I had to jump in. I just ordered the steel for my water table. Super excited to get cutting again. Kind of a bummer of a shop, customer service was alllllmost nonexistent and after placing a $350 order I asked about smaller cut offs discount bin or anything I could buy for test cuts. His reply “we don’t have scrap here!” Such an odd reply. Any steel place I have been too so far loves to sell cut-offs.

Wow, yes I can hardly imagine a steel seller who does not have some offcuts to sell!

And he was sort of offended or snobby about it. That is my second shop nearest me that was not all that fun to spend money at. I found a super cool spot in Oakland, I need to go back there. They had sooooo much stuff and a whole bunch of scrap bins everywhere. Stuff at like $5 a pound.

I can’t wait to compare the prices to a couple of the big online metal suppliers. hopefully this evening.

$5 per pound is a good price.

Yeah the down side is we pulled out a piece that turned out to be hardened or something. We could barely even drill through it.

Wow! Yep that would be frustrating downside

That just means they don’t sell their off cuts as “scrap”.

Ohhhhh that makes more sense. I guess that is how I would do it, until I had a giant bin of scrap. Thanks that actually makes a ton of sense. They run a tight ship.

So I went back to pickup my order. There are three signs on the desk “we do not sell scraps”  That explains why he had some attitude.

That explains why he had some attitude.

But wait, there’s more.

I pay for my order, drive around back to pick it up. The guy loading my order says “Hey one piece is a bit short, we can sell it to you as scrap or I will cut the piece you need”.  The exact piece I said I don’t need a full 5’ of it. Head back in to get a refund for taking a scrap, signed the receipt on the “we don’t sell scrap sign”. Overall better experience today, will probably go back.

The exact piece I said I don’t need a full 5’ of it. Head back in to get a refund for taking a scrap, signed the receipt on the “we don’t sell scrap sign”. Overall better experience today, will probably go back.

Sorry for derailing your thread, Doug.

Back to the regularly scheduled program.

That’s hilarious and entertaining! And totally pertinent to a plasma cutting thread.

