it cools.

You say that, but the speed is proportional to the volume. And inversely proportional to the build size. The LR can’t move as fast as a prusa (probably 5x slower). And something 200mm on a prusa can take days. Something 800mm would be close to 65x longer. So I am guessing that it could easily take the better part of a year. Add to that the fact that you might have a random power outage every month. Or maybe just the weather would cause warping or something. Faster would mean lower chance of failure and faster recovery from a bad print. There’s no reason any of this free software wouldn’t work forever, but it also has never been tested. You might be the first person to discover a bug that only happens after 2 months of running gcode.

You don’t have to listen to my (possibly conservative) estimates. You can load up a slicer, set a huge bed size and load up your model. You can slice it and see what the estimates are. I would not be surprised if the top speed on a full sized LR is about 25mm/s for reliable performance, so set that too. And then see what a larger nozzle will do to that time.

Honestly, this is at least an advanced printing project, if not a research level of project. If you haven’t done much printing already, it will be a huge money suck.

Plus I think you would need multi material… most 3d printers wouldn’t bridge well enough to print the chello’s side wall without support… so if you print it on its side the top side wall will fail unless you have internal support(shown here in red). But then you would need to remove that support through the F holes… only way I can think to do that is by desloving the supports. Wotch would require being able to print 2 different filaments in the same print.

Generally, I would consider this ill-advised if you ever want to PLAY the instrument. If it’s a display…

-

This is going to take a VERY long time to print. Even with a 1mm or larger “volcano” nozzle, this is ambitious. Once you go to that size nozzle and the layer height it allows, your surface finish will be rather bad. I’m guessing that your print time will be measured in weeks, if not months. Now imagine how you’re going to feel if it runs out of material, or the print messes up in another way 6 weeks after you start… Oh, and you’ll need supports in the F holes, too, or else you’re going to be printing on air, which doesn’t work so great.

-

Uh… you’re building a cnc. Why not cut the body pieces out of actual wood? It probably cost less in the end. You could do the top and bottom as sheets, and if you don’t want to bend the side pieces, you can cut those from layers of thin material and laminate them. In almost every respect the finished product will be superior, unless you want to use wild dayglo colours or specialty plastic, of course. Still, if you’re insisting on plastic, cut sheet material will be faster, more reliable and consistent. I guess it doesn’t qualify as “3d printed” but…

-

I don’t know how repeatable the Lowrider’s motion system is. It seems to me that the wheels may allow for some variance between layers. It’s going to be quite accurate for dozens of passes, but here’ we’re talking hundreds. This is, of course dependent on your build quality, but I think that the Primo can be built to this size with the repeatability more consistent more easily.

-

If it MUST be 3D printed… You can specify your solid fill angles. They default to linear at alternating 45 degrees, but you can have them all parallel at 0 degrees. This would allow you to lay down the print on the face of the instrument and still have your “fibres” run the length of the instrument. you could then print in 2 halves and bond them together with a heat gun or fine tipped soldering iron. I would consider this the only possible way to achieve acceptable results.

I’ve read several books on the luthier’s craft, and I have a LOT of respect for the knowledge and expertise that goes into making an instrument of this sort. It would be a fascinating project.

Didn’t a university 3d print a boat not long ago? Sounds like this is some research…maybe they’d be willing to print a violin for you? Might have to make a donation to the program, but maybe you could get a first piece and decide whether you want to go through all the trouble.

Unfortunately, I think Jeff is a lot closer to right than wrong. I’ve seen some sheet good through cut programs calculated at Days for some furniture. Granted, the cuts were really not optimized, and it was a bunch of small parts…but we’re talking 1/8 endmill taking 4 passes around the contours and some pockets to get milled with finish passes. Your printer is going to have to make a LOT more trips than that, and there will be several contours(walls) stacked next to each other, plus wherever you need infill or support material.

That said, if you do it and get it working I want some time lapse! I learn more from people here than they learn from me, that’s for sure. So I’ll be watching closely if you take a shot at it.

This one?: The revolution of 3D printed boat: meet the 3Dirigo (sculpteo.com)

(Time lapse included)

What this country needs is a good $20K 3D printed airplane!

Yeah that’s the one. But if it printed the boat in 72 hours, it might not be suitable for such a *small *print

There’s always something! ![]()

Hello GulbiDesign, here are my two cents since I have some experience on big prints and since pleople invoked me

Do you need a heat bed? Yes, absolutely. Even with PLA you can’t get away with warping once your print is bigger than 300mm in one dimension, from my experience at least warping is unavoidable and will surely ruin your print. Also, it makes removing the print a million times easier, and it helps with bed adhesion for the first layer, though the first layer is rarely a big issue with glass beds.