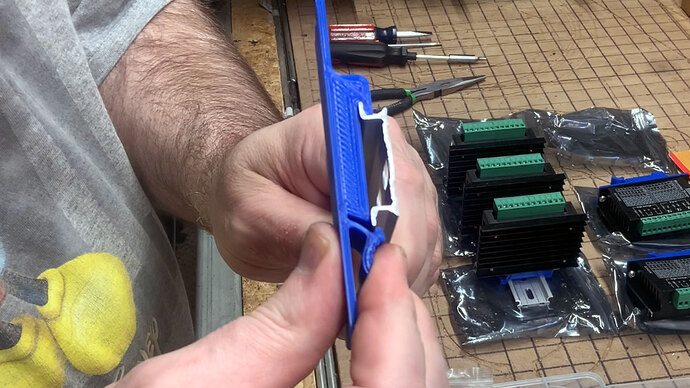

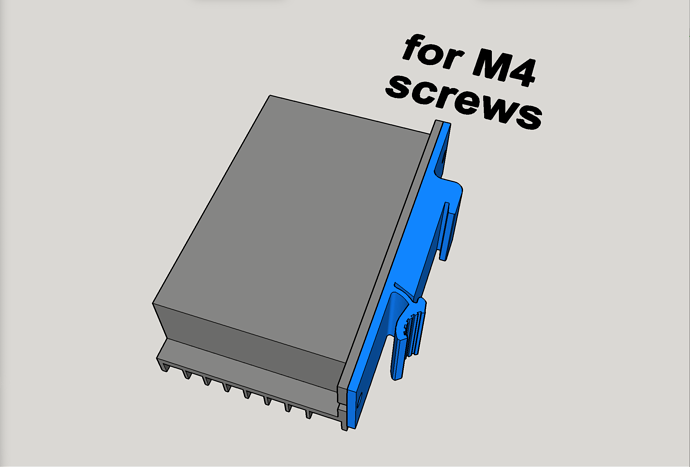

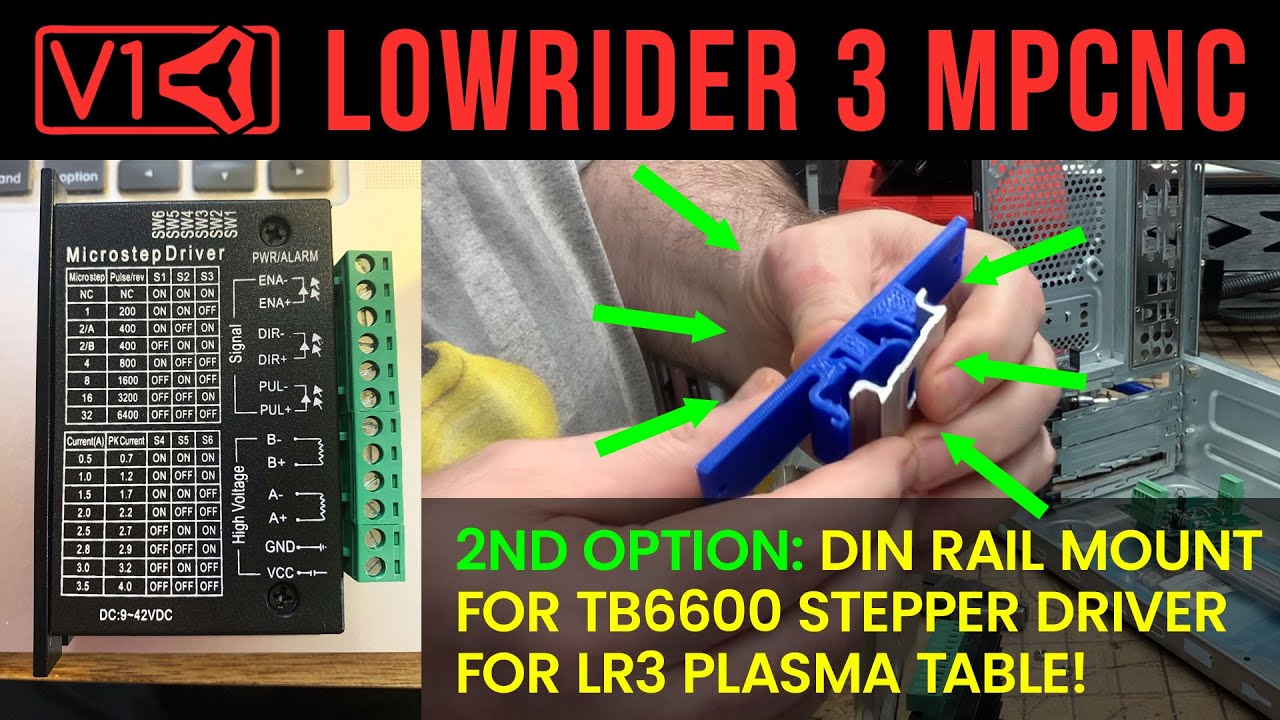

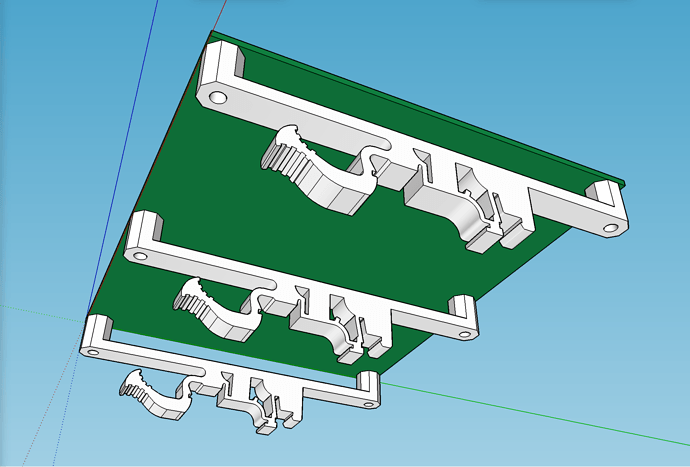

(Option 1 of 2) Printed DIN rail mount for TB6600 stepper motor driver.

Download: Printables

- Designed for M4 screws.

- Print as oriented.

- Prints with no supports.

My intended use for these is for my LowRider v3 CNC plasma table setup.

Change log:

- November 16, 2022, 12:29 am (EST): initial posting of v1.0.5.

My PayPal tip jar: https://paypal.me/design8studio

Various LowRider 3 CNC remixes:

View all my models and remixes on Printables:

I posted this on the LinuxCNC forum, but adding here too.

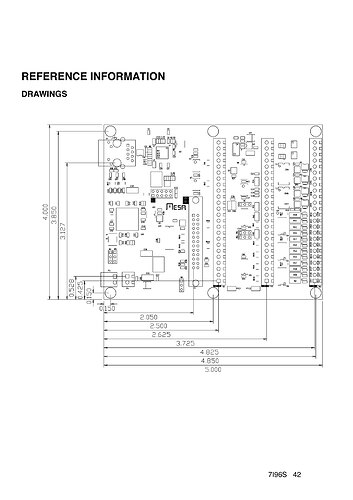

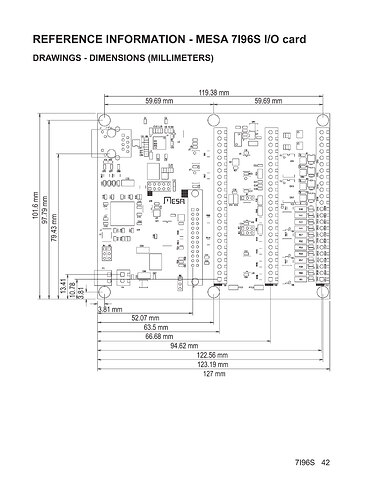

MESA 7i96s Dimensions in both inches and millimeters

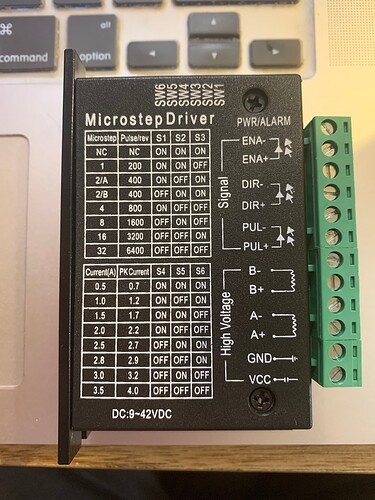

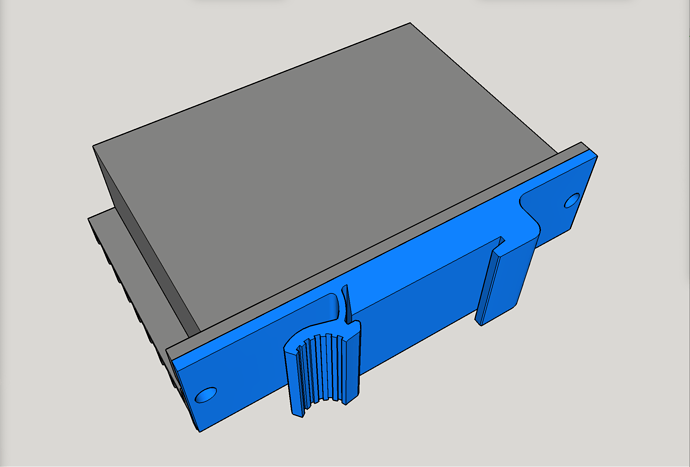

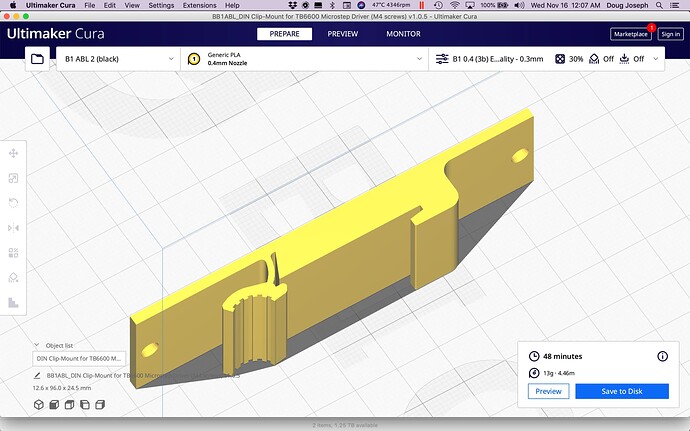

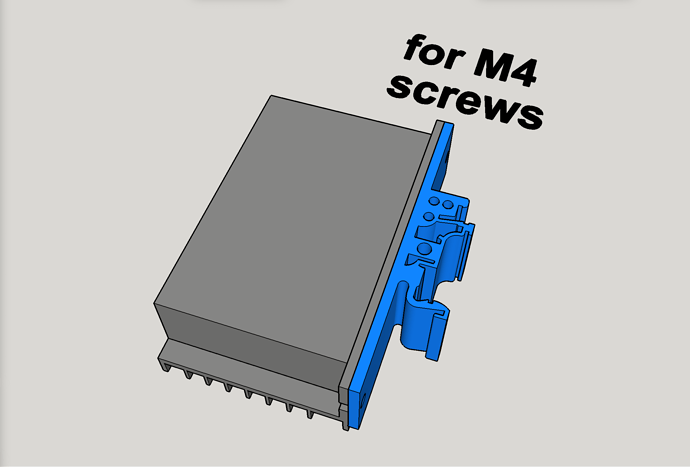

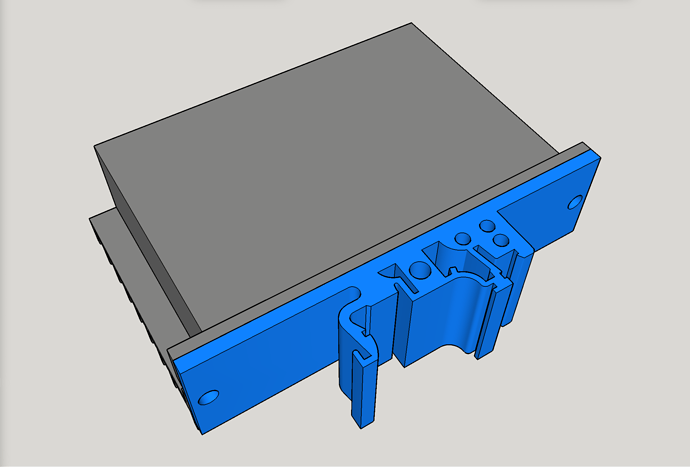

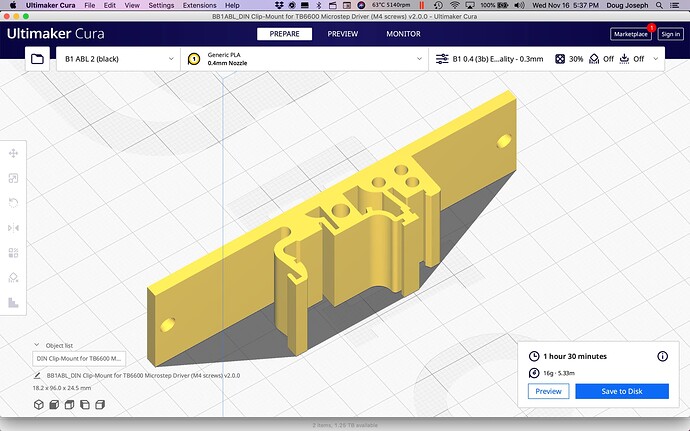

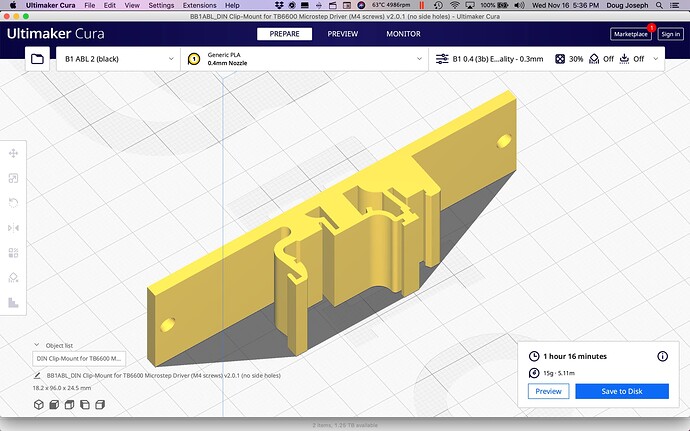

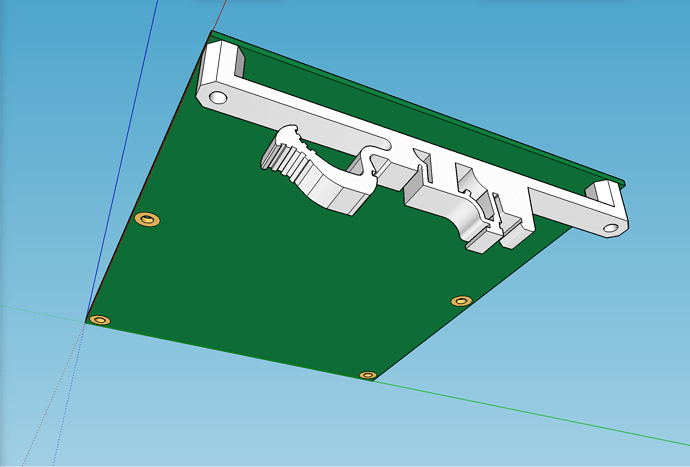

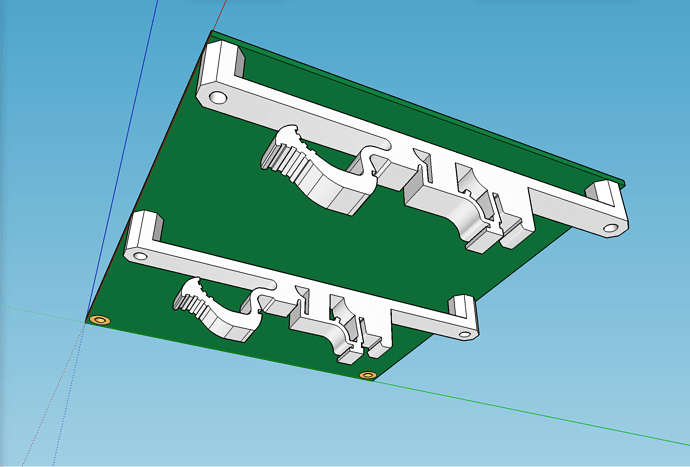

(Option 2 of 2) DIN Rail Clip-Mounts for TB6600 Microstep Driver (v2.0.0 & 2.0.1)

Download: Printables

This is the second of two options for DIN rail mounts for a TB6600 stepper motor driver. The other (1.0.5) is available here .

- Designed for M4 screws.

- Print as oriented.

- Prints with no supports.

My intended use for these is for my LowRider v3 CNC plasma table setup. It’s basically a LowRider v3 that’s tweaked and modified to hold a plasma torch instead of a router. More on that here . You can also read about my router-based LowRider, which was originally built as a v2 , and later upgraded to v3 .

Note:

This is a remix of a design by Claus Dieners (February 18, 2022) that I found on GrabCad . His design had side holes, the purpose of which I do not know. Removing them from my remix made it print quicker (15 minutes less print time) and used less plastic (less perimeter walling). Since I don’t know the purpose of the side holes I am making two versions available, one with holes (2.0.0) and one without (2.0.1). If you don’t need the side holes, save time and print without them.

Change log:

- November 17, 2022, 2:20 am (EST): initial posting of v2.0.0 and 2.0.1.

My PayPal tip jar: https://paypal.me/design8studio

Various LowRider 3 CNC remixes:

View all my models and remixes on Printables:

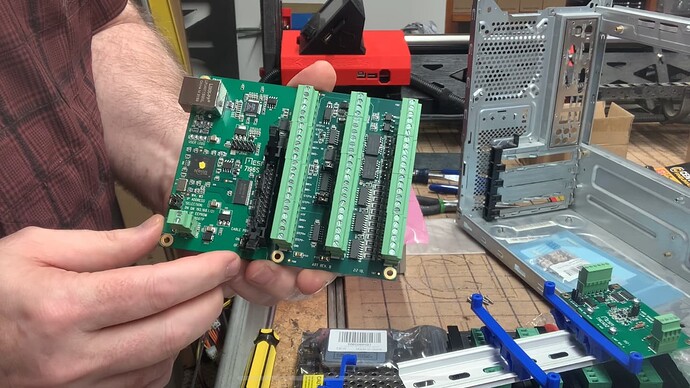

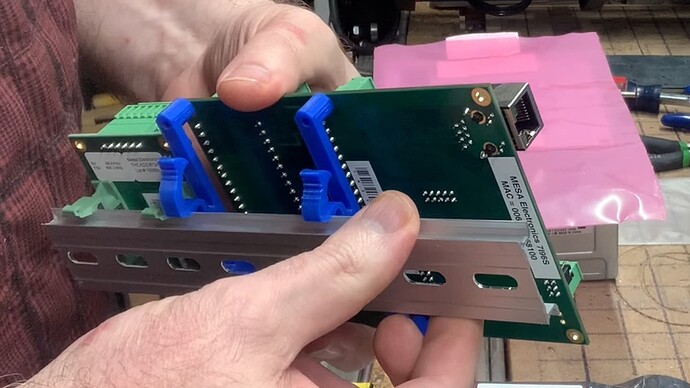

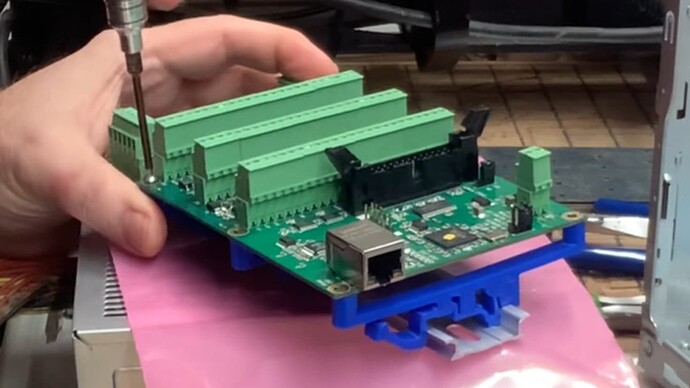

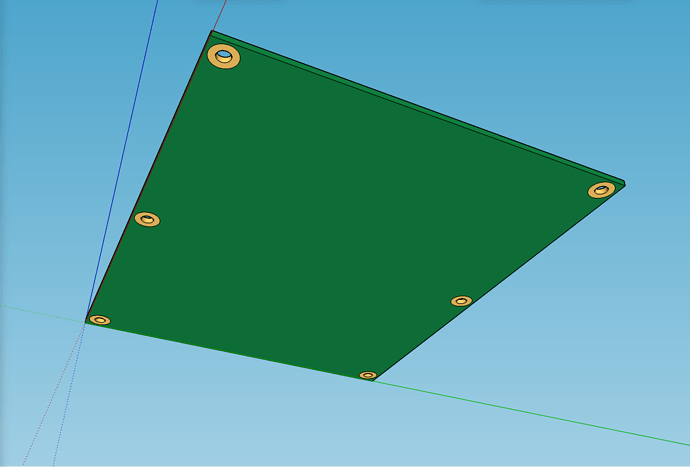

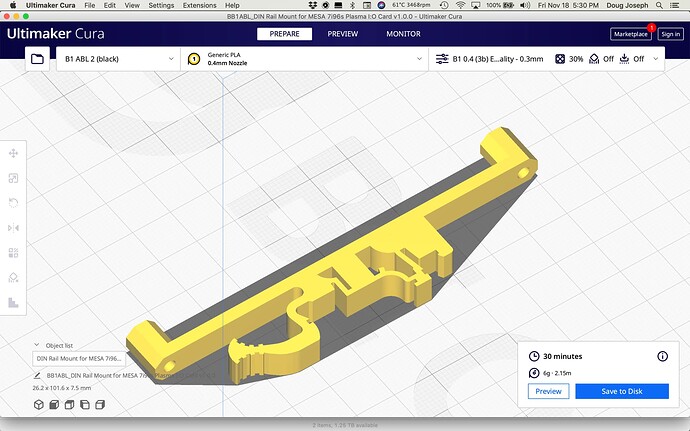

3D-printed DIN Rail Mount for MESA 7i96S I/O card for Plasma CNC

DOWNLOAD: Printables

This is a DIN Rail Mount for the MESA Electronics 7i96S I/O card for my Plasma CNC based on the LowRider v3 motion system.

- Designed for six M3 screws.

- Print as oriented.

- Prints with no supports.

Note:

This is a remix of a design by Claus Dieners (February 18, 2022) that I found on GrabCad. His design had side holes, the purpose of which I do not know. Removing them from my remix made it print quicker (15 minutes less print time) and used less plastic (less perimeter walling). If you need a version with the side holes, let me know in the comments or by a direct message.

Change log:

- November 18, 2022, 7:50 pm (EST): initial posting of v1.0.1.

My PayPal tip jar: https://paypal.me/design8studio

Various LowRider 3 CNC remixes:

View all my models and remixes on Printables:

Your having so much fun with this din mount. It makes me want to try some on my tool wall for some prototype stuff.

Being able to quickly remix and print needed custom items is such a cool thing. We live in amazing times.