So yeah, it’s necessary. It’s not that hard to build anyway, but I guess it might be expensive to do in Europe.

The nozzle size is VERY important. with bigger size comes stronger prints, and I guess a Cello might experience some big forces coming from the strings.

Plus the times to print goes exponentially with nozzle size, so printing a cello body with a 0.4mm nozzle will take you months, which means that there is very little chance your print will succeed, no machine that I know of is able to print reliably for that long. At least I haven’t seen one and you should assume yours won’t.

Always try to keep your print below the 48hours limit, it’s already a huge bummer when it fails after one day and a half, so I can’t imagine the feeling it would be for it to fail after three weeks…

As for how to actually print the body, I think the way you envison things is fine as far as the orientation, but it seems to me like you forgot that the thing is hollow, which will be a huge problem when you’ll try to print the top side. I see three possibilities here:

-Design the cello to be printable entirely without inside cavities supports. I guess it will affect the sound, but who knows, maybe it will give some cool effect.

-Use water soluble supports, that implies two print heads.

-Cut it in half, print them one at a time and then glue them together. I would chose this one since it would give two identical parts with identical characteristics, plus it lowers the print failure risks. It’s by far the easiest way.

You also need to think about filament, one 1kg spool won’t be enough so you want to check the availability of bigger spools wherever you live.

Now, what platform to use:

-The LowRider? in my opinion it’s a no go, you need too much print height for this and the speed, accelerations, accuracy, and pretty much anything else won’t be suitable

-The MP3DP? Might be possible, but only at very low speeds. The reason is that it is a moving bed, which will be very heavy in the first place and will become heavier and heavier the more plastic you extrude on it.

-The MPCNC: in my opinion a much better choice here, it can work and it can be relatively fast and reliable with really decent quality.

One more important point: it would be much better to design the cello with 3D printing in mind from the beginning. using shapes that can be printed without overhangs as much as possible, variable thicknesses to make up more strenght, etc. Generally if you want good results with 3D printing the part needs to be designed with 3D printing limitations in mind.

In my opinion, you need to familiarize yourself first with 3D printing. It seems to me like you’re not really experienced in this field, which is ok, but before tackling this kind of project you need to really do your homework first, otherwise you’ll invest a lot of money and be really disappointed. Anyway, I’ll be glad to help if you have any question or if you start a build

Good luck!

I thought about building a MPCNC printer for the project first, but thought that it wouldn’t be accurate enough, because I read that the MPcnc isn’t so good as a printer.

Good to know that you think that would be a working way to do it. A heated bed isn’t so expensive in Germany. We get a lot of stuff from China. The costs of getting stuff from China is mostly lower than getting something from France. Often it’s even 0 shipping costs on EBay. Getting stuff from America is very expensive for Europeans.

Thank you for your Tipps and opinions on the project. I’ve seen your big box printer and I think it’s quite an achievement. Well done!

For me this is just a little hobby side project. I have this little idea that I wanna try at home in my spare time. It’s funny for me that you think that it seems, that I have no experience in 3D printing. Because quite the opposite is true, but my experience are more in a industrial environment with big machines. I have approx. 15 years experience in designing stuff for industrial 3d printing, injection molding, metal casting, welding, sheet metal and tube laser cutting… Mostly with SolidWorks. In the past I worked for big companies and have my little own:

https://gulbidesign.de/

The side is in German, but there are a lot of pictures.

But your right that my experience with “home made machines” is not so big. Normally if something goes wrong with a machine I call a service technician ![]()

And yes, I think you are very right that the instrument must be designed for 3d printing in mind. Like a real violin is designed for being built in wood. I don’t wanna print just a copy of an existing Stradivarius.

I would like to make a playable, 3D printed instrument, by my own design. And I think here is where the strongpoints of 3d printing are. It’s possible to build in specific inner structures, like channels to effect the working of the instrument.

Yes PLA differs from wood, that is used in old instruments. That’s why it’s have to be designed with PLA in mind for this task.

I think I start with a violin for trying it out but with a chello as a goal in mind.

I don’t think you should take it personal that people scrutinize the challenges with printing a hollow object. People have all sorts of crazy ideas (speaking for my self at least!) and it’s not easy for other peers to know each others level of skill. It was challenging for me figure out how to cut a steel pipe perfectly straight, while others in this forum build cars and even planes from scratch…