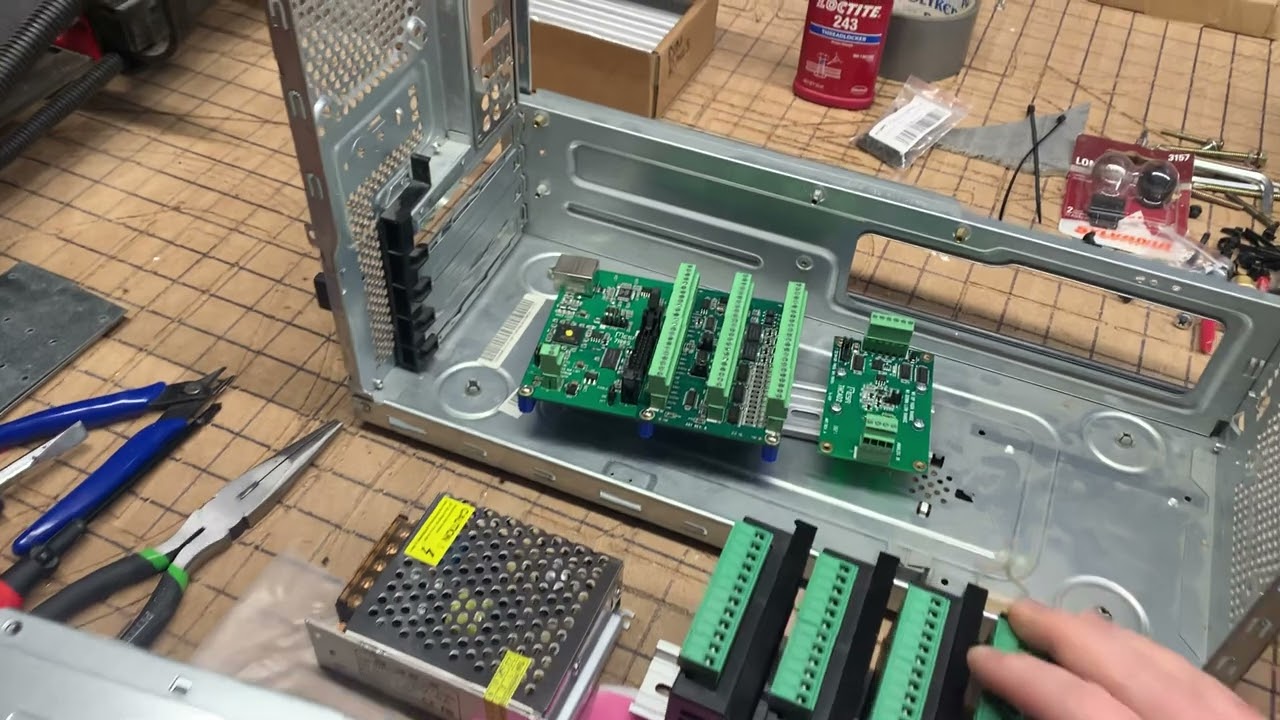

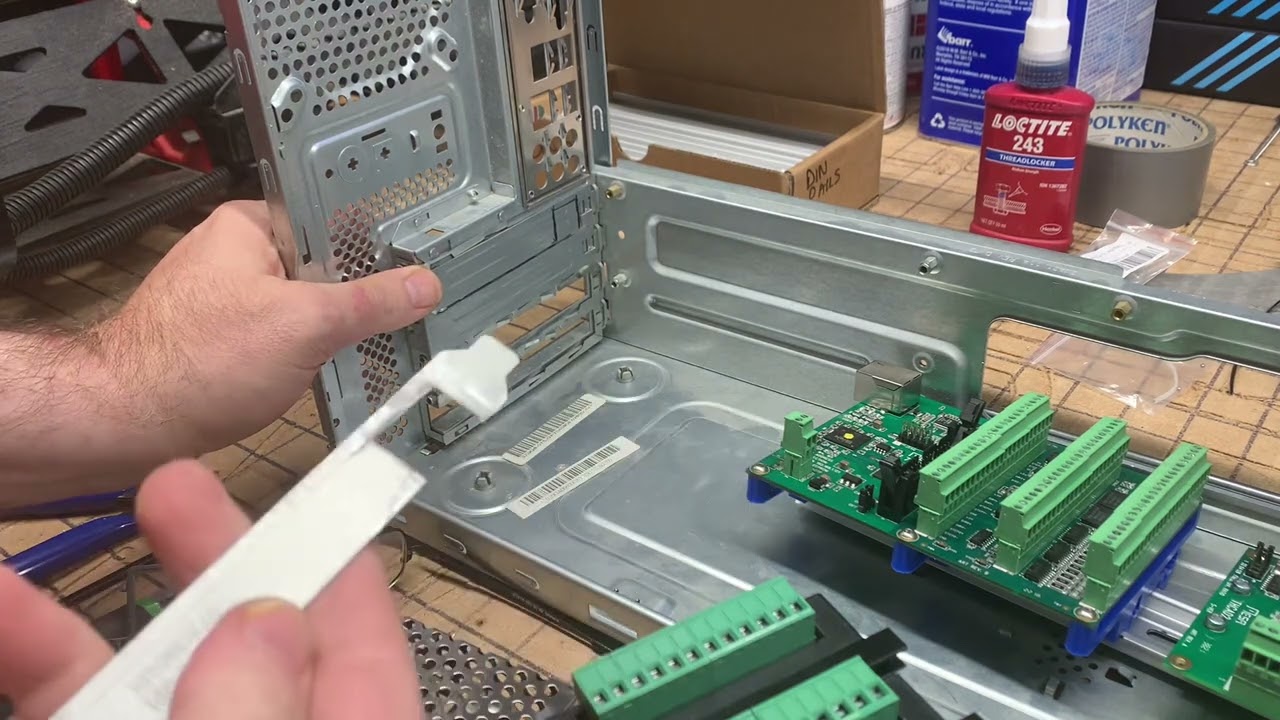

Two more short video updates, both regarding the ongoing control box build, based on “recycled” use of an old PC desktop tower, repurposed for the plasma CNC electronics.

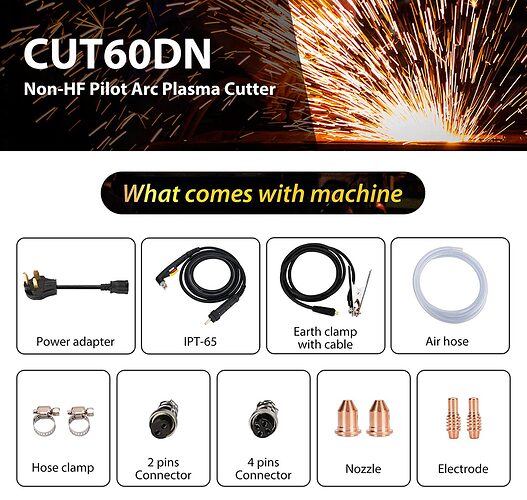

Posting here for myself (and anyone else interested) some details, port schematics, & pics about the plasma cutter & machine torch I purchased for this project.

Plasma cutter

| Brand | Hynade |

| Model | CUT60-DN |

| Type of plasma cutter | Non-High Frequency Pilot Arc |

| Purchase link | https://amzn.to/3Xw3agV |

| Arc Voltage Output (see pic for more) | Pin1: [+], Pin2: [-], Ratio 1:1 |

| Signal Control Port (see pic for more) | 1/2: [Start Control Signal Input], 3/4: [Arc Starting Signal Output] |

| Input voltage: | AC 110/220V +/-15% |

| Output current: | 55 Amps Rated input capacity: 8.6 KVA |

| Output Current range: | 15A-55A |

| Efficiency: | 85% |

| Duty cycle: | 60% @ 55Amps 75℉ |

| Insulation class: | B |

| Max cutting thickness: | 25mm@55A 220V 70PSI (0.6Mpa) |

| Quality Cutting thickness: | 20mm@55A 220V 70PSI |

| Cutting speed: | 200mm/min at 20mm thick metal 70PSI (Air Pressure) |

| HF Arc starting: | Non-HF Pilot Arc, Non-Touch metal |

| IGBT (insulated-gate bipolar transistor) | Yes |

| Automatic voltage adaptation | Yes |

| 2T/4T | Yes |

| CNC ready (comm ports on back) | Yes |

| Low noise | Yes |

| Fan exhaust | Yes |

| Machine (straight) torch compatibility | Yes, PTM80 |

What comes with the machine:

- 120v to 240v plug adapter

- IPT-65 handheld torch with cable

- Grounding clamp with cable

- Air hose

- Hose clamps

- 2-pin connector (aviation style)

- 4-pin connector (aviation style)

- Nozzle replacement x2

- Electrode replacement x2

Q&A:

A: When adjust to around 45A ,can allow a 100% duty cycle for CNC cutting work (source: seller)

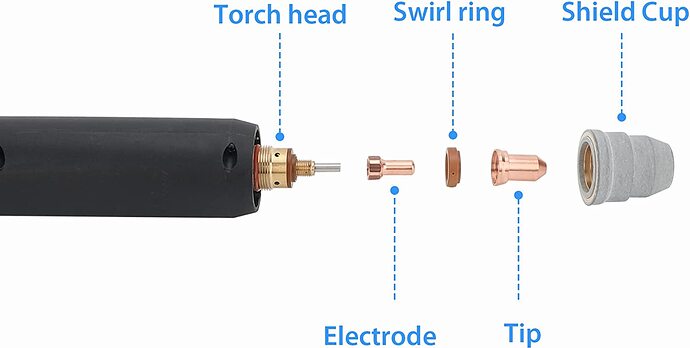

Machine Torch info:

| Brand | Hynade |

| Model | PTM80 CNC Plasma Cutting Torch |

| Purchase link | https://amzn.to/3XCORHE |

So, I found a Fusion 360 Post Processor for “LinuxCNC (EMC2)” but it was for use with milling, not for plasma cutting. I later found two that are for plasma (see post below).